Kia Optima DL3: Engine Control System / ETC (Electronic Throttle Control) System

Specifications

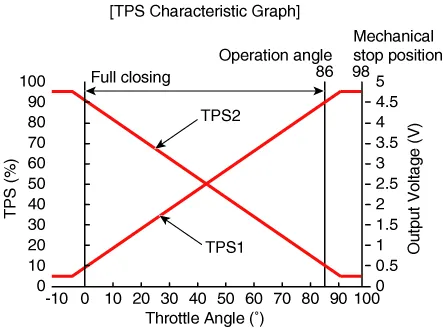

| Specification |

|

Throttle angle (°) |

Output voltage (V) [Vref = 5.0V] |

|

|

TPS1 |

TPS2 |

|

|

0 |

0.5 |

4.5 |

|

10 |

0.96 |

4.05 |

|

20 |

1.41 |

3.59 |

|

30 |

1.87 |

3.14 |

|

40 |

2.32 |

2.68 |

|

50 |

2.78 |

2.23 |

|

60 |

3.23 |

1.77 |

|

70 |

3.69 |

1.32 |

|

80 |

4.14 |

0.86 |

|

90 |

4.6 |

0.41 |

|

98 |

4.65 |

0.35 |

|

C.T (0) |

0.5 |

4.5 |

|

W.O.T (86) |

4.41 |

0.59 |

[ETC Motor]

|

Item |

Specification |

|

Coil Resistance (Ω) |

0.3 - 100 [20°C(68°F)] |

Description and operation

| Description |

| • |

The Electronic Throttle Control (ETC) System consists of a throttle body with an integrated control motor and Throttle Position Sensor (TPS). |

| • |

Instead of the traditional throttle cable, an Accelerator Position Sensor (APS) is used to receive driver input. |

| • |

The ECM uses the APS signal to calculate the target throttle angle; the position of the throttle is then adjusted via ECM control of the ETC motor. |

| • |

The TPS signal is used to provide feedback regarding throttle position to the ECM. |

| • |

Using ETC, precise control over throttle position is possible; the need for external cruise control modules/cables is eliminated. |

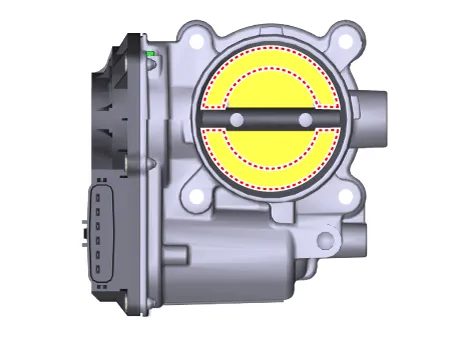

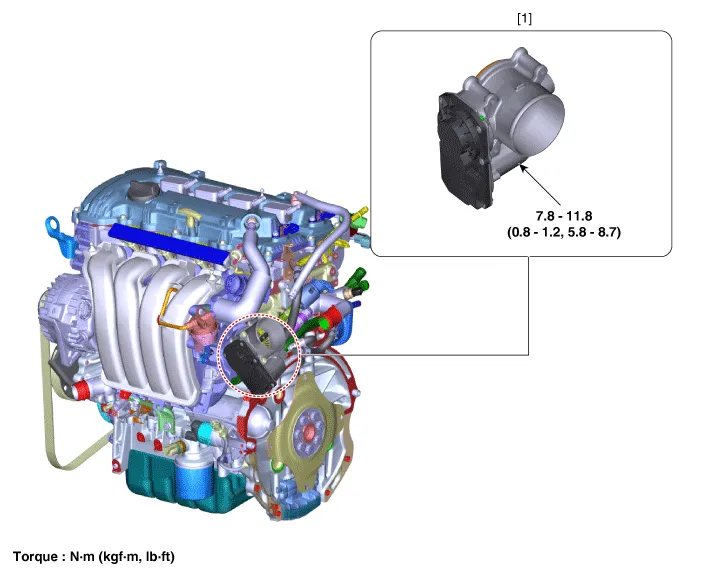

Components and components location

| Components Location |

| 1. ETC (Electronic Throttle Control)

|

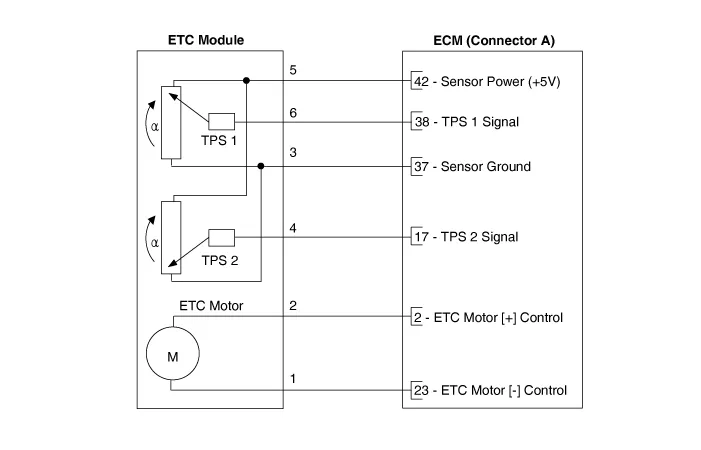

Schematic diagrams

| Circuit Diagram |

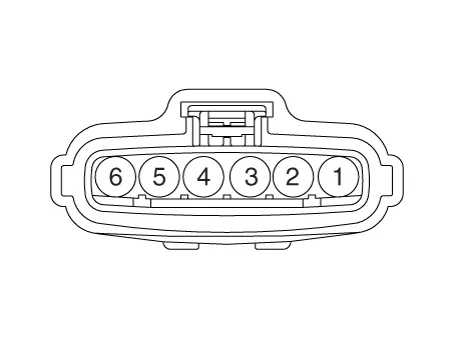

Harness Connector

Repair procedures

| Inspection |

| 1. |

The engine control system can be more quickly diagnosed for troubles by using the vehicle diagnostic system (KDS). (Refer to "DTC guide") KDS provides the following information.

|

Throttle Position Sensor (TPS)

| 1. |

Connect the KDS on the Data Link Connector (DLC). |

| 2. |

Start the engine and measure the output voltage of TPS 1 and 2 at C.T. and W.O.T.

|

||||||||||||||||||||||||||||||||||||||||||||

ETC Motor

| 1. |

Disconnect the ETC module connector. |

| 2. |

Measure resistance between the ETC module terminals 1 and 2.

|

| Removal |

| 1. |

Disconnect the negative battery terminal. |

| 2. |

Remove the air cleaner. (Refer to Engine Mechanical System - "Air Cleaner") |

| 3. |

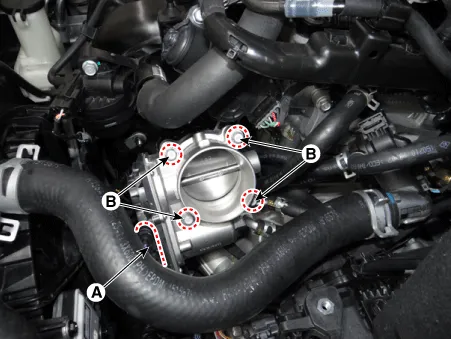

After disconnecting the connector (A), remove the ETC module by loosening the bolts (B).

|

| 4. |

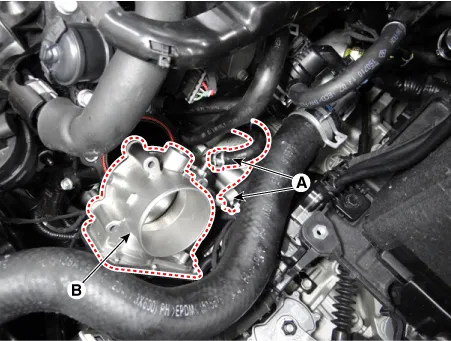

Separate the coolant hoses (A) from the ETC module (B).

|

| Installation |

|

| 1. |

Install in the reverse order of removal. |

| 2. |

Supplement the engine coolant. (Refer to Engine Mechanical System - "Coolant") |

| 3. |

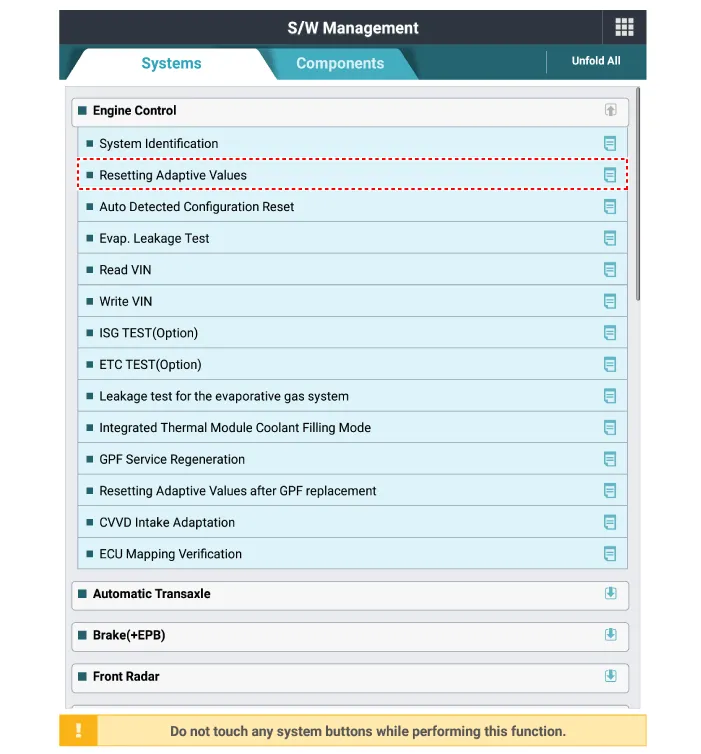

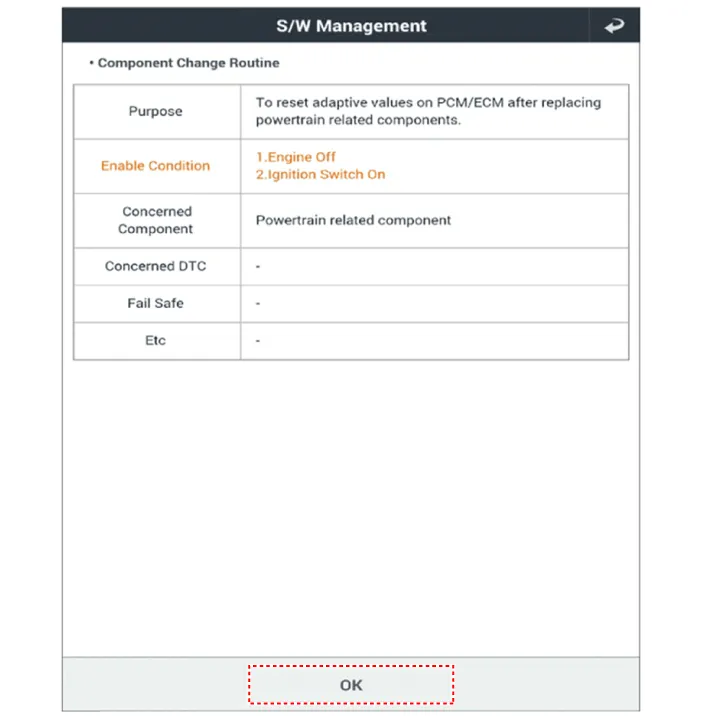

Reset the ECM adaptive values after replacing the ETC.

|

| 4. |

Perform the ETC learning procedure. (Refer to ETC (Electronic Throttle Control) System - "Adjustment") |

| Adjustment |

|

| 1. |

Wait for 1 minute with the ignition switch ON. |

| 2. |

Start the engine and hold the idle status for 15 minutes. |

| 3. |

Waif for 1 minute with the ignition switch OFF. |

| 4. |

Restart the engine, check that the idle speed is stable. |

| Cleaning |

| 1. |

Remove the ETC. (Refer to ETC - "Removal")

|

| 2. |

Clean the pollutant in the throttle body using a soft cloth moistened with cleaning fluid.

|

| 3. |

Install the ETC. (Refer to ETC - "Installation") |

| 4. |

Reset the ETC adaptive value.

|

| 5. |

Perform the ETC learning procedure. (Refer to ETC - "Adjustment") |

Troubleshooting

| Fail-Safe Mode |

|

Item |

Fail-Safe |

|

|

ETC Motor |

Throttle valve stuck at 7° |

|

|

TPS |

TPS 1 fault |

Replace it with TPS 2 |

|

TPS 2 fault |

Replace it with TPS 1 |

|

|

TPS 1,2 fault |

Throttle valve stuck at 7° |

|

|

APS |

APS 1 fault |

Replace it with APS 2 |

|

APS 2 fault |

Replace it with APS 1 |

|

|

APS 1,2 fault |

Engine idle state |

|

When throttle value is stuck at 7°, engine speed is limited at below 1,500rpm and vehicle speed at maximum 40 - 50 km/h (25 - 31 mph) |

Components and components location Component Location 1. Engine Control Module (ECM) Schematic diagrams Connector and Terminal function ECM Terminal Function [Connector A] Pin Function Connected to 1 - 2 ETC Motor [+] control output ETC Motor 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 Sensor ground Engine Coolant Temperature Sensor (ECTS) 16 Engine Coolant Temperature Sensor (ECTS) signal input Engine Coolant Temperature Sensor (ECTS) 17 Throttle Position Sensor (TPS) 2 signal input Throttle Position Sensor (TPS) 2 [ETC Module] 18 - 19 - 20 - 21 Sensor power (+5V) Manifold Absolute Pressure Sensor (MAPS) Camshaft Position Sensor (CMPS) [Bank 1 / Intake] 22 - 23 ETC Motor [-] control output ETC Motor [ETC Module] 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 Electrical load signal input (FR) Alternator 32 - 33 - 34 - 35 - 36 - 37 Sensor ground Throttle Position Sensor (TPS) 1, 2 [ETC Module] 38 Throttle Position Sensor (TPS) 1 signal input Throttle Position Sensor (TPS) 1 [ETC Module] 39 - 40 Alternator PWM control output Alternator 41 - 42 Sensor power (+5V) Throttle Position Sensor (TPS) 1, 2 [ETC Module] 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 Sensor ground Camshaft Position Sensor (CMPS) [Bank 1/Exhaust] 57 - 58 - 59 - 60 - 61 Sensor ground Manifold Absolute Pressure Sensor (MAPS) 62 Manifold Absolute Pressure Sensor (MAPS) signal input Manifold Absolute Pressure Sensor (MAPS) 63 Sensor power (+5V) Camshaft Position Sensor (CMPS) [Bank 1 / Exhaust] 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74 Sensor ground Crankshaft Position Sensor (CKPS) 75 - 76 - 77 Camshaft Position Sensor (CMPS) [Bank 1 / Exhaust] signal input Camshaft Position Sensor (CMPS) [Bank 1 / Exhaust] 78 Sensor ground Camshaft Position Sensor (CMPS) [Bank 1 / Intake] 79 - 80 - 81 - 82 - 83 VG (Virtual Ground) Heated Oxygen Sensor [Bank 1 / Sensor 1] 84 VRC (Current Adjust) Heated Oxygen Sensor [Bank 1 / Sensor 1] 85 - 86 - 87 - 88 - 89 - 90 - 91 - 92 - 93 - 94 - 95 Crankshaft Position Sensor (CKPS) signal input Crankshaft Position Sensor (CKPS) 96 - 97 - 98 Camshaft Position Sensor (CMPS) [Bank 1 / Intake] signal input Camshaft Position Sensor (CMPS) [Bank 1 / Intake] 99 Sensor ground Knock Sensor (KS) 100 Knock Sensor (KS) signal input Knock Sensor (KS) 101 Intake Air Temperature Sensor (IATS) signal input Intake Air Temperature Sensor (IATS) 102 - 103 - 104 VN (NERNST Cell Voltage) Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 1] 105 VIP (Current Pump) Heated Oxygen Sensor [Bank 1 / Sensor 1] [Connector B] Pin Function Connected to 1 Power ground Chassis Ground 2 Power ground Chassis Ground 3 Battery power (B+) Main Relay 4 Power ground Chassis Ground 5 Battery power (B+) Main Relay 6 Battery power (B+) Main Relay 7 - 8 - 9 - 10 Accelerator Position Sensor (APS) 2 signal input Accelerator Position Sensor (APS) 2 11 A/C Pressure Transducer (APT) signal input A/C Pressure Transducer (APT) 12 - 13 - 14 Sensor power (+5V) A/C Pressure Transducer (APT) 15 - 16 Sensor power (+5V) Accelerator Position Sensor (APS) 2 17 Sensor power (+5V) Accelerator Position Sensor (APS) 1 18 Main Relay control output Main Relay 19 Fuel Pump Relay control output Fuel Pump Relay 20 - 21 - 22 Injector (Cylinder #2) control output Injector (Cylinder #3) 23 Injector (Cylinder #3) control output Injector (Cylinder #3) 24 - 25 - 26 - 27 Accelerator Position Sensor (APS) 1 signal input Accelerator Position Sensor (APS) 1 28 Sensor ground Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 2] 29 Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 2] signal input Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 2] 30 - 31 - 32 - 33 - 34 Start Motor relay control output Start Motor relay 35 CVVT Oil Control (OCV) Valve [Bank 1 / Exhaust] control output CVVT Oil Control Valve (OCV) [Bank 1 / Exhaust] 36 CVVT Oil Control (OCV) Valve [Bank 1 / Intake] control output CVVT Oil Control Valve (OCV) [Bank 1 / Intake] 37 - 38 A/C Relay control output A/C Relay 39 Injector (Cylinder #4) control output Injector (Cylinder #3) 40 Ignition Coil (Cylinder #2) control output Ignition Coil (Cylinder #2) 41 Battery power (B+) Ignition Switch 42 - 43 - 44 - 45 Sensor ground Accelerator Position Sensor (APS) 1 46 Sensor ground Accelerator Position Sensor (APS) 2 47 - 48 - 49 - 50 Sensor ground A/C Pressure Transducer (APT) 51 - 52 - 53 - 54 - 55 - 56 Injector (Cylinder #1) control output Injector (Cylinder #1) 57 Ignition Coil (Cylinder #4) control output Ignition Coil (Cylinder #4) 58 - 59 LOCAL-CAN [Low] Other control module, Data Link Connector (DLC) 60 P-CAN [Low] Other control module, Data Link Connector (DLC) 61 Fuel Tank Level Sensor signal input Fuel Tank Level Sensor (FLS) 62 - 63 - 64 - 65 Brake Light Switch signal input Brake Switch 66 Start signal input Ignition Switch 67 Engine speed signal output Power Distribution Module (PDM) 68 Immobilizer communication line Immobilizer control module 69 - 70 - 71 Purge Control Solenoid Valve (PCSV) control output Purge Control Solenoid Valve (PCSV) 72 - 73 Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 1] Heater control output Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 1] 74 Ignition Coil (Cylinder #3) control output Ignition Coil (Cylinder #3) 75 Memory power (B+) Engine Room Fuse & Relay Box (EMS ECU) 76 LOCAL-CAN [High] Other control module, Data Link Connector (DLC) 77 C-CAN [High] Other control module, Data Link Connector (DLC) 78 - 79 Vehicle speed signal input ABS/ESC Control Unit 80 - 81 Wiper Switch Input Signal Integrated Body Control Unit (IBU) 82 - 83 Brake Test Switch signal input Brake Switch 84 - 85 - 86 Cooling Fan Relay control output Cooling Fan Relay 87 - 88 Variable Intake Solenoid (VIS) Valve control output Variable Intake Solenoid (VIS) Valve 89 - 90 Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 2] Heater control output Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 2] 91 Ignition Coil (Cylinder #1) control output Ignition Coil (Cylinder #1) [NON-Immobilizer type] Repair procedures Inspection 1.

Specifications Specification Manifold Absolute Pressure Sensor (MAPS) Pressure Output Voltage (V) kPa kgf/cm² psi 20 0.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Power Door Mirror Actuator

Schematic diagrams Connector and Terminal Function Repair procedures Inspection 1. Disconnect the negative battery terminal. 2. Remove the front door trim. (Refer to Body - "Front Door Trim") 3.

Kia Optima DL3 2019-2026 Service and Repair Manual: Heater Core

Repair procedures Replacement 1. Disconnect the negative (-) battery terminal. 2. Remove the heater and blower assembly. (Refer to Heater - "Heater Unit") 3. Loosen the mounting screws and remove the heater core cover (A).

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Charging System

- Automatic Transaxle System

- Body Electrical System

- New on site

- Most important about car