Kia Optima DL3: Wiper/Washer / Washer Motor

Repair procedures

| Inspection |

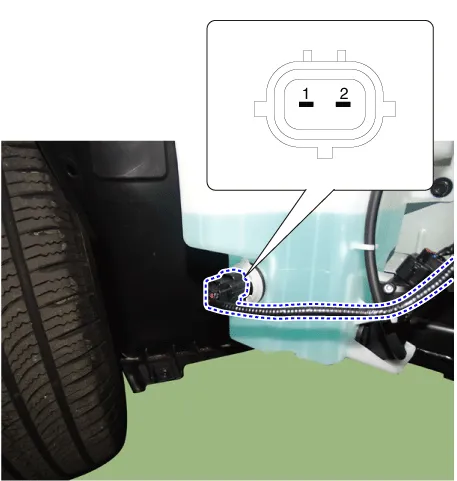

Washer Motor

| 1. |

With the washer motor connected to the reservoir tank, fill the reservoir tank with water.

|

| 2. |

Connect positive (+) battery cables to terminal 2 and negative (-) battery cables to terminal 1 respectively. |

| 3. |

Check that the motor operates normally and the washer motor runs and water sprays from the front nozzles. |

| 4. |

If they are abnormal, replace the washer motor.

|

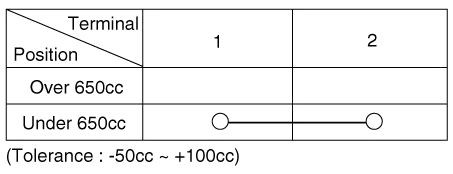

Washer Fluid Level Sensor

| 1. |

Disconnect the negative battery terminal. |

| 2. |

Drain the washer fluid less than 650 cc. |

| 3. |

Check for continuity between the No. 1 and No.2 terminal in each float position. There should be continuity when the float is down. There should be no continuity when the float is up. |

| 4. |

If the continuity is not as specified, replace the washer fluid level switch

|

| Removal |

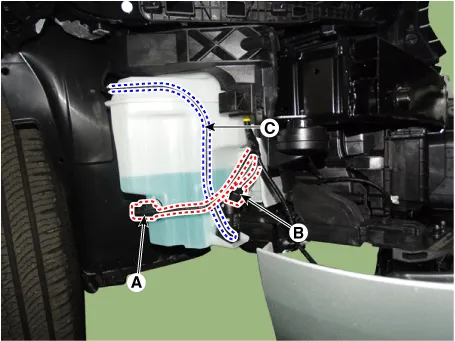

Washer Motor

| 1. |

Disconnect the negative battery terminal. |

| 2. |

Remove the engine room under cover. G 2.0 NU MPI (Refer to Engine Mechanical System - "Engine Room Under Cover") G 2.5 GDI THETA II (Refer to Engine Mechanical System - "Engine Room Under Cover") |

| 3. |

Disconnect the connector (B) and then remove the washer motor (C) after separating the nozzles (A).

|

Washer Fluid Level Sensor

| 1. |

Disconnect the negative battery terminal. |

| 2. |

Remove the engine room under cover. G 2.0 NU MPI (Refer to Engine Mechanical System - "Engine Room Under Cover") G 2.5 GDI THETA II (Refer to Engine Mechanical System - "Engine Room Under Cover") |

| 3. |

Remove the washer fluid level sensor (A) after disconnecting the connector (B).

|

Reservoir

| 1. |

Disconnect the negative battery terminal. |

| 2. |

Remove the engine room under cover. G 2.0 NU MPI (Refer to Engine Mechanical System - "Engine Room Under Cover") G 2.5 GDI THETA II (Refer to Engine Mechanical System - "Engine Room Under Cover") |

| 3. |

Remove the right side front wheel guard. (Refer to Body - "Front Wheel Guard") |

| 4. |

Remove the reservoir.

|

| Installation |

| 1. |

Install in the reverse order of the removal. |

Repair procedures Replacement 1. If wiper switch needs to be replaced, replace the multifunction switch assembly. (Refer to Body Electrical System - "Multifunction Switch")

Schematic diagrams Connector and Terminal Function

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Smart Key System

Specifications Specifications Smart Key Unit Items Specification Rated voltage DC 12 V Operation voltage DC 9 - 16 V Operation temperature -40 to 185°F (-40 to 85°C) RF Receiver Items

Kia Optima DL3 2019-2026 Service and Repair Manual: Evaporator Core

Repair procedures Replacement 1. Disconnect the negative (-) battery terminal. 2. Remove the heater and blower assembly. (Refer to Heater - "Heater Unit") 3. Loosen the mounting screws, lock pin and remove the evaporator core cover (A).

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Floor Console Assembly

- Front Axle Assembly

- Engine Control Module (ECM)

- New on site

- Most important about car