Kia Optima DL3: Body Electrical System / Power Door Mirrors

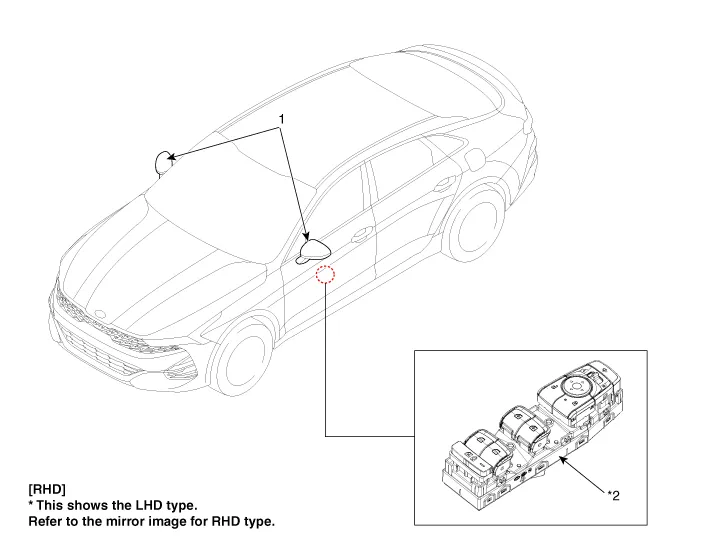

Components and components location

| Component Location |

| 1. Power door mirror |

2. Power door mirror switch

|

Repair procedures Inspection When prying with a flat-tip screwdriver or use a prying trim tool, wrap it with protective tape, and apply protective tape around the related parts, to prevent damage.

Schematic diagrams Connector and Terminal Function Pin Function 1 B-CAN (Low) 2 B-CAN (High) 3 Ground (Assist safety) 4 Assist safety 5 LIN (For IMS) 6 Battery (+) 7 IGN1 8 Driver safety 9 IMS Switch (For IMS) / Mirror Common (For Non IMS) 10 Mirror unfolding motor (Non IMS) 11 Mirror folding motor (Non IMS) 12 Mirror horizontal LH (Non IMS) 13 Mirror vertical LH (Non IMS) 14 Mirror vertical RH (Non IMS) 15 Mirror horizontal RH (Non IMS) 16 Ground Repair procedures Inspection Diagnosis With KDS 1.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Vanity Lamp

Repair procedures Removal When removing with a flat-tip screwdriver or remover, wrap protective tape around the tools to prevent damage to components. 1.

Kia Optima DL3 2019-2026 Service and Repair Manual: Power Mosfet

Description and operation Description It is installed to the DATC and adjusts the fan rpm by precisely controlling the voltage applied to the blower motor. Repair procedures Inspection 1. Turn the ignition switch ON.

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Body Electrical System

- Battery

- Motor Driven Power Steering

- New on site

- Most important about car