Kia Optima DL3: Driveshaft Assembly / Front Driveshaft

Components and components location

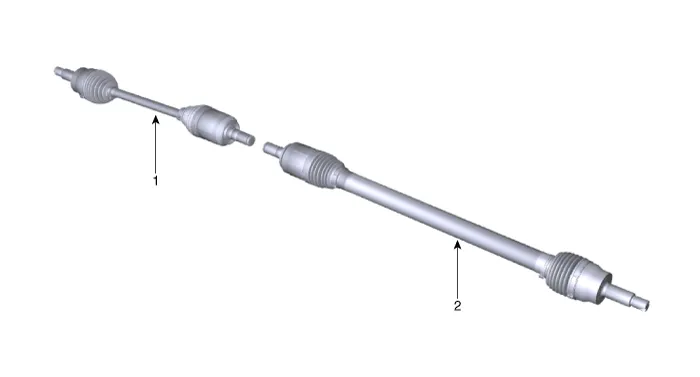

| Components |

| 1. Front driveshaft (LH) |

2. Front driveshaft (RH) |

Repair procedures

| Removal |

| 1. |

Disconnect the (-) battery terminal. |

| 2. |

Remove the front wheel and tire. (Refer to Suspension System - "Wheel") |

| 3. |

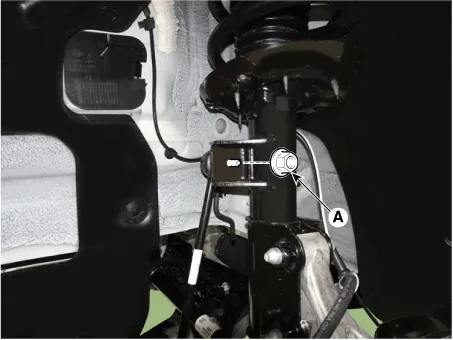

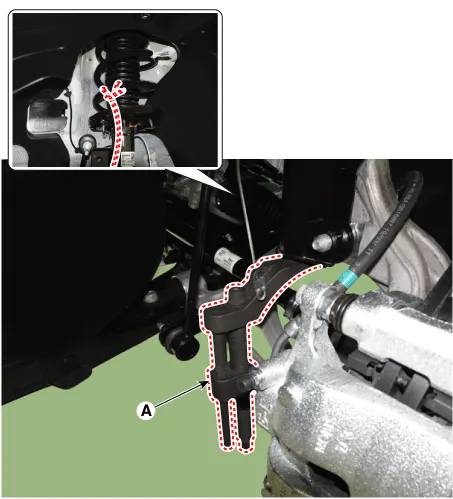

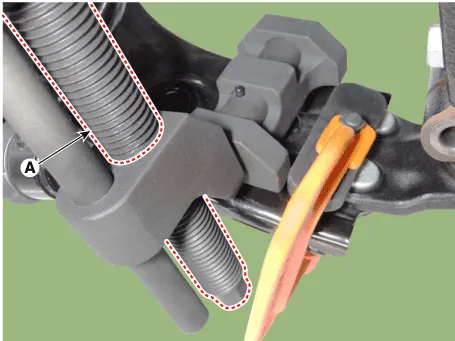

Separate the stabilizer bar link (A) from the strut assembly after loosening the nut.

|

| 4. |

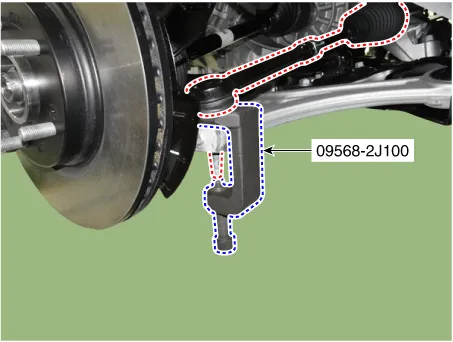

Disconnect the tie rod end ball joint from the knuckle by using the SST (09568-2J100).

|

| 5. |

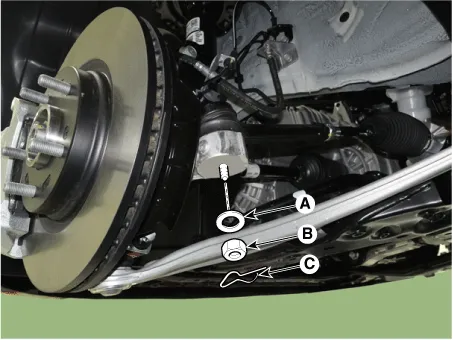

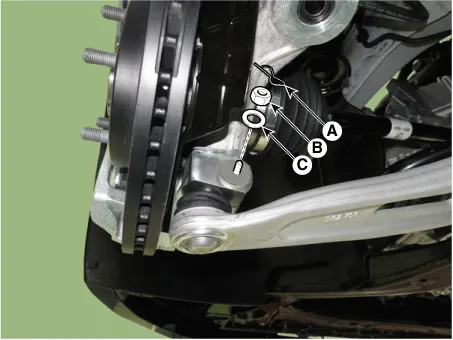

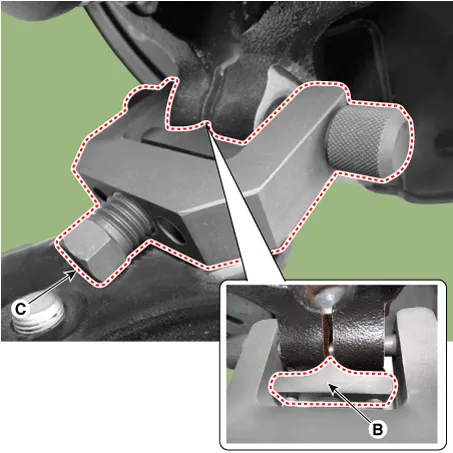

Loosen the lower arm mounting nut (A).

|

| 6. |

Disconnect lower arm ball joint from the knuckle by using the SST (0K545-A9100).

|

| 7. |

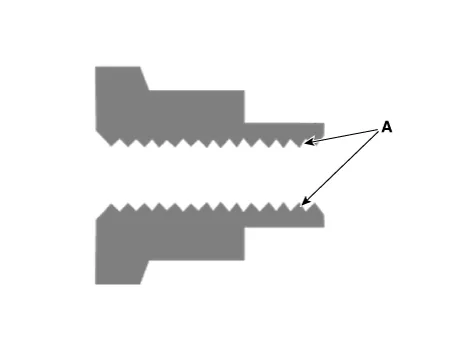

By hammering on a chisel, unlock the driveshaft lock hub nut caulking.

|

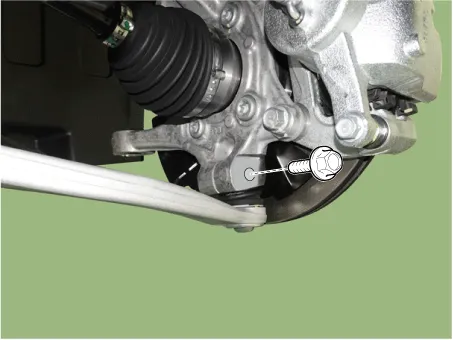

| 8. |

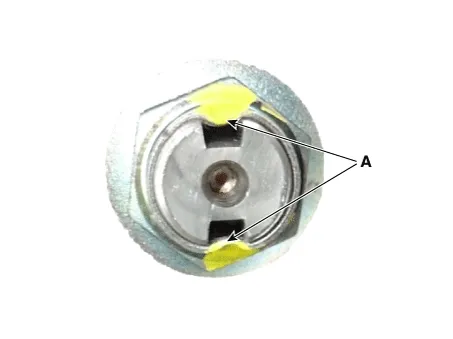

Remove the caulking nut (A) from the front axle.

|

| 9. |

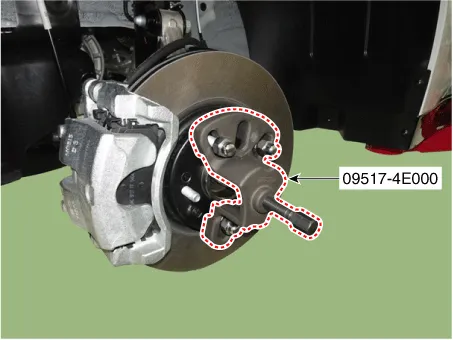

Disconnect the driveshaft from the axle hub by using the SST (09517-4E000).

|

| 10. |

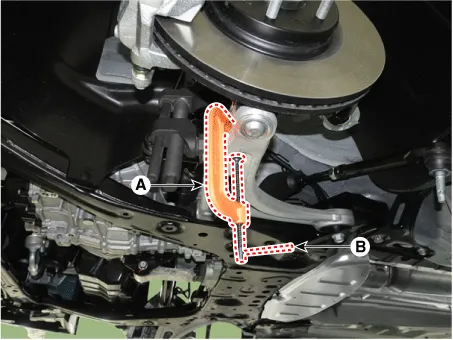

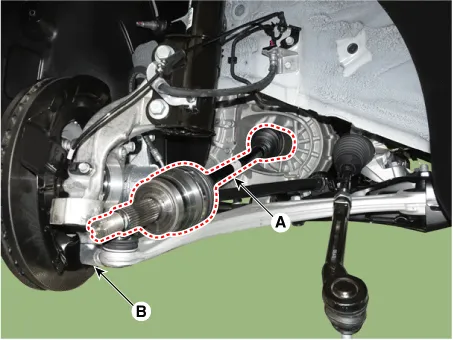

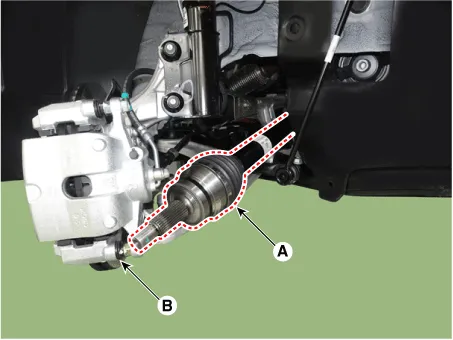

Separate the front driveshaft (A) from the knuckle assembly (B). [LH]

[RH]

|

| 11. |

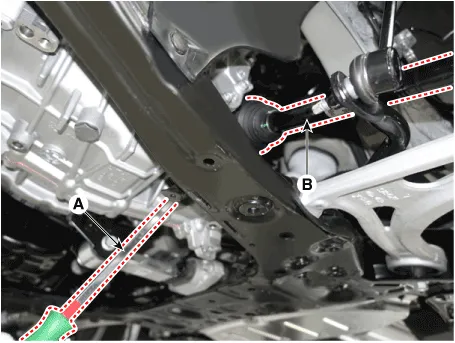

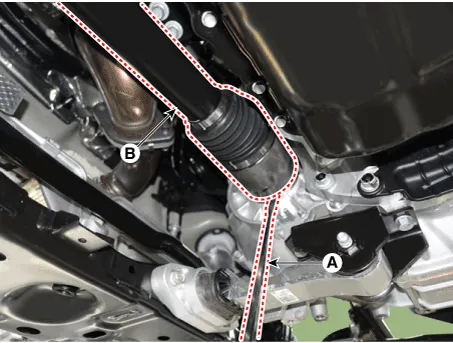

Remove the driveshaft (B) by using the pry bar (A). [LH]

[RH]

|

| Installation |

| 1. |

Install in the reverse order of removal. |

| 2. |

Check the front alignment. (Refer to Suspension System - "Alignment") |

| Inspection |

| 1. |

Check the driveshaft boots for damage and deterioration. |

| 2. |

Check the driveshaft spline for wear or damage. |

| 3. |

Check that there is no water or foreign material in the joint. |

| 4. |

Check the spider assembly for roller rotation, wear or corrosion. |

| 5. |

Check the groove inside the joint case for wear or corrosion. |

| 6. |

Check the dynamic damper for damage or cracks. |

Components and components location Components 1. Wheel side joint assembly 2. Wheel side circlip 3. Wheel side boot band 4.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Mood Lamp Unit

Schematic diagrams Connector and Terminal function Repair procedures Removal When removing with a flat-tip screwdriver or remover, wrap protective tape around the tools to prevent damage to components.

Kia Optima DL3 2019-2026 Service and Repair Manual: Power Window Switch

Schematic diagrams Connector and Terminal Function Power Window Main Switch Pin Function 1 B-CAN (Low) 2 B-CAN (High) 3 Ground (Assist safety) 4 Assist safety 5

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Cooling System

- Rear Bumper Assembly

- Charging System

- New on site

- Most important about car