Kia Optima DL3: Hydraulic System / SS-A Solenoid Valve (ON/OFF)

Specifications

Item

|

Specification

|

Control type

|

ON/OFF

|

Voltage (V)

|

9 - 16

|

Control pressure kpa (kgf/cm², psi)

|

0 - 490.33 (0 - 5.0, 0 - 71.12)

|

Coil resistance (Ω)

|

10.0 - 11.0

|

Description and operation

| • |

SS-A solenoid valve is ON/OFF type.

|

| • |

When TCM supplies variable current to solenoid valve, the solenoid valve

operates and controls the speed range.

|

SS-A Solenoid Valve

operation table

|

SS-A

|

N, P

|

●

|

1

|

Δ

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

R

|

●

|

● : Connected status

Δ : Connected at vehicle speed above 8km/h

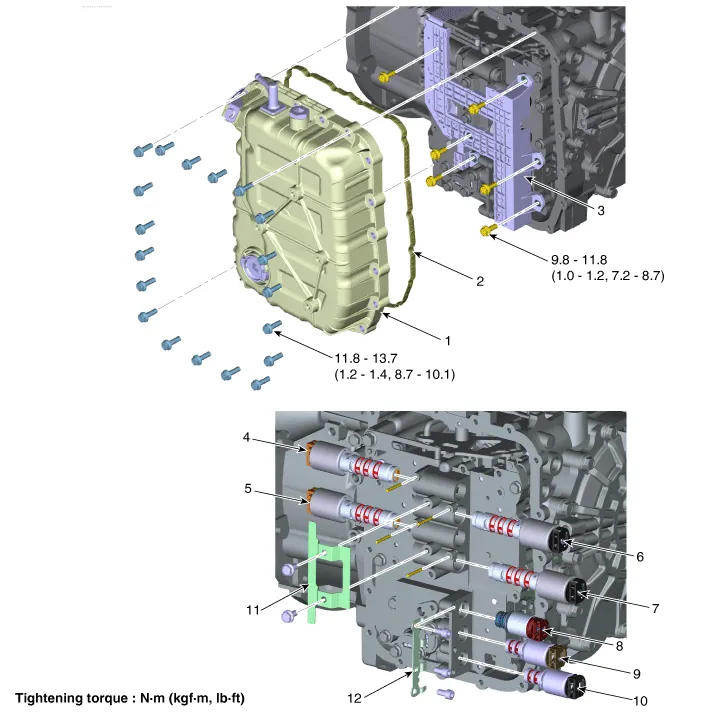

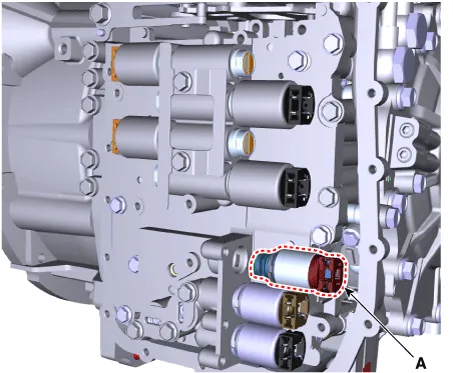

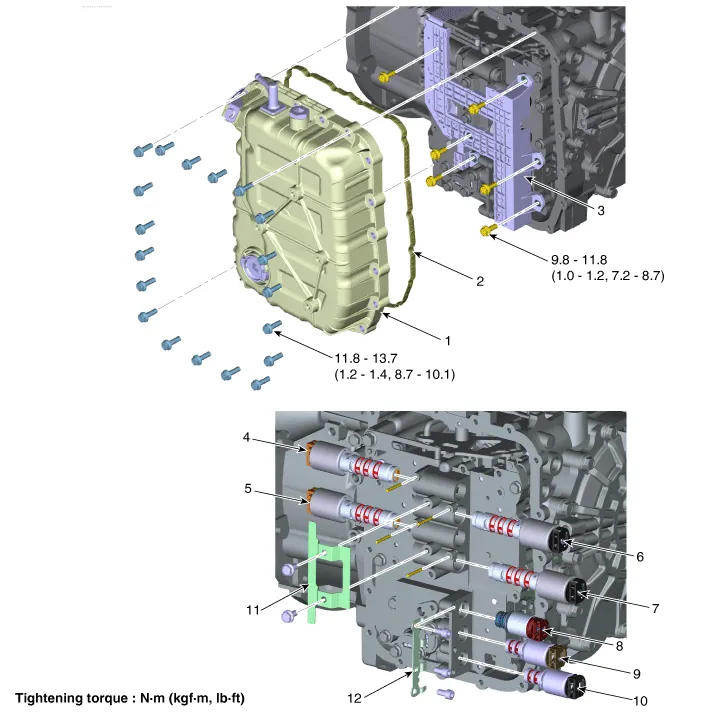

Components and components location

1. Valve Body Cover

|

8. SS-A ON/OFF Solenoid Valve

|

2. Valve Body Gasket

|

9. Torque Converter Control Solenoid

Valve

|

3. Main Harness

|

10. Line Pressure Control Solenoid

Valve

|

4. 26 Brake Control Solenoid

Valve

|

11. Support Bracket

|

5. 35R Clutch Control Solenoid

Valve

|

12. Support Bracket

|

6. Underdrive Brake Control Solenoid

Valve

|

|

7. Overdrive Clutch Control Solenoid

Valve

|

|

Repair procedures

| 1. |

The automatic transaxle system can be more quickly diagnosed for troubles

by using the vehicle diagnostic system (KDS). (Refer to "DTC guide")

KDS provides the following information.

| (1) |

Self diagnosis : Inspects and displays diagnostic trouble code

(DTC)

|

| (2) |

Sensor data : Checks the system input/output value status

|

| (3) |

Forced operation : Checks the system operating status

|

| (4) |

Additional function : Controls system options, zero point adjustment

and other functions

|

|

| 1. |

Switch "OFF" ignition.

|

| 2. |

Remove the air cleaner assembly.

(Refer to Engine Mechanical System - "Air cleaner")

|

| 3. |

Remove the battery and battery tray.

(Refer to Engine Electrical System - "Battery")

|

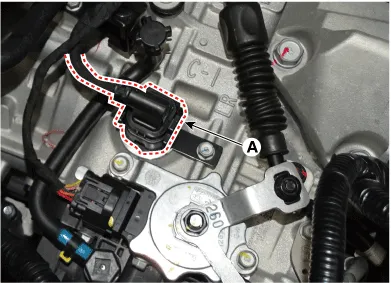

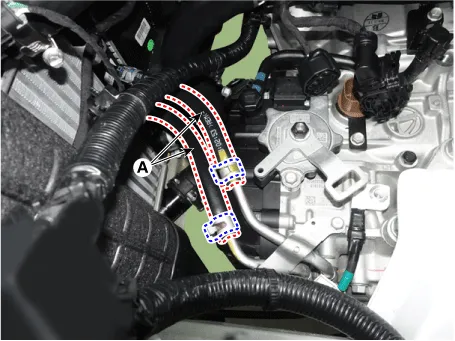

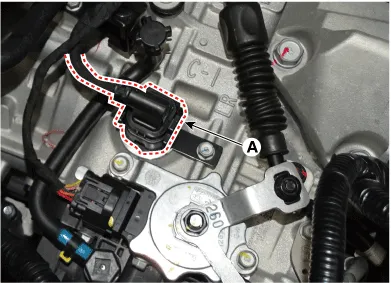

| 4. |

Disconnect the solenoid valve connector (A).

|

| 5. |

Measure the resistance between power terminal (10) and signal terminal

(18).

|

Specification : 10.0 - 11.0 Ω

|

|

| • |

Automatic transaxle is composed of delicate components. Be careful

not to cause any damage on the component in the course of assembly

and disassembly.

|

| • |

Maintain clean condition so that foreign substance does not get

into the automatic transaxle.

|

| • |

Use a coated apron, latex gloves, and stainless tray to prevent

foreign substance from getting into the transaxle.

|

|

| 1. |

Remove the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

|

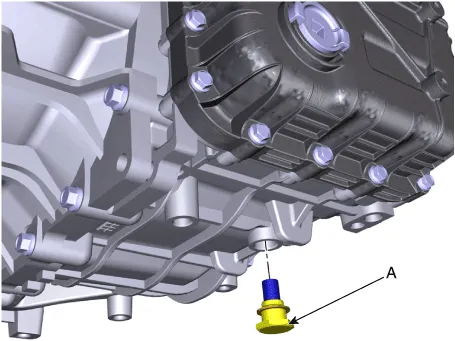

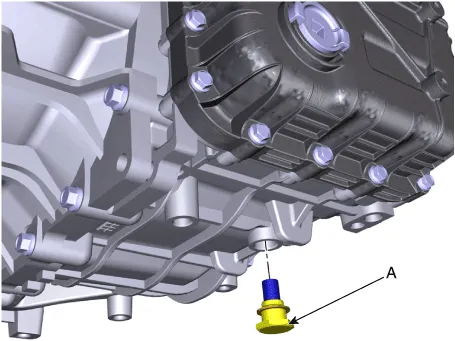

| 2. |

Remove the ATF drain plug (A), allow the fluid to drain out and then

reinstall the drain plug.

|

Tightening torque:

33.3 - 43.1 N·m (3.4 - 4.4 kgf·m, 24.6 - 31.8 lb·ft)

|

| •

|

The existing ATF drain plug gasket must be replaced with

a new one. (Do not reuse it.

|

| •

|

Automatic transaxle fluid (ATF) can be reused. Collect

it using a clean 10-liter beaker.

|

|

|

| 3. |

Remove the air duct and air cleaner assembly.

(Refer to Engine Mechanical System - "Air cleaner")

|

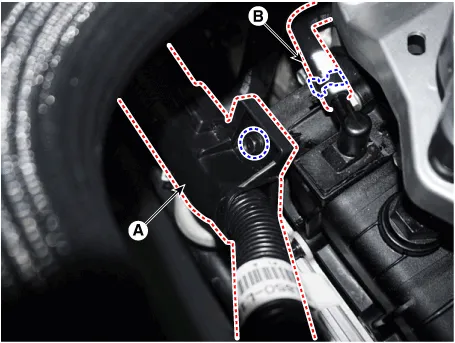

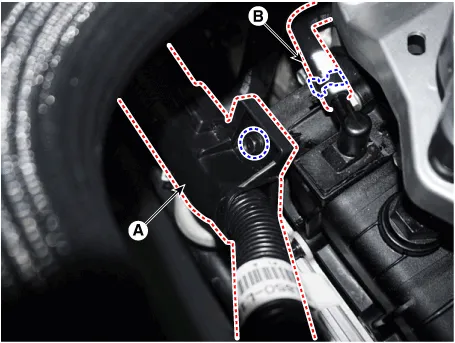

| 4. |

Remove the fixing clip (A) and the air breather hose (B).

|

Tightening torque:

9.8 - 11.8 N·m (1.0 - 1.2 kgf·m, 7.2 - 8.7 lb·ft)

|

|

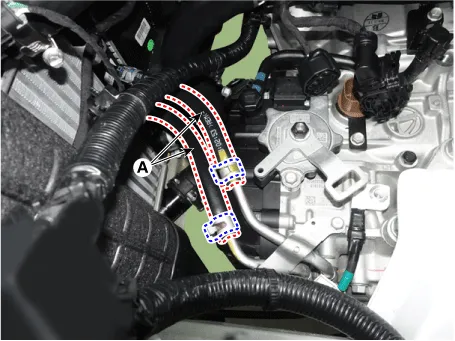

| 5. |

Separate the ATF cooler hose (A).

|

| 6. |

Lift the vehicle after loosening valve body cover upper bolts.

|

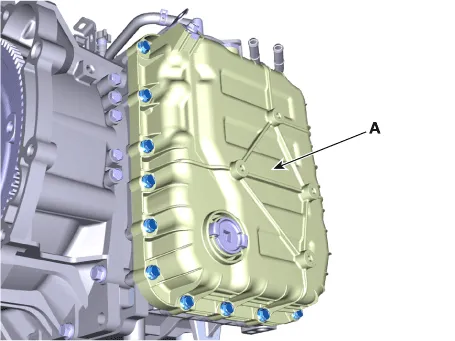

| 7. |

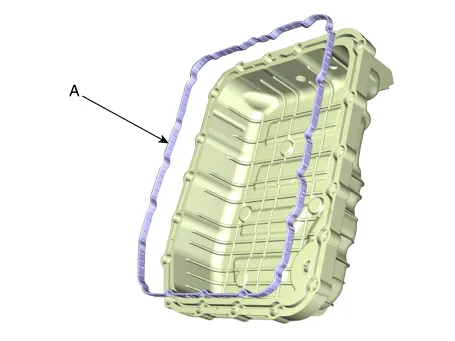

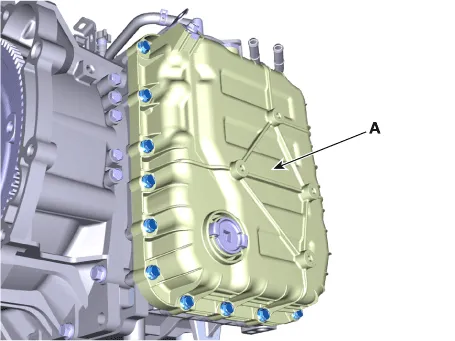

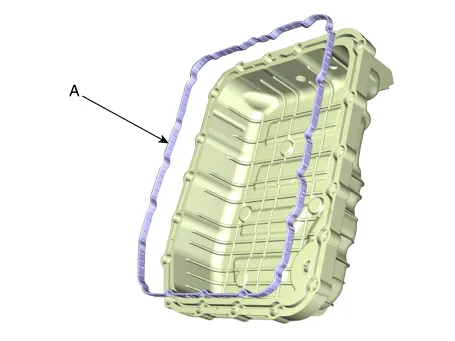

Remove the valve body cover (A) by loosening bolts.

|

Tightening torque:

11.8 - 13.7 N·m (1.2 - 1.4 kgf·m, 8.7 - 10.1 lb·ft)

|

|

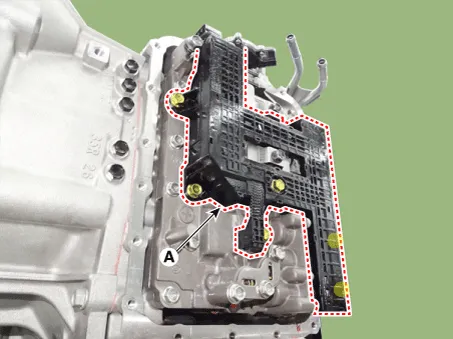

| 8. |

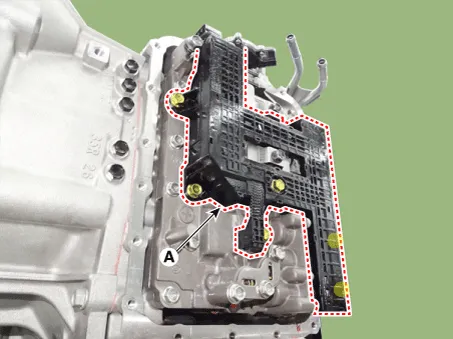

Remove the main harness (A) after removing the bolts.

|

Tightening torque:

9.8 - 11.8 N·m (1.0 - 1.2 kgf·m, 7.2 - 8.7 lb·ft)

|

|

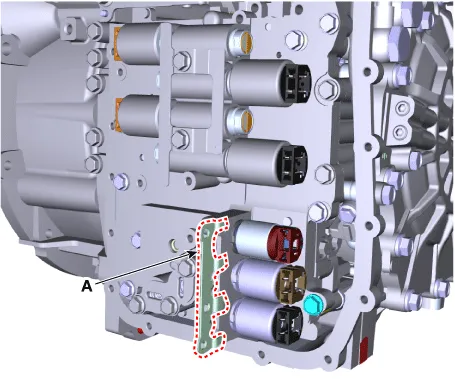

| 9. |

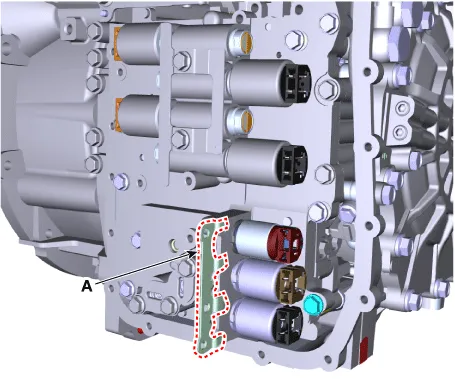

Remove solenoid valve support bracket (A) after loosening the bolts.

|

Tightening torque:

9.8 - 11.8 N·m (1.0 - 1.2 kgf·m, 7.2 - 8.7 lb·ft)

|

|

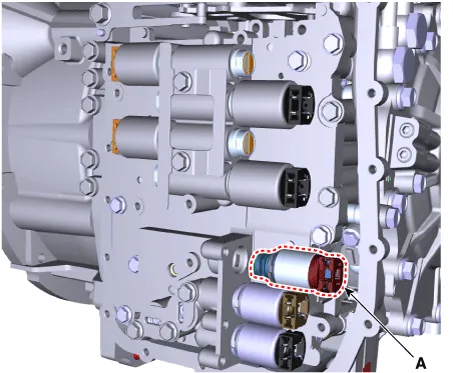

| 10. |

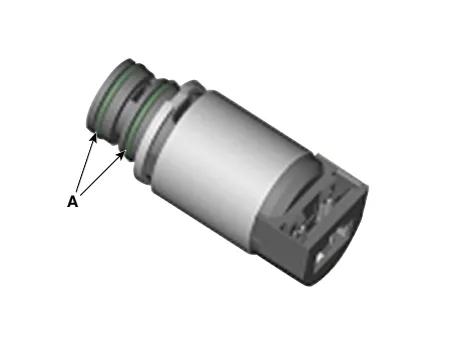

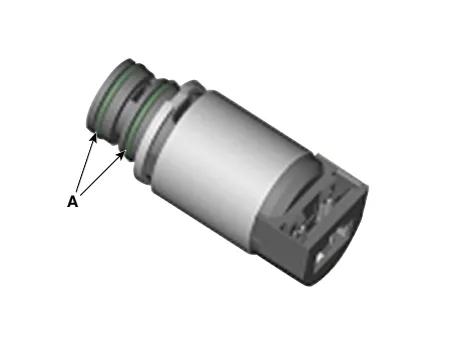

Remove the SS-A solenoid valve (A).

|

| 1. |

Install in the reverse order of removal.

| •

|

When installing, apply the ATF oil or petroleum jelly

to the O-rings (A) to prevent damage.

|

| •

|

The existing valve body cover gasket (A) must be replaced

with a new one. (Do not reuse it.)

|

|

|

| 2. |

Perform the procedures below after installing.

| (1) |

Refill the automatic transaxle with fluid.

(Refer to Hydraulic System - "Fluid")

|

| (2) |

Clear the diagnostic trouble codes (DTC) using the KDS. Disconnecting

the battery negative terminal will not clear the DTCs. Clear DTCs

using the KDS at all times.

|

| (3) |

Check for leakage of coolant or fluid from hose connection during

engine start.

|

|

Specifications

Specification

Item

Specification

Control type

N/H (Normal High)

Control pressure (kpa (kgf/cm², psi))

0 - 519.

Tightening torque

Tightening Torque

Item

N·m

kgf·m

lb·ft

Front

Tire wheel hub nut

107.

Other information:

Service data

Service Data

Air Conditioner

ltem

Specification

Compressor

Type

6SAS14

Oil type & Capacity

ND-OIL 12 80 ± 10 cc (2.82 ± 0.

Description and operation

Description

The In-car air temperature sensor is built in the heater & A/C control unit.

The sensor contains a thermistor which measures the temperature of the inside.

The signal decided by the resistance value which changes in accordance with perceived

inside temperature, is delivered to heater co