Kia Optima DL3: Brake System / Brake Booster

Components and components location

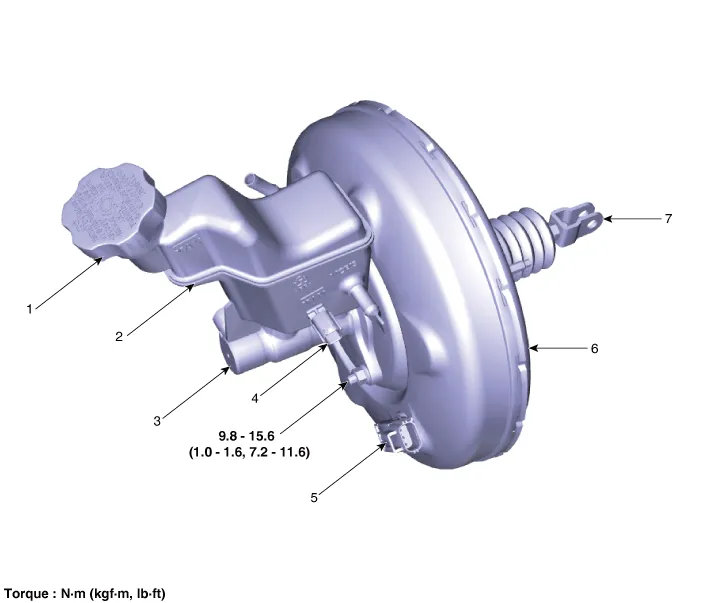

| Components |

| 1. Reservoir cap 2. Reservoir 3. Master cylinder 4. Brake fluid level sensor |

5. Vacuum sensor 6. Brake booster 7. Push rod |

Repair procedures

| Brake Booster Operation Test |

For simple checking of the brake booster operation, perform the following tests.

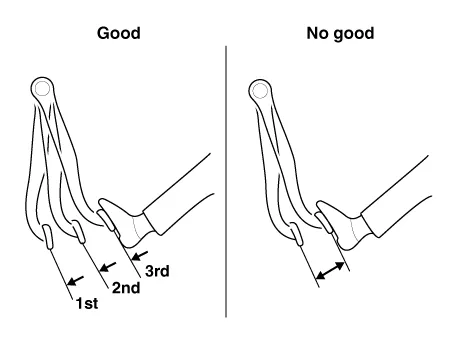

| 1. |

Run the engine for one to two minutes, and then stop it. If the pedal depresses fully initially but gradually becomes higher in the successive attempts, the booster is operating properly. If the pedal height remains unchanged, the booster is inoperative.

|

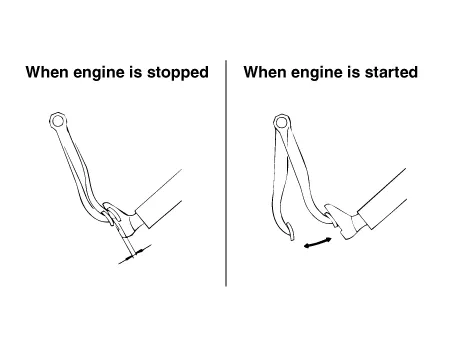

| 2. |

With the engine stopped, step on the brake pedal several times. Then step on the brake pedal and start the engine. If the pedal moves downward slightly, the booster is in good condition. If there is no change, the booster is inoperative.

|

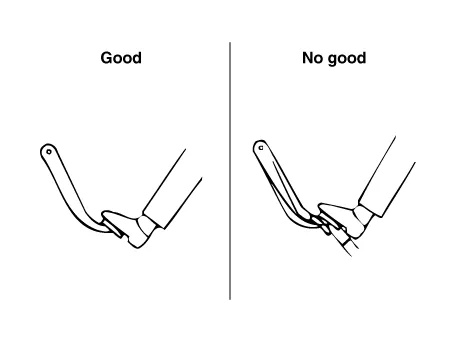

| 3. |

With the engine running, step on the brake pedal and then stop the engine. Hold the pedal depressed for 30 seconds. If the pedal height does not change, the booster is in good condition, and if the pedal rises, the booster is inoperative. If the three tests above are met,, the booster performance can be considered as in good condition. Even if one of the three test above are unsatisfactory, check the check valve, vacuum hose and booster for malfunction.

|

| Removal |

| 1. |

Turn ignition switch OFF and disconnect the negative (-) battery cable. |

| 2. |

Remove the air cleaner assembly. G 2.0 NU MPI (Refer to Engine Mechanical System - "Air Cleaner") G 2.5 GDI THETA II (Refer to Engine Mechanical System - "Air Cleaner") |

| 3. |

Remove the battery. G 2.0 NU MPI (Refer to Engine Electrical System - "Battery") G 2.5 GDI THETA II (Refer to Engine Electrical System - "Battery") |

| 4. |

Remove the ECM bracket assembly. G 2.0 NU MPI (Refer to Engine Control / Fuel System - "Engine Control Module (ECM)") G 2.5 GDI THETA II (Refer to Engine Control / Fuel System - "Engine Control Module (ECM)") |

| 5. |

Remove the Master Cylinder. (Refer to Brake System - "Master Cylinder") |

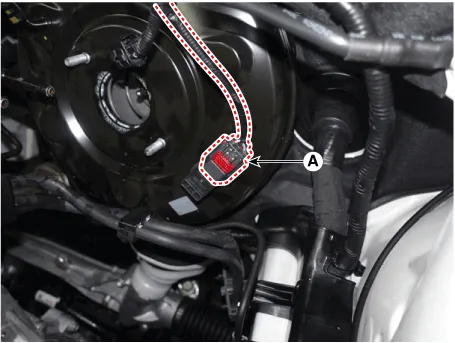

| 6. |

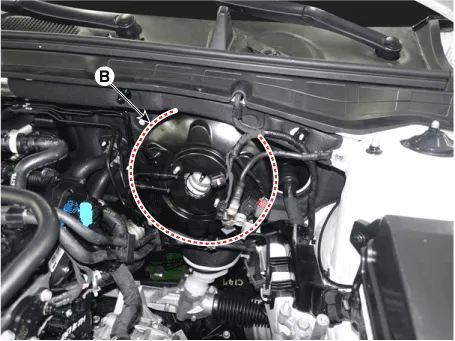

Disconnect the brake booster vacuum pressure sensor connector (A).

|

| 7. |

Remove the fixing clip and the vacuum hose (A) from the brake booster.

|

| 8. |

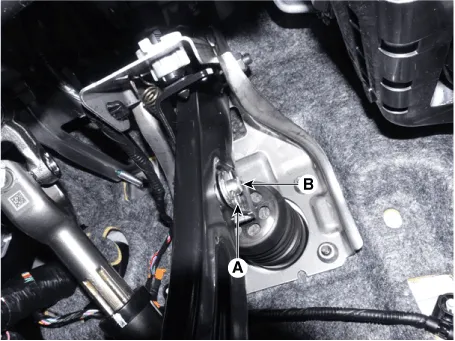

Remove the snap pin (A) and the clevis pin (B).

|

| 9. |

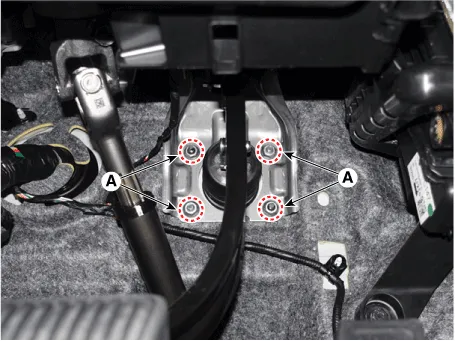

Loosen the fixed nut (A) and then removing the brake booster (B).

|

| Inspection |

| 1. |

Inspect the vacuum hose. |

| 2. |

Check the boot for damage. |

| Installation |

| 1. |

Install in the reverse order of removal.

|

| 2. |

After installation, bleed the brake system. (Refer to Brake System - "Brake Bleeding Prcoedures") |

| 3. |

Check the brake oil leakage and pedal operating condition. |

Repair procedures Operation and Leakage Check Check all of the following items: Component Procedure Brake Booster (A) Check brake operation by applying the brakes during a test drive.

Components and components location Components 1. Reservoir cap 2. Reservoir 3. Master cylinder 4. Brake fluid level sensor Repair procedures Removal 1.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Integrated Memory Seat (IMS) Unit

Specifications Specifications Item Specifications Rated voltage DC 12 V Operating voltage DC 9 - 16 V Operating temperature range -22 to 167°F (-30 to 75°C) Dark current Max.

Kia Optima DL3 2019-2026 Service and Repair Manual: Power Door Mirror Actuator

Schematic diagrams Connector and Terminal Function Repair procedures Inspection 1. Disconnect the negative battery terminal. 2. Remove the front door trim. (Refer to Body - "Front Door Trim") 3.

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Automatic Transaxle System

- Lift And Support Points

- Floor Console Assembly

- New on site

- Most important about car