Kia Optima DL3: Air Conditioning System / Refrigerant Line

Components and components location

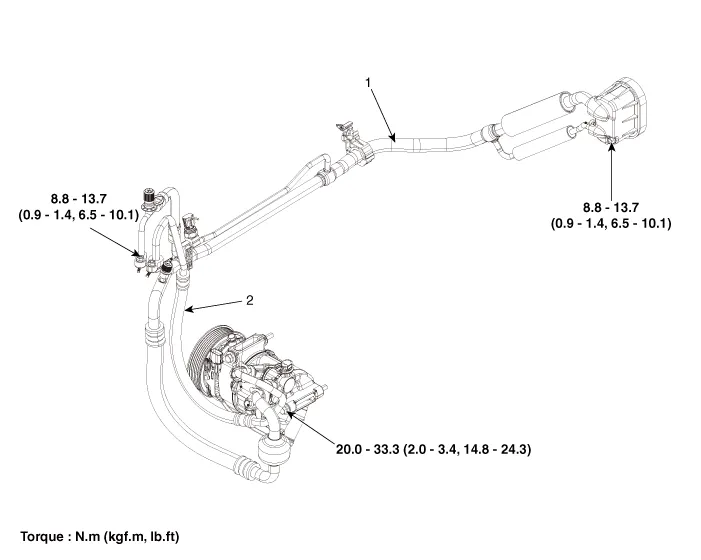

| Components Location |

| 1. Suction & Liquid tube assembly

|

2. Discharge hose |

Repair procedures

| Replacement |

| 1. |

If the compressor is marginally operable, run the engine at idle speed, and let the air conditioning work for a few minutes, then shut the engine off. |

| 2. |

Disconnect the negative (-) battery terminal. |

| 3. |

Recover the refrigerant with a recovery / charging station. |

| 4. |

Remove the engine mounting support bracket. G 2.0 NU MPI (Refer to Engine Mechanical System - "Engine Mounting") G 2.5 GDI THETA II (Refer to Engine Mechanical System - "Engine Mounting") |

| 5. |

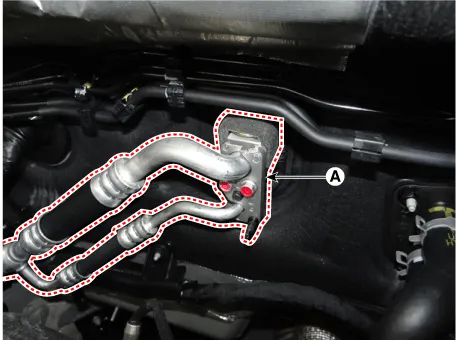

Loosen the mounting nut and remove the expansion valve cover (A).

|

| 6. |

Remove the bolts and the expansion valve (A) from the evaporator core.

|

| 7. |

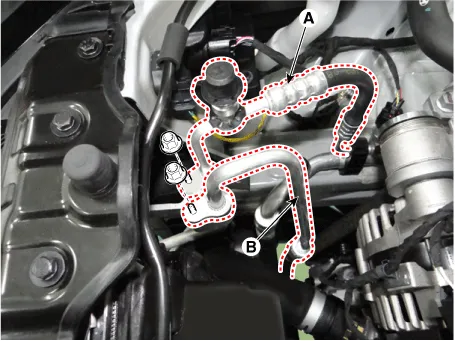

Press the lock pin and separate the A/C pressure transducer connector (A).

|

| 8. |

Loosen the mounting nuts, remove the suction line (A) and discharge line (B).

|

| 9. |

Remove the engine room under cover. G 2.0 NU MPI (Refer to Engine Mechanical System - "Engine Cover") G 2.5 GDI THETA II (Refer to Engine Mechanical System - "Engine Cover") |

| 10. |

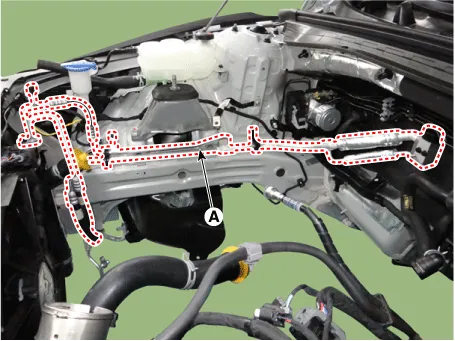

Remove the bolts, then disconnect the suction line (A) and discharge line (B) from the compressor.

|

| 11. |

Remove the suction & liquid tube assembly (A) to the upper of engine room.

|

| 12. |

To install, reverse the removal procedure.

|

Repair procedures Oil Specification 1. The HFC-134a system requires synthetic (PAG) compressor oil whereas the R-12 system requires mineral compressor oil.

Description and operation Description The compressor is the power unit of the A/C system. It is located on the side of engine block and driven by a V-belt of the engine.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Heater Unit

Components and components location Component Location 1. Heater unit assembly Compoents 1. Mode control actuator 2. Temperature control actuator [LH] 3. PTC Heater dummy 4.

Kia Optima DL3 2019-2026 Service and Repair Manual: Climate Control Air Filter

Description and operation Description The climate control air filter is located in the blower unit. It eliminates foreign materials and odor. The particle filter performs a role as an odor filter as well as a conventional dust filter to ensure comfortable interior environment.

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Lift And Support Points

- Automatic Transaxle System

- Timing Chain

- New on site

- Most important about car