Kia Optima DL3: Power Train / Drive Belt

Repair procedures

| Inspection |

| 1. |

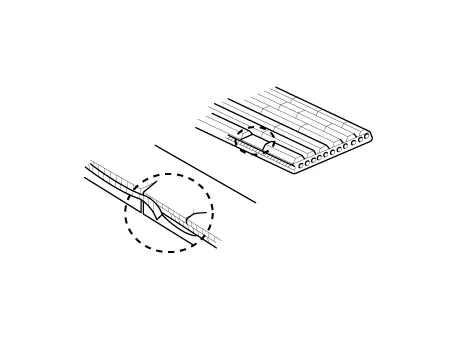

Check belt for maintenance and abnormal wear of V-ribbed part. Replace if necessary.

|

| 2. |

Visually check the belt for excessive wear, frayed cords etc. If any defect has been found, replace the drive belt.

|

| Removal and Installation |

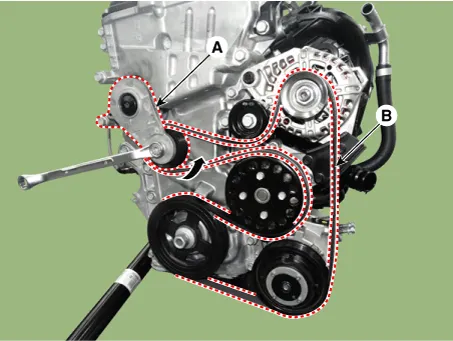

| [NU 2.0 MPI] |

| 1. |

Remove the engine room under cover. (Refer to Engine and Transaxle Assembly - "Engine Room Under Cover") |

| 2. |

Using the wrench, turning the auto tensioner pulley (A) counterclockwise and then remove the drive belt (B).

|

| 3. |

Install in the reverse order of removal. |

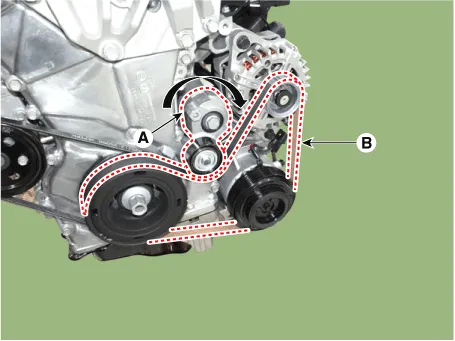

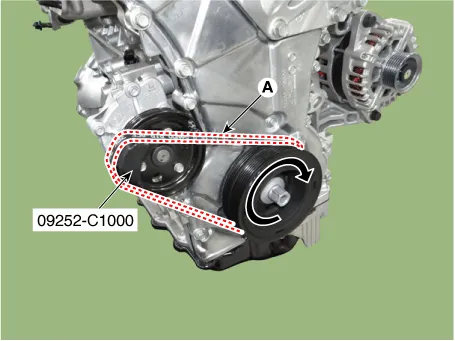

[THETAIII 2.5 GDI]

| 1. |

Remove the engine room under cover. (Refer to Engine and Transaxle Assembly - "Engine Room Under Cover") |

| 2. |

For release the tension, turn the drive belt tensioner (A) clockwise then remove the drive belt (B).

|

| 3. |

Remove the water pump belt.

|

| Installation |

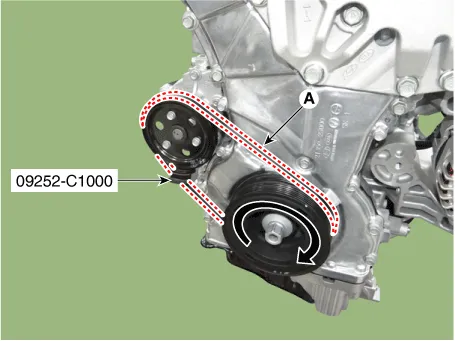

[THETAIII 2.5 GDI]

| 1. |

Install the water pump belt.

|

| 2. |

For release the tension, turn the drive belt tensioner (A) clockwise then install the drive belt (B).

|

| 3. |

Install in the reverse order of removal. |

Repair procedures Inspection Radiator hoses 1. Check radiator hoses for the following: (1) Improper attachment (2) Leaks (3) Cracks (4) Damage (5) Loose connections (6) Chafing (7) Deterioration Coolant level 1.

Repair procedures Inspection 1. Check the engine oil quality. Check the oil deterioration, entry of water, discoloring of thinning.

Other information:

Kia Optima DL3 2019-2025 Service and Repair Manual: Panorama Sunroof

C

Kia Optima DL3 2019-2025 Service and Repair Manual: Power Mosfet

Description and operation Description It is installed to the DATC and adjusts the fan rpm by precisely controlling the voltage applied to the blower motor. Repair procedures Inspection 1. Turn the ignition switch ON.

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Engine Control / Fuel System

- Engine Control Module (ECM)

- Suspension System

- New on site

- Most important about car