Kia Optima DL3: Hydraulic System / Oil Pump

Repair procedures

| Removal |

If ATF is leaking due to damage on O-ring, replace O-ring with a new one. (Refer to Oil Pump - "Replacement")

|

| Oil Pump Assembly |

| 1. |

Remove the automatic transaxle assembly. (Refer to Automatic Transaxle System - "Automatic Transaxle") |

| 2. |

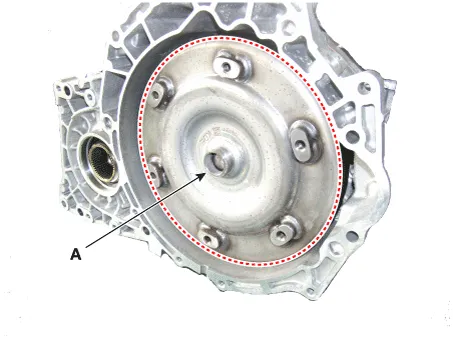

Remove the torque converter (A).

|

| 3. |

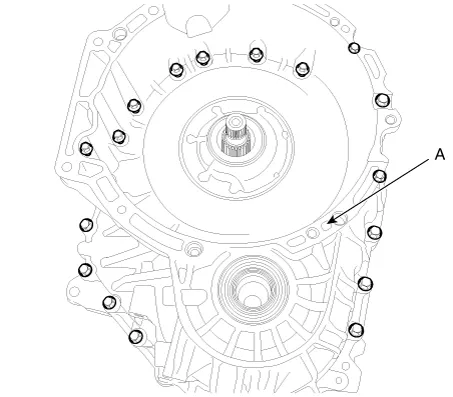

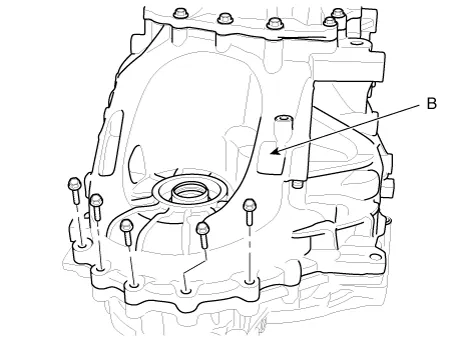

Remove the converter housing (A) from the transaxle case (B).

|

| 4. |

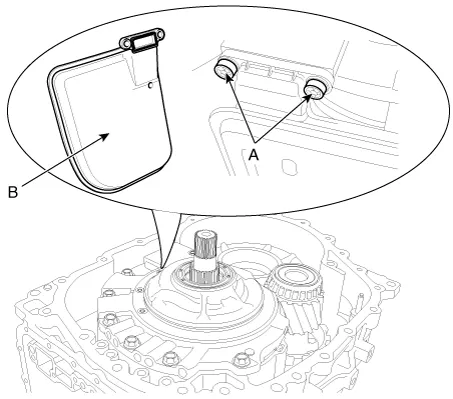

Remove the oil filter (B) after loosening the bolts (A).

|

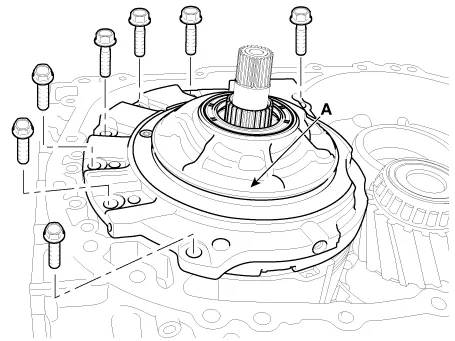

| 5. |

Remove the oil pump (A) by loosening the bolts.

|

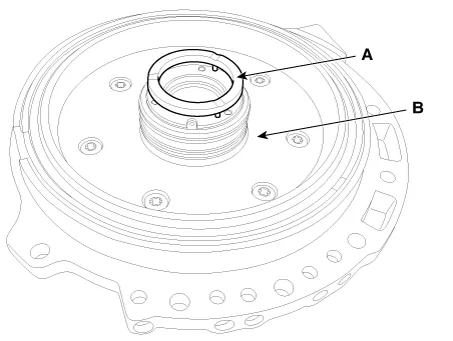

| 6. |

Remove the thrust washer (A) from the oil pump (B).

|

| Installation |

| 1. |

Assemble the thrust washer (A) to the oil pump assembly (B).

|

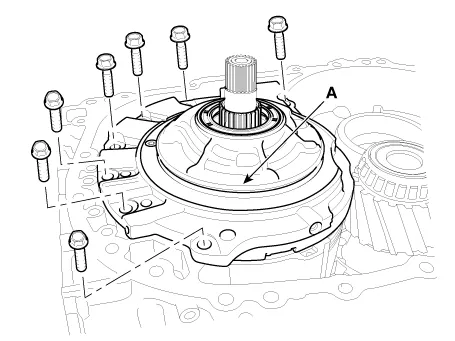

| 2. |

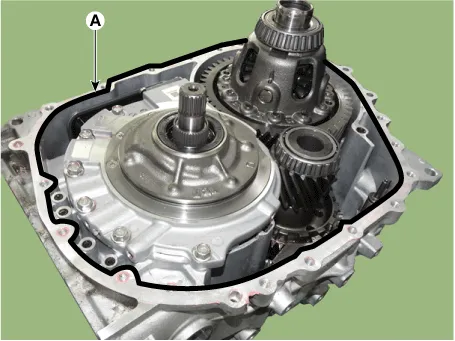

Install the oil pump assembly (A).

|

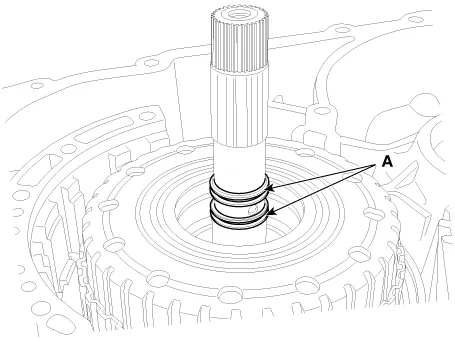

| 3. |

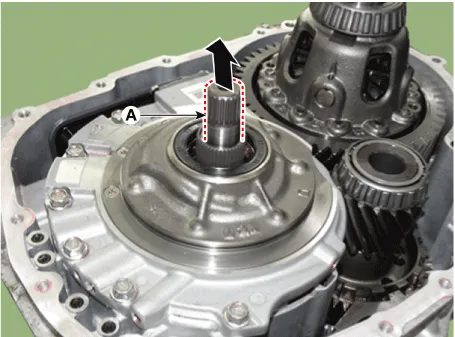

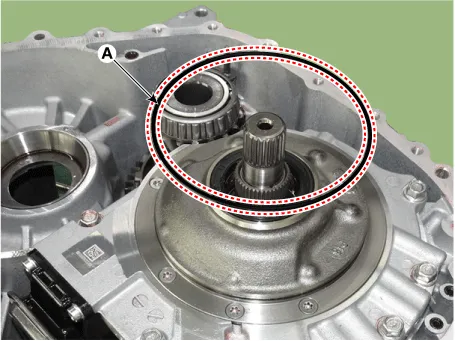

After tighten the oil pump mounting bolts, check if the movement of input shaft is 0.55 - 0.85 mm (0.0217 - 0.03346457 in.) by pulling the spline (A) to upward direction.

|

| 4. |

Install the oil filter (A).

|

| 5. |

Apply the sealant (A) on the transaxle case surface.

|

| 6. |

Install the converter housing (A) on the transaxle case (B).

|

| 7. |

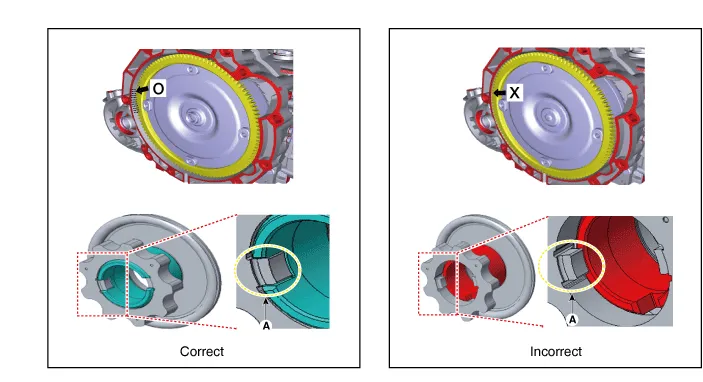

Install the torque converter (A).

|

| 8. |

Install the automatic transaxle assembly. (Refer to Automatic Transaxle System - "Automatic Transaxle") |

| Replacement |

| O-Ring |

| 1. |

Remove the automatic transaxle assembly. (Refer to Automatic Transaxle System - "Automatic Transaxle") |

| 2. |

Remove the torque converter.

|

| 3. |

Remove the clutch housing (A) from the transaxle case (B).

|

| 4. |

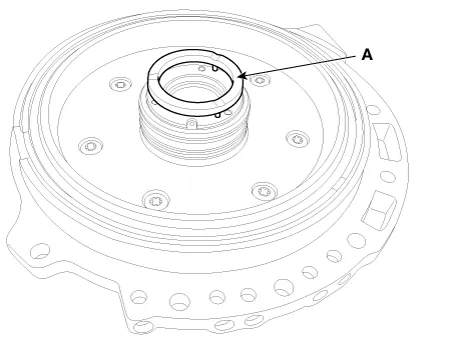

Replace the O-ring (A) with a new one.

|

| 5. |

Apply the sealant (A) on the transaxle case surface.

|

| 6. |

Install the converter housing (A) on the transaxle case (B).

|

| 7. |

Install the torque converter (A).

|

| 8. |

Install the automatic transaxle assembly. (Refer to Automatic Transaxle System - "Automatic Transaxle") |

Repair procedures Replacement It is not recommended to replace the valve body .

Specifications Specification Control type N/L (Normal Low) Control pressure kpa (kgf/cm², psi) 0 - 519.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Rear Glass Defogger

C

Kia Optima DL3 2019-2026 Service and Repair Manual: Air Conditioning System

General safety information and caution Instructions (R-134a) When Handling Refrigerant 1. R-134a liquid refrigerant is highly volatile. A drop on the skin of your hand could result in localized frostbite. When handling the refrigerant, be sure to wear gloves.

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Engine Control Module (ECM)

- Engine Mechanical System

- Suspension System

- New on site

- Most important about car