Kia Optima DL3: Hydraulic System / Underdrive Brake Control Solenoid Valve (UD/B_VFS)

Specifications

| Specification |

|

Item |

Specification |

|

Control type |

N/H (Normal High) |

|

Control pressure (kpa (kgf/cm², psi)) |

0 - 1,569.06 (0 - 16, 0 - 227.57) |

|

Currency (mA) |

0 - 1,100 |

|

Coil resistance(Ω) |

5.3 ± 0.3 |

Description and operation

| Description |

| • |

Underdrive brake control solenoid valve is a Variable Force Solenoid (VFS) type. |

| • |

When TCM supplies variable current to solenoid valve, hydraulic pressure of underdrive brake is controlled by solenoid valve.

|

Underdrive brake control solenoid valve operation table

|

|

UD/B_VFS |

|

N/H |

|

|

N, P |

● |

|

1 |

|

|

2 |

|

|

3 |

|

|

4 |

|

|

5 |

● |

|

6 |

● |

|

R |

● |

● : Connected status

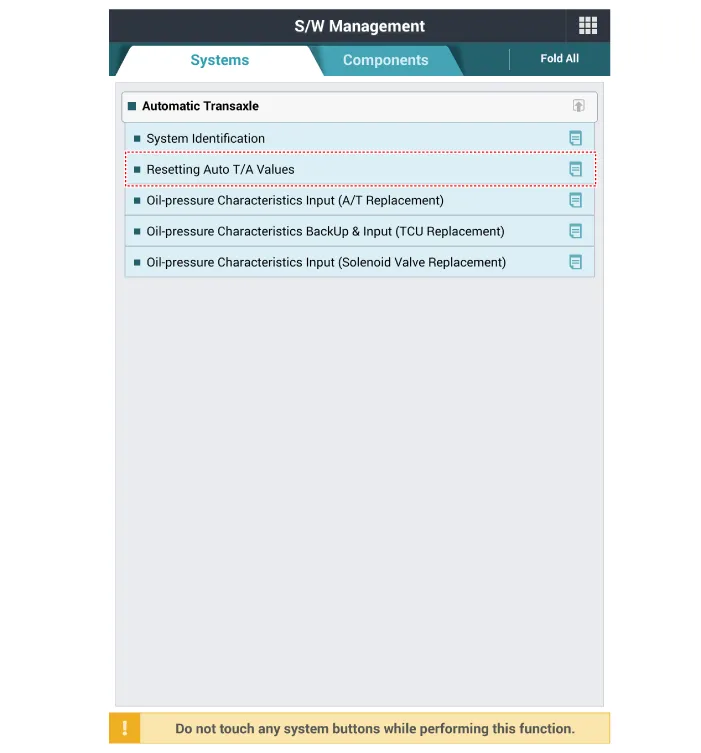

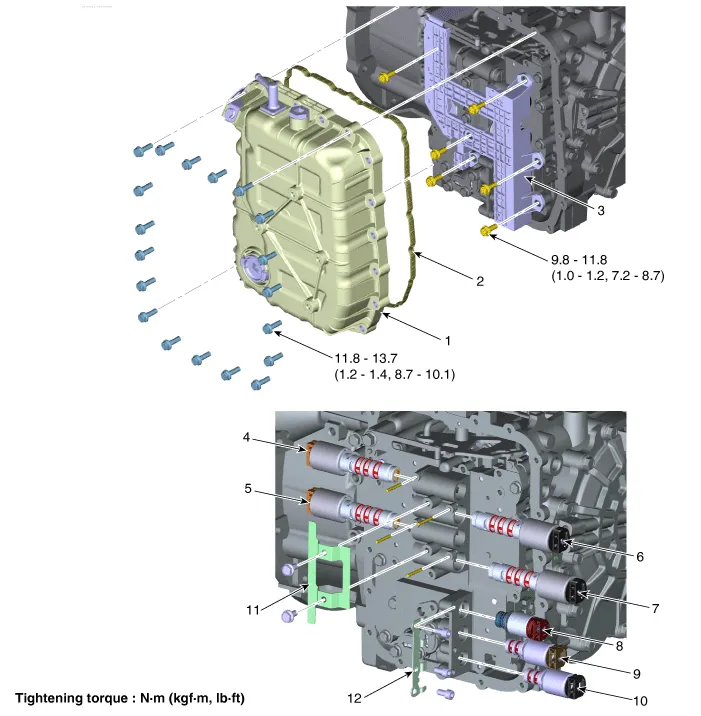

Components and components location

| Component Location |

| 1. Valve Body Cover |

8. SS-A ON/OFF Solenoid Valve

|

| 2. Valve Body Gasket |

9. Torque Converter Control Solenoid

Valve |

| 3. Main Harness |

10. Line Pressure Control Solenoid

Valve |

| 4. 26 Brake Control Solenoid

Valve |

11. Support Bracket |

| 5. 35R Clutch Control Solenoid

Valve |

12. Support Bracket |

| 6. Underdrive Brake Control Solenoid

Valve |

|

| 7. Overdrive Clutch Control Solenoid

Valve |

Repair procedures

| Inspection |

| 1. |

The automatic transaxle system can be more quickly diagnosed for troubles by using the vehicle diagnostic system (KDS). KDS provides the following information.

|

| Component inspection |

| 1. |

Switch "OFF" ignition. |

| 2. |

Remove the air cleaner assembly. (Refer to Engine Mechanical System - "Air cleaner") |

| 3. |

Remove the battery and battery tray. (Refer to Engine Electrical System - "Battery") |

| 4. |

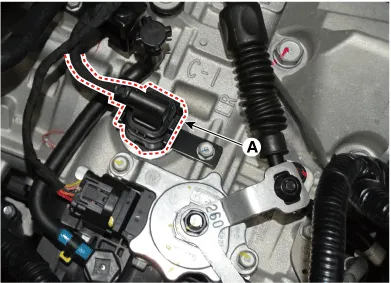

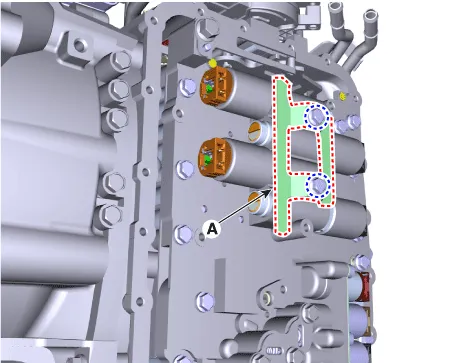

Disconnect the solenoid valve connector (A).

|

| 5. |

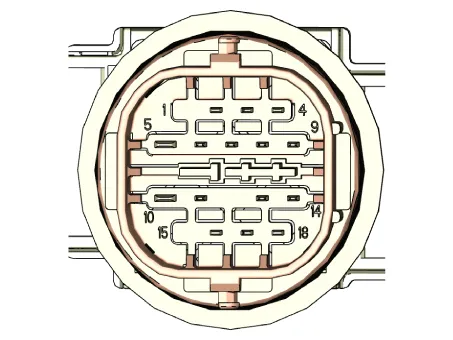

Measure the resistance between power terminal (5) and signal terminal (16).

|

| Removal |

|

| 1. |

Remove the under cover. (Refer to Engine Mechanical System - "Engine Room Under Cover") |

| 2. |

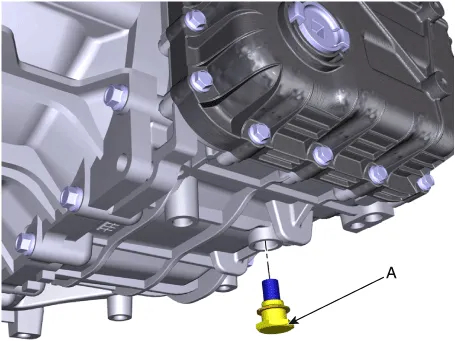

Remove the ATF drain plug (A), allow the fluid to drain out and then reinstall the drain plug.

|

| 3. |

Remove the air duct and air cleaner assembly. (Refer to Engine Mechanical System - "Air cleaner") |

| 4. |

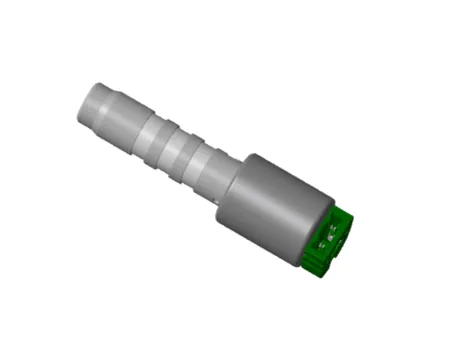

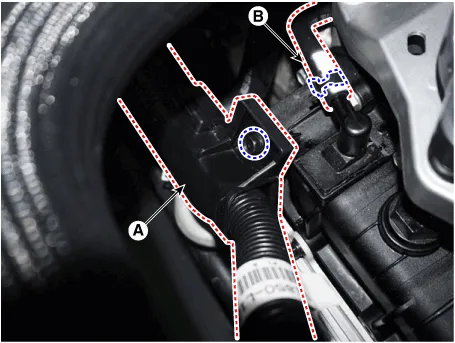

Remove the fixing clip (A) and the air breather hose (B).

|

| 5. |

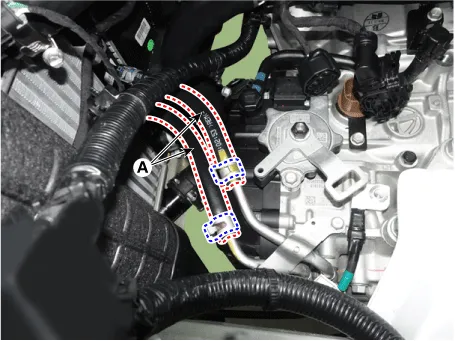

Separate the ATF cooler hose (A).

|

| 6. |

Lift the vehicle after loosening valve body cover upper bolts. |

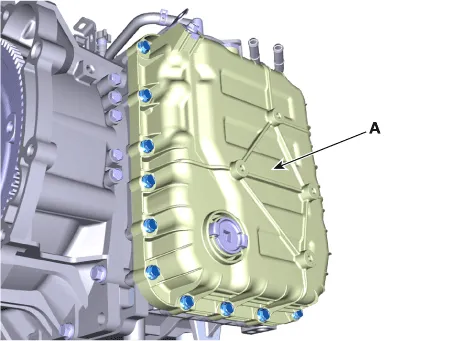

| 7. |

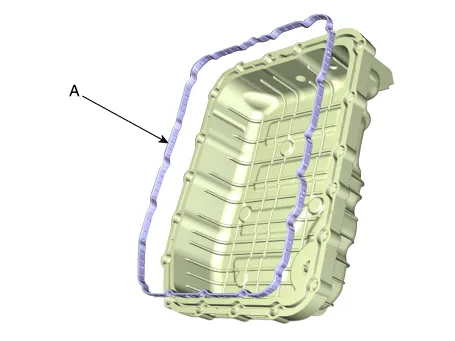

Remove the valve body cover (A) by loosening bolts.

|

| 8. |

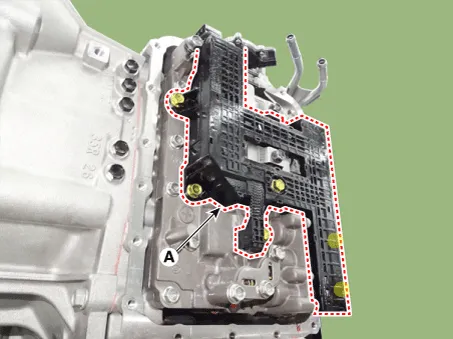

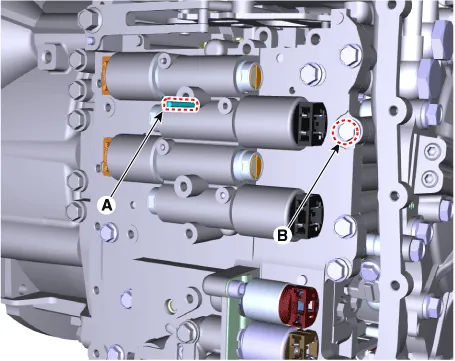

Remove the main harness (A) after removing the bolts.

|

| 9. |

Remove solenoid valve support bracket (A) after loosening the bolts.

|

| 10. |

Remove the solenoid valve fixing pin (A) and loosen the valve body mounting bolt (B).

|

| 11. |

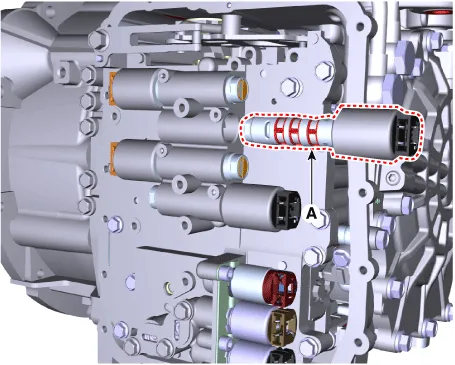

Remove the underdrive brake control solenoid valve (A).

|

| Installation |

| 1. |

Install in the reverse order of removal.

|

| 2. |

Perform the procedures below after installing.

|

Specifications Specification Item Specification Control type N/L (Normal Low) Control pressure (kpa (kgf/cm², psi)) 0 - 1,569.

Specifications Specification Item Specification Control type N/H (Normal High) Control pressure (kpa (kgf/cm², psi)) 0 - 1,569.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Power Door Lock Switch

Repair procedures Inspection Power Window Main Switch Diagnosis With KDS 1. In the body electrical system, failure can be quickly diagnosed by using the vehicle diagnostic system (KDS). The diagnostic system (KDS) provides the following information.

Kia Optima DL3 2019-2026 Service and Repair Manual: Power Door Lock Module

Repair procedures Inspection When prying with a flat-tip screwdriver or use a prying trim tool, wrap it with protective tape, and apply protective tape around the related parts, to prevent damage.

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Charging System

- Front Axle Assembly

- Lift And Support Points

- New on site

- Most important about car