Kia Optima DL3: Lubrication System / Oil Pressure Switch

Repair procedures

| Removal and Installation |

| 1. |

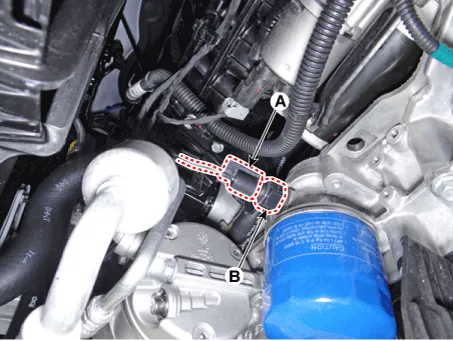

Disconnect the oil pressure switch connector (A) and then remove the oil pressure switch (B).

|

| 2. |

Install in the reverse order of removal.

|

| Inspection |

| 1. |

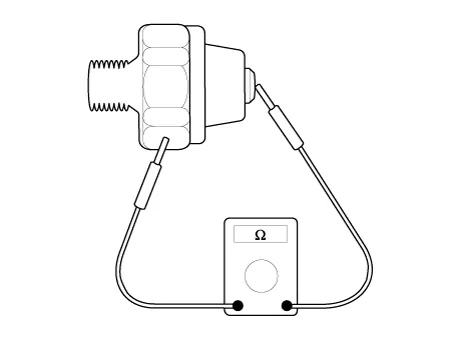

Check the continuity between the terminal and the body with an ohmmeter. If there is no continuity, replace the oil pressure switch.

|

| 2. |

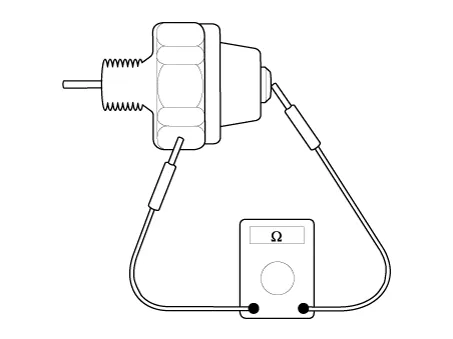

Check the continuity between the terminal and the body when the fine wire is pushed. If there is continuity even when the fine wire is pushed, replace the switch. |

| 3. |

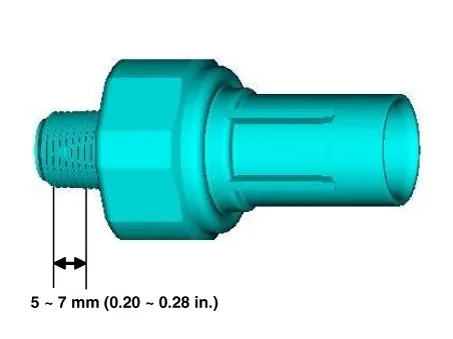

If there is no continuity when a 50 kPa (0.50 kgf/cm², 7.25 psi) is applied through the oil hole, the switch is operating properly. Check for air leakage. If air leaks, the diaphragm is broken. Replace it.

|

Components and components location Components 1. Oil screen gasket 2. Oil screen 3. Oil pan Repair procedures Removal 1.

Repair procedures Removal and Installation 1. Remove the oil level gauge (A). 2. Install in the reverse order of removal.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Power Door Lock Switch

Repair procedures Inspection Power Window Main Switch Diagnosis With KDS 1. In the body electrical system, failure can be quickly diagnosed by using the vehicle diagnostic system (KDS). The diagnostic system (KDS) provides the following information.

Kia Optima DL3 2019-2026 Service and Repair Manual: Power Mosfet

Description and operation Description It is installed to the DATC and adjusts the fan rpm by precisely controlling the voltage applied to the blower motor. Repair procedures Inspection 1. Turn the ignition switch ON.

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Thermostat

- Suspension System

- Engine Electrical System

- New on site

- Most important about car