Kia Optima DL3: Engine Control System / ETC (Electronic Throttle Control) System

Specifications

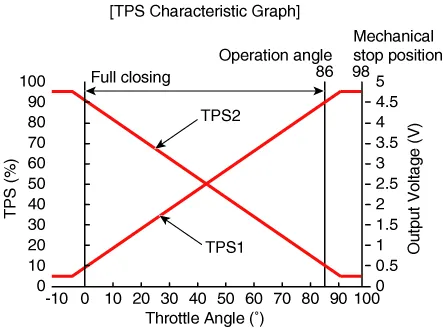

| Specification |

|

Throttle angle (°) |

Output voltage (V) [Vref = 5.0V] |

|

|

TPS1 |

TPS2 |

|

|

0 |

0.5 |

4.5 |

|

10 |

0.96 |

4.05 |

|

20 |

1.41 |

3.59 |

|

30 |

1.87 |

3.14 |

|

40 |

2.32 |

2.68 |

|

50 |

2.78 |

2.23 |

|

60 |

3.23 |

1.77 |

|

70 |

3.69 |

1.32 |

|

80 |

4.14 |

0.86 |

|

90 |

4.6 |

0.41 |

|

98 |

4.65 |

0.35 |

|

C.T (0) |

0.5 |

4.5 |

|

W.O.T (86) |

4.41 |

0.59 |

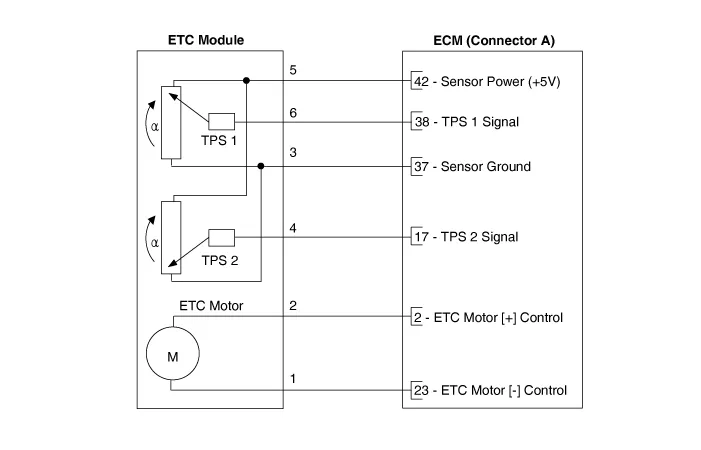

[ETC Motor]

|

Item |

Specification |

|

Coil Resistance (Ω) |

0.3 - 100 [20°C(68°F)] |

Description and operation

| Description |

| • |

The Electronic Throttle Control (ETC) System consists of a throttle body with an integrated control motor and Throttle Position Sensor (TPS). |

| • |

Instead of the traditional throttle cable, an Accelerator Position Sensor (APS) is used to receive driver input. |

| • |

The ECM uses the APS signal to calculate the target throttle angle; the position of the throttle is then adjusted via ECM control of the ETC motor. |

| • |

The TPS signal is used to provide feedback regarding throttle position to the ECM. |

| • |

Using ETC, precise control over throttle position is possible; the need for external cruise control modules/cables is eliminated. |

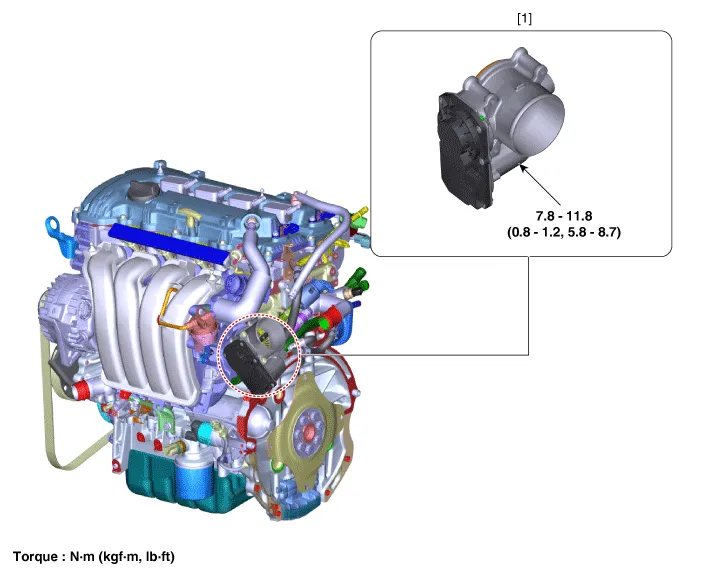

Components and components location

| Components Location |

| 1. ETC (Electronic Throttle Control)

|

Schematic diagrams

| Circuit Diagram |

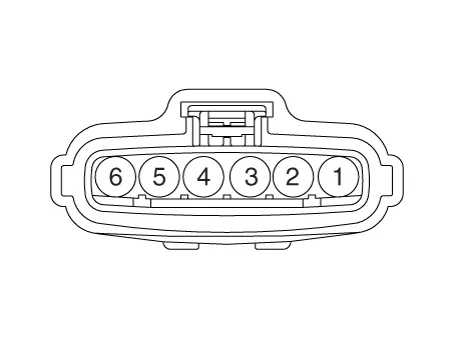

Harness Connector

Repair procedures

| Inspection |

| 1. |

The engine control system can be more quickly diagnosed for troubles by using the vehicle diagnostic system (KDS). (Refer to "DTC guide") KDS provides the following information.

|

Throttle Position Sensor (TPS)

| 1. |

Connect the KDS on the Data Link Connector (DLC). |

| 2. |

Start the engine and measure the output voltage of TPS 1 and 2 at C.T. and W.O.T.

|

||||||||||||||||||||||||||||||||||||||||||||

ETC Motor

| 1. |

Disconnect the ETC module connector. |

| 2. |

Measure resistance between the ETC module terminals 1 and 2.

|

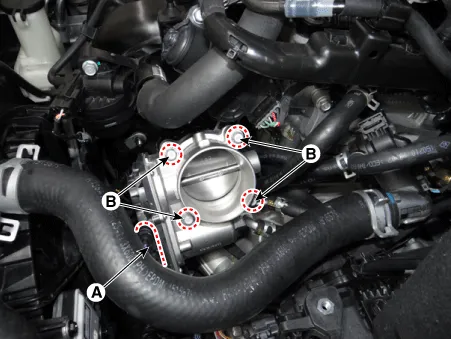

| Removal |

| 1. |

Disconnect the negative battery terminal. |

| 2. |

Remove the air cleaner. (Refer to Engine Mechanical System - "Air Cleaner") |

| 3. |

After disconnecting the connector (A), remove the ETC module by loosening the bolts (B).

|

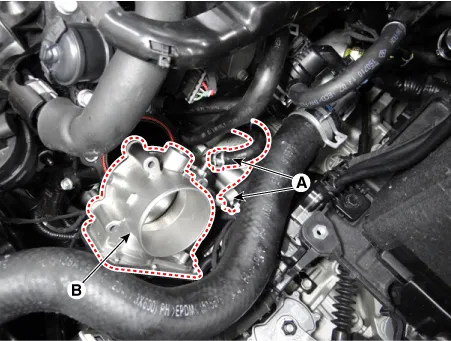

| 4. |

Separate the coolant hoses (A) from the ETC module (B).

|

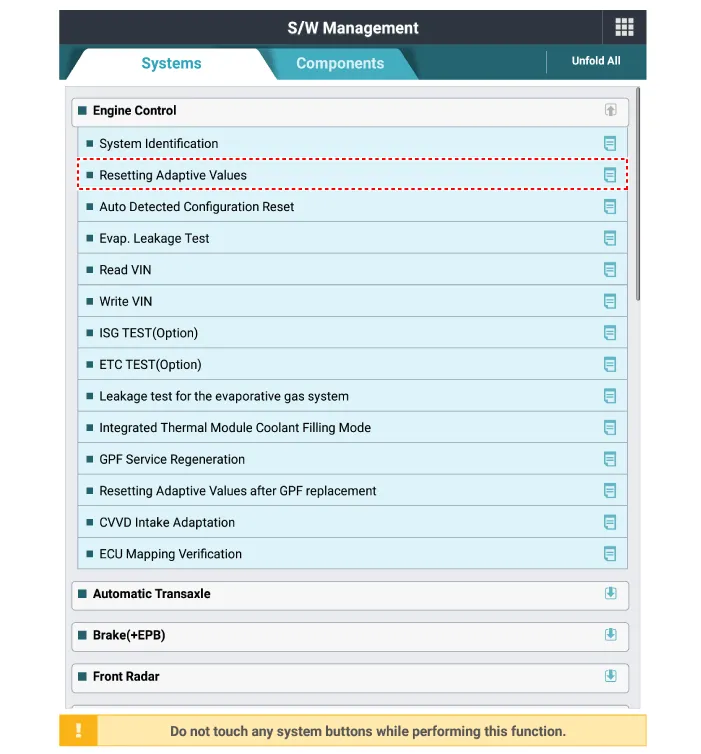

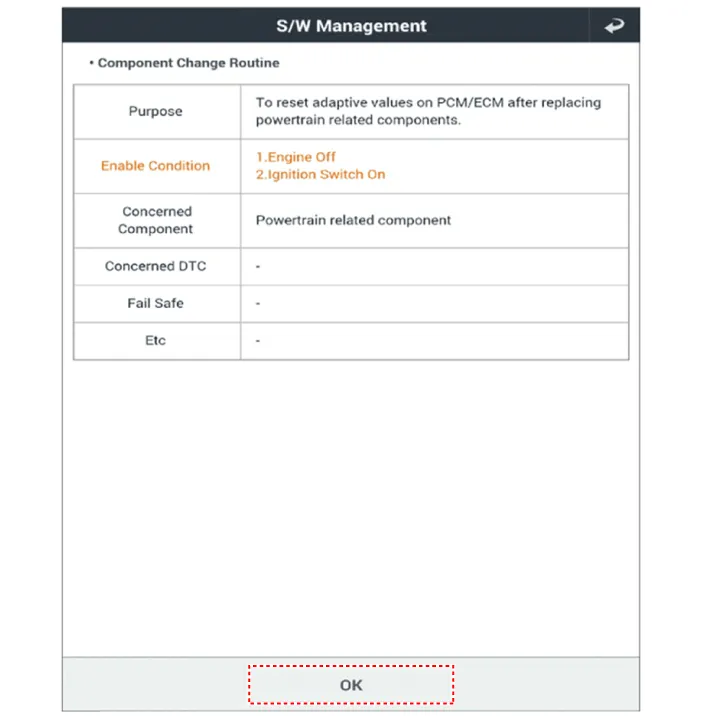

| Installation |

|

| 1. |

Install in the reverse order of removal. |

| 2. |

Supplement the engine coolant. (Refer to Engine Mechanical System - "Coolant") |

| 3. |

Reset the ECM adaptive values after replacing the ETC.

|

| 4. |

Perform the ETC learning procedure. (Refer to ETC (Electronic Throttle Control) System - "Adjustment") |

| Adjustment |

|

| 1. |

Wait for 1 minute with the ignition switch ON. |

| 2. |

Start the engine and hold the idle status for 15 minutes. |

| 3. |

Waif for 1 minute with the ignition switch OFF. |

| 4. |

Restart the engine, check that the idle speed is stable. |

| Cleaning |

| 1. |

Remove the ETC. (Refer to ETC - "Removal")

|

| 2. |

Clean the pollutant in the throttle body using a soft cloth moistened with cleaning fluid.

|

| 3. |

Install the ETC. (Refer to ETC - "Installation") |

| 4. |

Reset the ETC adaptive value.

|

| 5. |

Perform the ETC learning procedure. (Refer to ETC - "Adjustment") |

Troubleshooting

| Fail-Safe Mode |

|

Item |

Fail-Safe |

|

|

ETC Motor |

Throttle valve stuck at 7° |

|

|

TPS |

TPS 1 fault |

Replace it with TPS 2 |

|

TPS 2 fault |

Replace it with TPS 1 |

|

|

TPS 1,2 fault |

Throttle valve stuck at 7° |

|

|

APS |

APS 1 fault |

Replace it with APS 2 |

|

APS 2 fault |

Replace it with APS 1 |

|

|

APS 1,2 fault |

Engine idle state |

|

When throttle value is stuck at 7°, engine speed is limited at below 1,500rpm and vehicle speed at maximum 40 - 50 km/h (25 - 31 mph) |

Components and components location Component Location 1. Engine Control Module (ECM) Schematic diagrams Connector and Terminal function ECM Terminal Function [Connector A] Pin Function Connected to 1 - 2 ETC Motor [+] control output ETC Motor 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 Sensor ground Engine Coolant Temperature Sensor (ECTS) 16 Engine Coolant Temperature Sensor (ECTS) signal input Engine Coolant Temperature Sensor (ECTS) 17 Throttle Position Sensor (TPS) 2 signal input Throttle Position Sensor (TPS) 2 [ETC Module] 18 - 19 - 20 - 21 Sensor power (+5V) Manifold Absolute Pressure Sensor (MAPS) Camshaft Position Sensor (CMPS) [Bank 1 / Intake] 22 - 23 ETC Motor [-] control output ETC Motor [ETC Module] 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 Electrical load signal input (FR) Alternator 32 - 33 - 34 - 35 - 36 - 37 Sensor ground Throttle Position Sensor (TPS) 1, 2 [ETC Module] 38 Throttle Position Sensor (TPS) 1 signal input Throttle Position Sensor (TPS) 1 [ETC Module] 39 - 40 Alternator PWM control output Alternator 41 - 42 Sensor power (+5V) Throttle Position Sensor (TPS) 1, 2 [ETC Module] 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 Sensor ground Camshaft Position Sensor (CMPS) [Bank 1/Exhaust] 57 - 58 - 59 - 60 - 61 Sensor ground Manifold Absolute Pressure Sensor (MAPS) 62 Manifold Absolute Pressure Sensor (MAPS) signal input Manifold Absolute Pressure Sensor (MAPS) 63 Sensor power (+5V) Camshaft Position Sensor (CMPS) [Bank 1 / Exhaust] 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74 Sensor ground Crankshaft Position Sensor (CKPS) 75 - 76 - 77 Camshaft Position Sensor (CMPS) [Bank 1 / Exhaust] signal input Camshaft Position Sensor (CMPS) [Bank 1 / Exhaust] 78 Sensor ground Camshaft Position Sensor (CMPS) [Bank 1 / Intake] 79 - 80 - 81 - 82 - 83 VG (Virtual Ground) Heated Oxygen Sensor [Bank 1 / Sensor 1] 84 VRC (Current Adjust) Heated Oxygen Sensor [Bank 1 / Sensor 1] 85 - 86 - 87 - 88 - 89 - 90 - 91 - 92 - 93 - 94 - 95 Crankshaft Position Sensor (CKPS) signal input Crankshaft Position Sensor (CKPS) 96 - 97 - 98 Camshaft Position Sensor (CMPS) [Bank 1 / Intake] signal input Camshaft Position Sensor (CMPS) [Bank 1 / Intake] 99 Sensor ground Knock Sensor (KS) 100 Knock Sensor (KS) signal input Knock Sensor (KS) 101 Intake Air Temperature Sensor (IATS) signal input Intake Air Temperature Sensor (IATS) 102 - 103 - 104 VN (NERNST Cell Voltage) Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 1] 105 VIP (Current Pump) Heated Oxygen Sensor [Bank 1 / Sensor 1] [Connector B] Pin Function Connected to 1 Power ground Chassis Ground 2 Power ground Chassis Ground 3 Battery power (B+) Main Relay 4 Power ground Chassis Ground 5 Battery power (B+) Main Relay 6 Battery power (B+) Main Relay 7 - 8 - 9 - 10 Accelerator Position Sensor (APS) 2 signal input Accelerator Position Sensor (APS) 2 11 A/C Pressure Transducer (APT) signal input A/C Pressure Transducer (APT) 12 - 13 - 14 Sensor power (+5V) A/C Pressure Transducer (APT) 15 - 16 Sensor power (+5V) Accelerator Position Sensor (APS) 2 17 Sensor power (+5V) Accelerator Position Sensor (APS) 1 18 Main Relay control output Main Relay 19 Fuel Pump Relay control output Fuel Pump Relay 20 - 21 - 22 Injector (Cylinder #2) control output Injector (Cylinder #3) 23 Injector (Cylinder #3) control output Injector (Cylinder #3) 24 - 25 - 26 - 27 Accelerator Position Sensor (APS) 1 signal input Accelerator Position Sensor (APS) 1 28 Sensor ground Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 2] 29 Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 2] signal input Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 2] 30 - 31 - 32 - 33 - 34 Start Motor relay control output Start Motor relay 35 CVVT Oil Control (OCV) Valve [Bank 1 / Exhaust] control output CVVT Oil Control Valve (OCV) [Bank 1 / Exhaust] 36 CVVT Oil Control (OCV) Valve [Bank 1 / Intake] control output CVVT Oil Control Valve (OCV) [Bank 1 / Intake] 37 - 38 A/C Relay control output A/C Relay 39 Injector (Cylinder #4) control output Injector (Cylinder #3) 40 Ignition Coil (Cylinder #2) control output Ignition Coil (Cylinder #2) 41 Battery power (B+) Ignition Switch 42 - 43 - 44 - 45 Sensor ground Accelerator Position Sensor (APS) 1 46 Sensor ground Accelerator Position Sensor (APS) 2 47 - 48 - 49 - 50 Sensor ground A/C Pressure Transducer (APT) 51 - 52 - 53 - 54 - 55 - 56 Injector (Cylinder #1) control output Injector (Cylinder #1) 57 Ignition Coil (Cylinder #4) control output Ignition Coil (Cylinder #4) 58 - 59 LOCAL-CAN [Low] Other control module, Data Link Connector (DLC) 60 P-CAN [Low] Other control module, Data Link Connector (DLC) 61 Fuel Tank Level Sensor signal input Fuel Tank Level Sensor (FLS) 62 - 63 - 64 - 65 Brake Light Switch signal input Brake Switch 66 Start signal input Ignition Switch 67 Engine speed signal output Power Distribution Module (PDM) 68 Immobilizer communication line Immobilizer control module 69 - 70 - 71 Purge Control Solenoid Valve (PCSV) control output Purge Control Solenoid Valve (PCSV) 72 - 73 Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 1] Heater control output Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 1] 74 Ignition Coil (Cylinder #3) control output Ignition Coil (Cylinder #3) 75 Memory power (B+) Engine Room Fuse & Relay Box (EMS ECU) 76 LOCAL-CAN [High] Other control module, Data Link Connector (DLC) 77 C-CAN [High] Other control module, Data Link Connector (DLC) 78 - 79 Vehicle speed signal input ABS/ESC Control Unit 80 - 81 Wiper Switch Input Signal Integrated Body Control Unit (IBU) 82 - 83 Brake Test Switch signal input Brake Switch 84 - 85 - 86 Cooling Fan Relay control output Cooling Fan Relay 87 - 88 Variable Intake Solenoid (VIS) Valve control output Variable Intake Solenoid (VIS) Valve 89 - 90 Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 2] Heater control output Heated Oxygen Sensor (HO2S) [Bank 1 / Sensor 2] 91 Ignition Coil (Cylinder #1) control output Ignition Coil (Cylinder #1) [NON-Immobilizer type] Repair procedures Inspection 1.

Specifications Specification Manifold Absolute Pressure Sensor (MAPS) Pressure Output Voltage (V) kPa kgf/cm² psi 20 0.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Condenser

Components and components location Components Location 1. Condenser Repair procedures Inspection 1. Check the condenser fins for clogging and damage. If clogged, clean them with water, and blow them with compressed air.

Kia Optima DL3 2019-2026 Service and Repair Manual: Photo Sensor

Description and operation Description The photo sensor is located at the center of the defrost nozzles. The photo sensor contains a photovoltaic (sensitive to sunlight) diode. The solar radiation received by its light receiving portion, generates an electromotive force in proportion to the amount of radiation received which is

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Battery

- Charging System

- Headlamps

- New on site

- Most important about car