Kia Optima DL3: Cylinder Block / Crankshaft

Components and components location

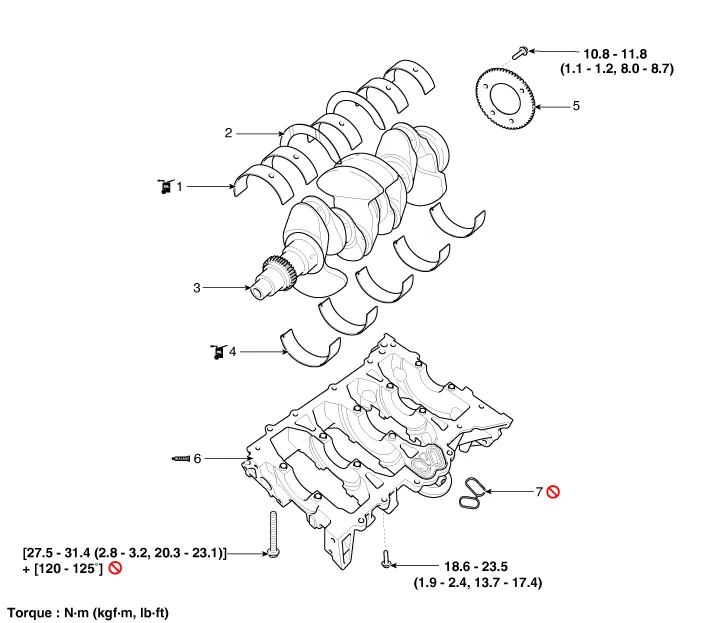

| Components |

| 1. Crankshaft upper bearing

2. Crankshaft thrust bearing 3. Crankshaft 4. Crankshaft lower bearing |

5. Crankshaft position sensor

(CKPS) wheel 6. Lower crankcase 7. Gasket |

Repair procedures

| Disassembly |

|

|

| 1. |

Remove the engine assembly from the vehicle. (Refer to Engine and Transaxle Assembly - “Engine and Transaxle Assembly”) |

| 2. |

Remove the transaxle assembly from the engine assembly. (Refer to Automatic Transaxle System - "Automatic Transaxle") |

| 3. |

Remove the drive plate. (Refer to Cylinder Block - "Drive Plate") |

| 4. |

Remove the rear oil seal. (Refer to Cylinder Block - “Rear Oil Seal”) |

| 5. |

Install the engine to engine stand for disassembly. |

| 6. |

Remove the timing chain. (Refer to Timing System - “Timing Chain”) |

| 7. |

Remove the water pump assembly. (Refer to Cooling System - “Water Pump”) |

| 8. |

Remove the water inlet fitting and the thermostat assembly. (Refer to Cooling System - “Thermostat“) |

| 9. |

Remove the intake manifold. (Refer to Intake and Exhaust System - "Intake Manifold") |

| 10. |

Remove the A/C compressor. (Refer to Heating, Ventilation Air conditioning -"Compressor") |

| 11. |

Remove the exhaust manifold. (Refer to Intake and Exhaust System - "Exhaust Manifold") |

| 12. |

Remove the cylinder head assembly. (Refer to Cylinder Head Assembly - "Cylinder Head") |

| 13. |

Remove the oil filter. (Refer to Lubrication System - “Engine Oil”) |

| 14. |

Remove the oil screen. (Refer to Lubrication System - “Oil Pan”) |

| 15. |

Remove the piston and connecting rod assemblies. (Refer to Cylinder Block - "Piston and Connecting Rod") |

| 16. |

Check the crankshaft bearing oil clearance. |

| 17. |

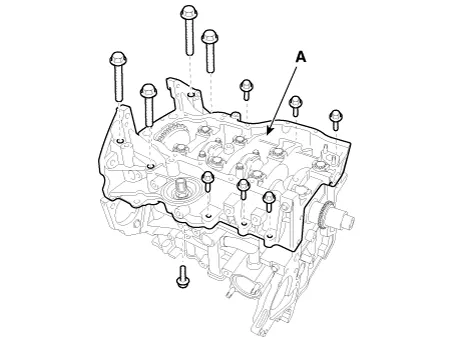

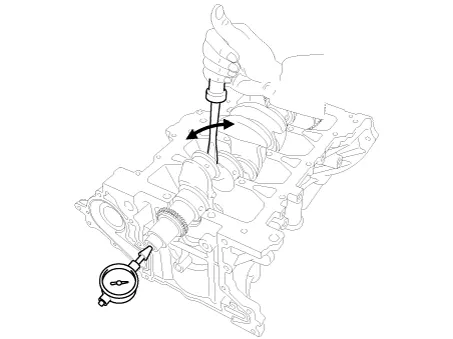

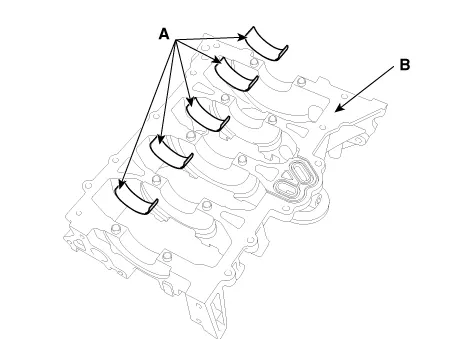

Remove the lower crankcase (A).

|

| 18. |

Check the crankshaft end play. |

| 19. |

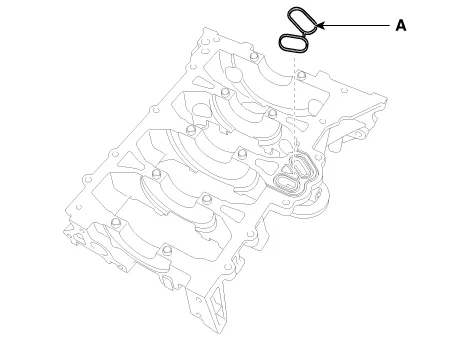

Lift the crankshaft (A) out of the engine, being careful not to damage journals.

|

| Inspection |

| 1. |

Check the crankshaft bearing oil clearance.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2. |

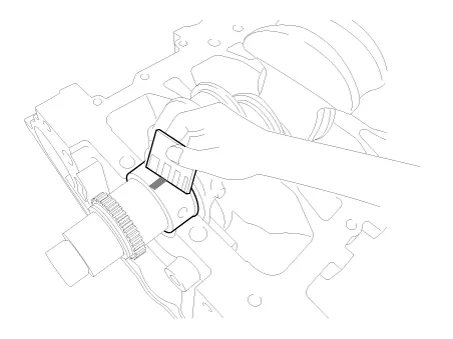

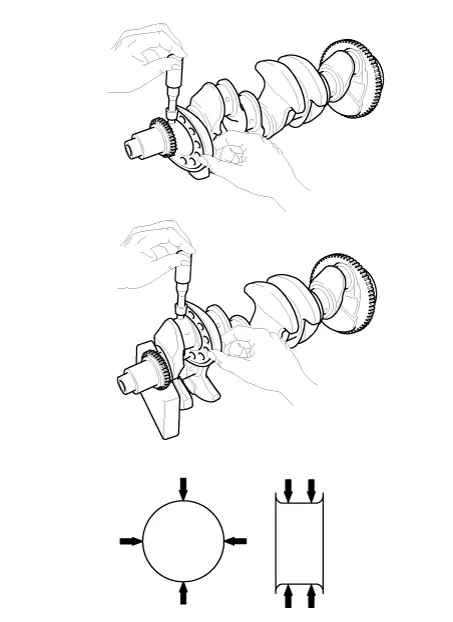

Check crankshaft end play. Using a dial indicator, measure the thrust clearance while prying the crankshaft back and forth with a screwdriver. If the end play is greater than maximum, replace the center bearing.

|

| 3. |

Inspect main journals and crank pins. Using a micrometer, measure the diameter of each main journal and crank pin.

|

| Reassembly |

|

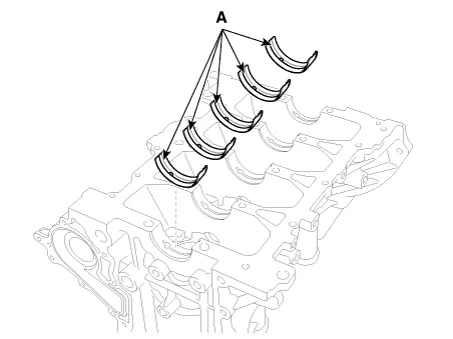

| 1. |

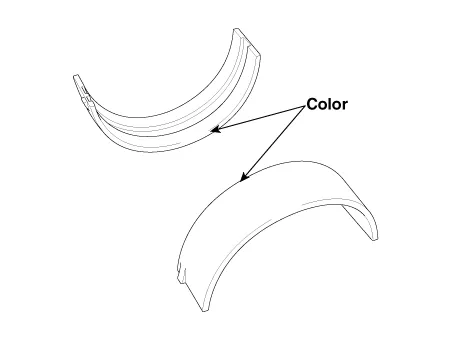

Install the crankshaft main bearings.

|

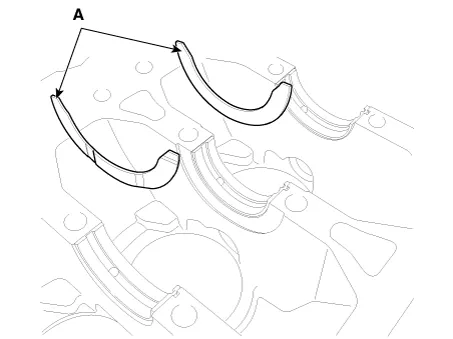

| 2. |

Install the thrust bearings. Install the 2 thrust bearings (A) on both sides of the No.3 journal of the cylinder block with the oil groove facing out.

|

| 3. |

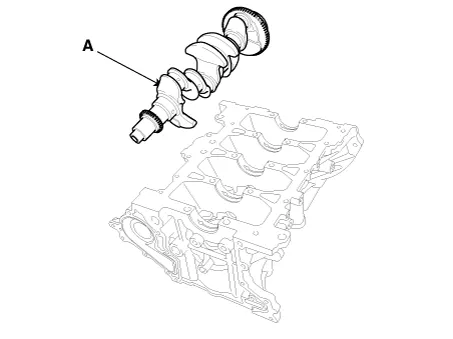

Place the crankshaft (A) on the cylinder block.

|

| 4. |

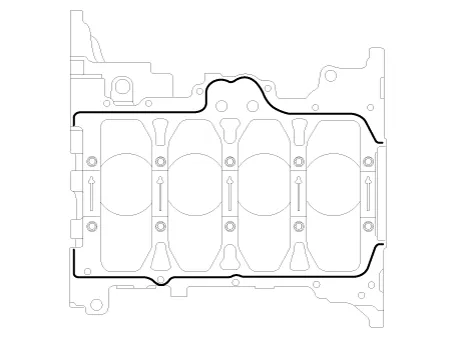

Apply liquid sealant on the top surface of the lower crankcase.

|

| 5. |

Place the lower crankcase on the cylinder block. |

| 6. |

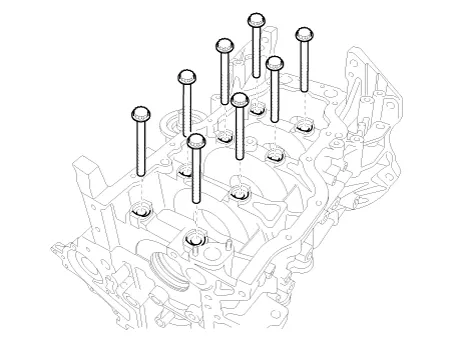

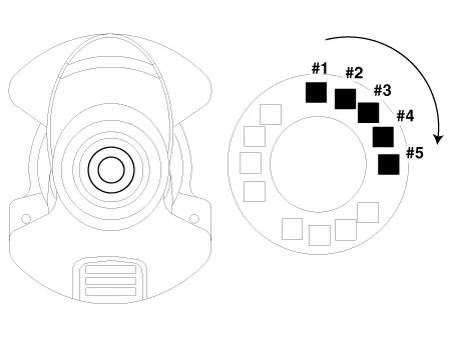

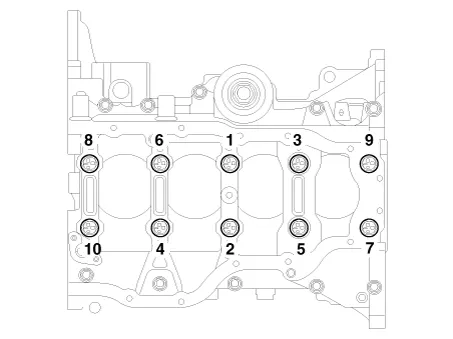

Install the main bearing cap bolts.

Using SST (09221-4A000), install and tighten the 10 main bearing cap bolts, in several passes, in the sequence as shown.

|

| 7. |

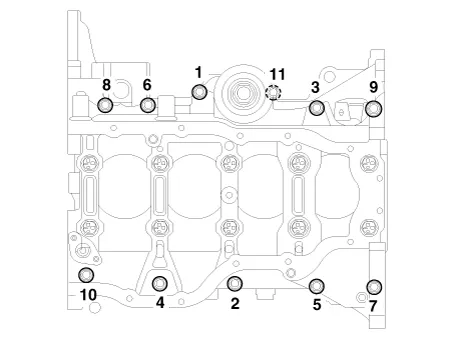

Install the lower crankcase bolts, in several passes, in sequence as shown.

Check that the crankshaft turns smoothly. |

| 8. |

Check the crankshaft end play. |

| 9. |

Assemble the other parts in the reverse order of disassembly. |

In case the crankshaft is replaced with a new one, select the proper connecting rod bearing according to the pin journal mark on the crankshaft.

|

Components and components location Components 1. Piston ring 2. Snap ring 3. Piston pin 4. Piston 5. Connecting rod 6.

Repair procedures Disassembly • Use fender covers to avoid damaging painted surfaces.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Ventilated and Heated Seat

Schematic diagrams Connector and Terminal Function Pin Function Connector A Connector B 1 Driver heater ground (-) Driver blower speed (+) 2 Passenger heater ground (-) - 3

Kia Optima DL3 2019-2026 Service and Repair Manual: Receiver-Drier

Repair procedures Replacement 1. Remove the condenser. 2. Remove the cap (A) on the bottom of the condenser with a L wrench. Tightening torque : 9.81 - 14.71 N.

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Body Electrical System

- Engine Control Module (ECM)

- Charging System

- New on site

- Most important about car