Kia Optima DL3: Engine And Transaxle Assembly / Engine And Transaxle Assembly

Repair procedures

| Removal |

|

|

| 1. |

Remove the engine cover. (Refer to Engine and Transaxle Assembly - "Engine Cover") |

| 2. |

Disconnect the battery negative terminal. |

| 3. |

Remove the battery and battery tray. (Refer to Engine Electrical System - "Battery") |

| 4. |

Remove the air cleaner assembly. (Refer to Intake and Exhaust System - "Air Cleaner") |

| 5. |

Remove the engine room under cover. (Refer to Engine and Transaxle Assembly - "Engine Room Under Cover") |

| 6. |

Drain the engine coolant. (Refer to Cooling System - "Coolant") |

| 7. |

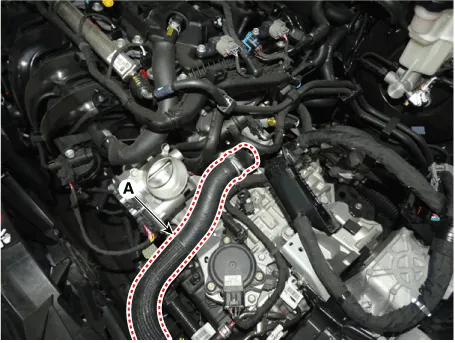

Disconnect the radiator upper hose (A).

|

| 8. |

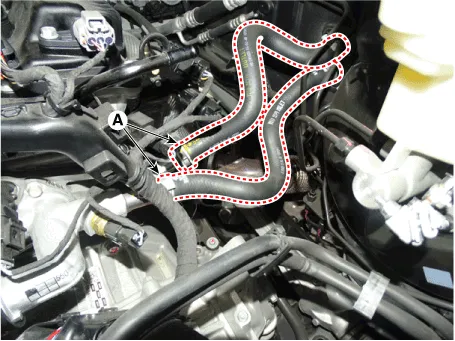

Disconnect the radiator lower hose (A).

|

| 9. |

Recover the refrigerant and then remove the high pressure pipe and low pressure pipe. (Refer to Heating, Ventilation Air conditioning - "Compressor") |

| 10. |

Disconnect the wire harness connectors, control cables and ATF cooler hoses (A/T only) from the transaxle. (Refer to Automatic Transaxle System - "Automatic transaxle") |

| 11. |

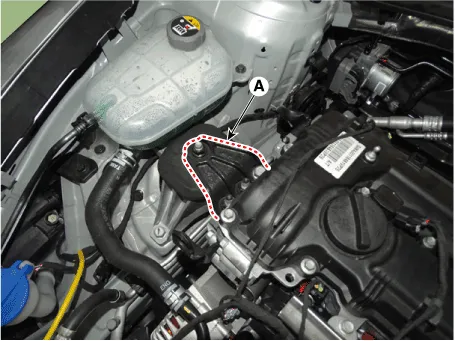

Disconnect the heater hose (A).

|

| 12. |

Disconnect the brake booster vacuum hose (A).

|

| 13. |

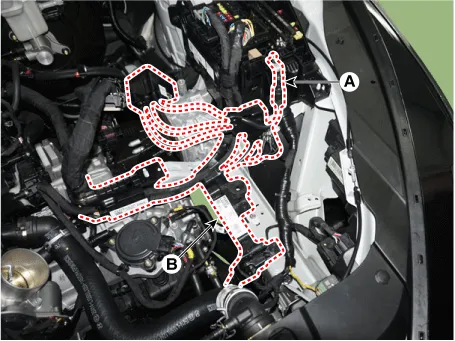

Disconnect the fuel hose (A) and the purge control solenoid valve (PCSV) hose (B).

|

| 14. |

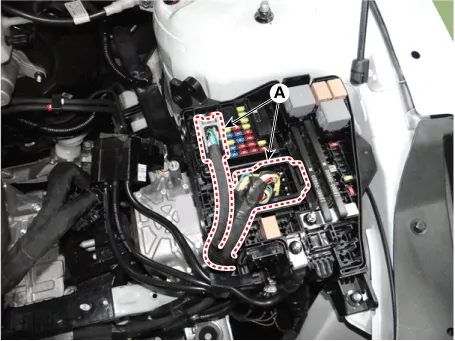

Remove the wiring harness from the engine room.

|

| 15. |

Remove the front muffler. (Refer to Intake and Exhaust System - "Muffler") |

| 16. |

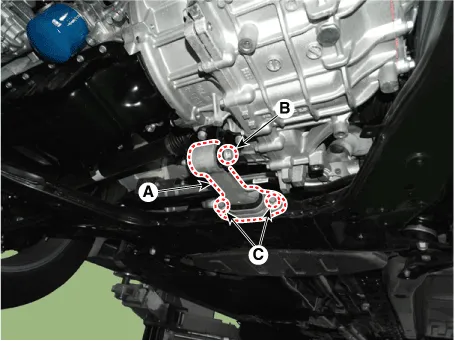

Remove the roll rod bracket (A).

|

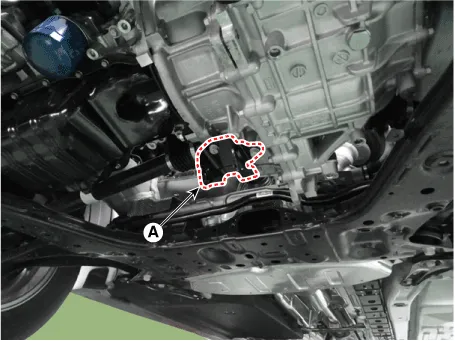

| 17. |

Remove the roll rod mounting support bracket (A).

|

| 18. |

Remove the sub frame. (Refer to Suspension system - "Sub Frame") |

| 19. |

Support the engine and transaxle assembly with a lift table. |

| 20. |

Disconnect the engine ground cable.

|

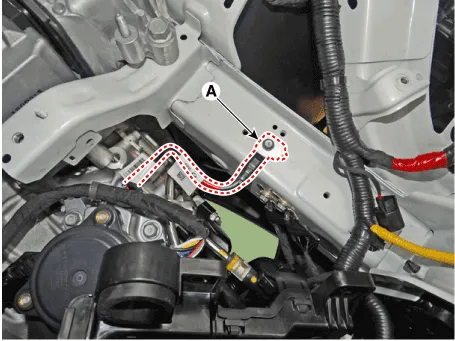

| 21. |

Remove the engine mounting support bracket (A).

|

| 22. |

Disconnect the transaxle ground line (A).

|

| 23. |

Remove the mounting side pannel packing (A).

|

| 24. |

Remove the transaxle mounting bolts (A).

|

| 25. |

Remove the engine and transaxle assembly (A) by lifting vehicle.

|

| Installation |

Installation is in the reverse order of removal.

Perform the following :

| • |

Refill engine with engine oil. |

| • |

Refill transaxle with fluid. |

| • |

Refill radiator and reservoir tank with engine coolant. |

| • |

Place heater control knob on "HOT" position. |

| • |

Bleed air from the cooling system. |

| – |

Start engine and let it run until it warms up. (until the radiator fan operates 3 or 4 times.) |

| – |

Turn Off the engine. Check the level in the radiator, add coolant if needed. This will allow trapped air to be removed from the cooling system. |

| – |

Put radiator cap on tightly, then run the engine again and check for leaks. |

| • |

Clean battery posts and cable terminals with sandpaper assemble them, then apply grease to prevent corrosion. |

| • |

Inspect for fuel leakage. |

| – |

After assemble the fuel line, turn on the ignition switch (do not operate the starter) so that the fuel pump runs for approximately two seconds and fuel line pressurizes. |

| – |

Repeat this operation two or three times, then check for fuel leakage at any point in the fuel line. |

Components and components location Components 1. Transaxle mounting bracket 2. Roll rod bracket 3. Engine mounting bracket 4.

Other information:

Kia Optima DL3 2019-2025 Service and Repair Manual: Relaxion Comfort Seat

Components and components location Component Location 1. Relaxion comfort switch 2. Walk-in switch 3. Relaxion comfort seat unit (RCSU) Schematic diagrams Connector and Terminal Function Pin Function Connector A Co

Kia Optima DL3 2019-2025 Service and Repair Manual: Receiver-Drier

Repair procedures Replacement 1. Remove the condenser. 2. Remove the cap (A) on the bottom of the condenser with a L wrench. Tightening torque : 9.81 - 14.71 N.

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Front Door Outside Handle

- Body (Interior and Exterior)

- Charging System

- New on site

- Most important about car