Kia Optima DL3: Emission Control System

Service data

| Specifications |

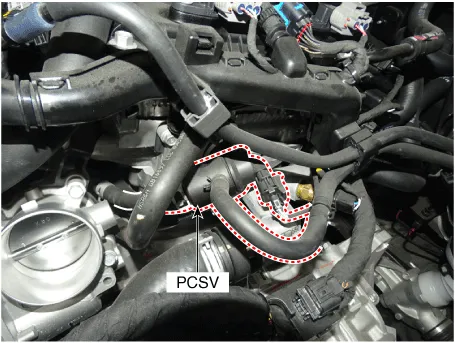

Purge Control Solenoid Valve (PCSV)

▷ Specification

|

Item |

Specification |

|

Coil Resistance (Ω) |

22.0 - 26.0 [20°C (68°F)] |

Tightening torque

| Tightening Torques |

|

Item |

kgf.m |

N.m |

lb-ft |

|

Positive Crankcase Ventilation (PCV) Valve |

0.2 - 0.3 |

1.96 - 2.94 |

1.45 - 2.17 |

Description and operation

| Description |

Emissions Control System consists of three major systems.

| • |

Crankcase Emission Control System prevents blow-by gas from releasing into the atmosphere. This system recycles gas back into the intake manifold (Closed Crankcase Ventilation Type). |

| • |

Evaporative Emission Control System prevents evaporative gas from releasing into the atmosphere. This system burns gas at appropriate engine operating condition after gathering it in the canister. |

| • |

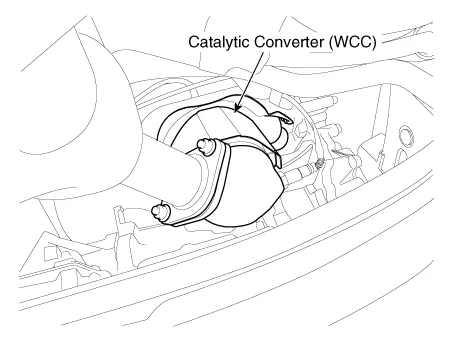

Exhaust Emission Control System converts the three pollutants [hydrocarbons (HC), carbon monoxide (CO), and oxides of nitrogen (NOx)] into harmless substances by using the 3-way catalytic converter. |

Troubleshooting

| Troubleshooting |

|

Symptom |

Suspect Area |

|

Engine will not start or stuggle to start |

Vapor hose damaged or disconnected |

|

Engine stuggle to start |

Malfunction of the Purge Control Solenoid Valve |

|

Rough idle or engine stalls |

Vapor hose damaged or disconnected |

|

Malfunction of the PCV valve |

|

|

Rough idle |

Malfunction of the Evaporative Emission Control System |

|

Excessive oil consumption |

Positive crankcase ventilation line clogged |

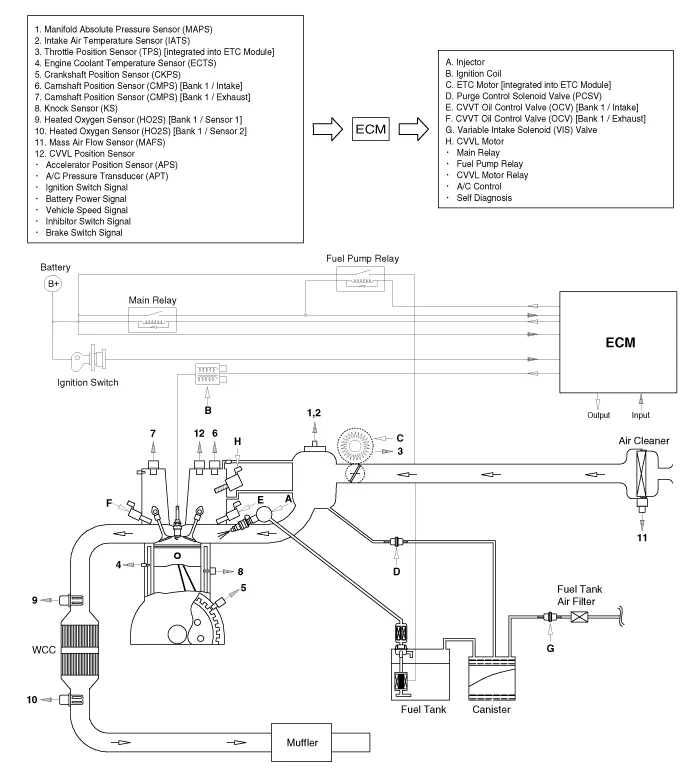

Schematic diagrams

| Schematic Diagram |

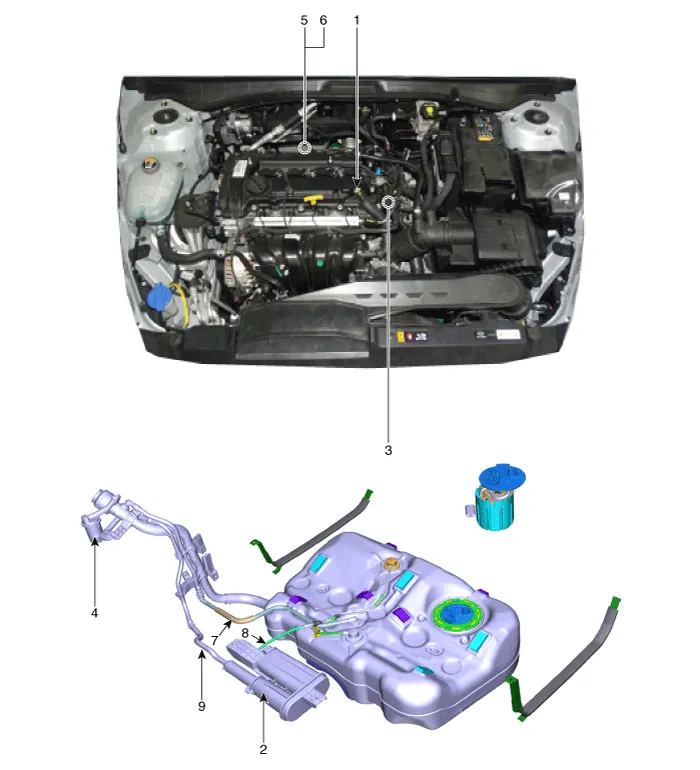

Components and components location

| Components Location |

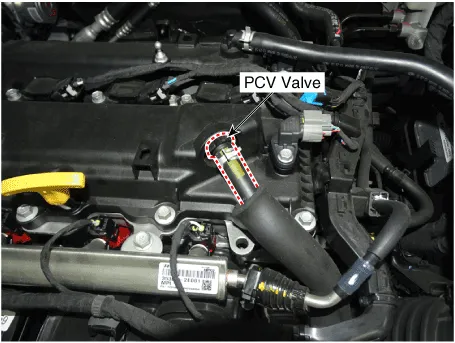

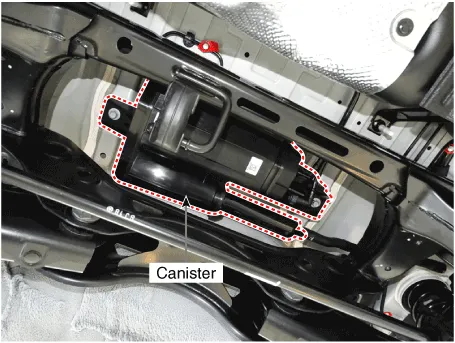

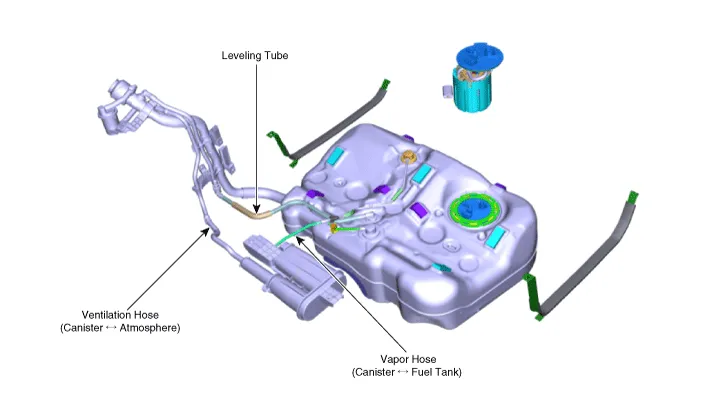

| 1. PCV valve 2. Canister 3. Purge control solenoid valve (PCSV) 4. Fuel Tank Air Filter 5. Catalytic converter (WCC) |

6. Catalytic converter (UCC)

7. Leveling Tube 8. Vapor Hose (Canister ↔ Fuel Tank) 9. Ventilation Hose (Canister ↔ Atmosphere) |

|

1. PCV valve |

2. Canister |

|

|

|

|

3. Purge control solenoid valve (PCSV) |

4. Fuel Tank Air Filter |

|

|

|

|

5. Catalytic converter (WCC) |

6. Catalytic converter (UCC) |

|

|

|

|

7. Leveling Tube 8. Vapor Hose (Canister ↔ Fuel Tank) 9. Ventilation Hose (Canister ↔ Atmosphere) |

|

|

|

|

Repair procedures Inspection 1. Disconnect the negative battery (-) terminal. 2. Remove the fuse box cover.

Schematic diagrams Schematic Diagram Repair procedures Inspection 1. After disconnecting the vapor hose from the PCV valve, remove the PCV valve.

Other information:

Kia Optima DL3 2019-2025 Service and Repair Manual: Heated Seats Only

Components and components location Components Front Seat Heater 1. Front seat back heater 2. Front seat cushion heater 3. Front seat heater unit / ventilation unit Rear Seat Heater 1.

Kia Optima DL3 2019-2025 Service and Repair Manual: Smart Key Unit

Schematic diagrams Connector and Terminal Function Pin Function Connector A Connector B Connector C Connector D 1 - Front washer switch (Output) - Driver outside handle switch (Input)

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Lift And Support Points

- Front Axle Assembly

- Body (Interior and Exterior)

- New on site

- Most important about car