Kia Optima DL3: Hydraulic System / Fluid

Repair procedures

| Inspection |

Automatic Transaxle Fluid (ATF) Level Check

When checking the ATF level, be careful not to allow foreign substance (like dust) to enter through the filler hole. |

| 1. |

Remove the inhibitor switch. (Refer to Automatic Transaxle Control System - "Inhibitor Switch") |

| 2. |

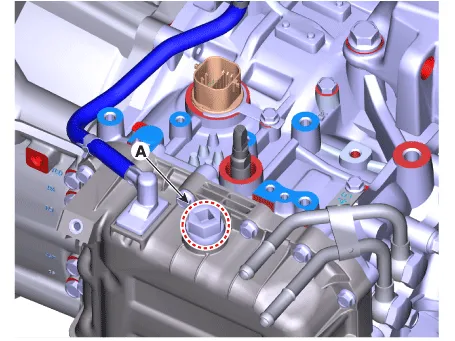

Add 0.7 liters of ATF SP-IV through the ATF filler hole after removing the eyebolt (A).

|

| 3. |

Start the engine to warm up the ATF.

|

| 4. |

Check by using KDS that the temperature of the ATF is between 50°C and 60°C (122 - 140°F). |

| 5. |

Move the shift lever slowly from "P" to "D", then back to "P". Repeat this sequence two times and then move the shift lever to "P" range.

|

| 6. |

Remove the under cover. (Refer to Engine Mechanical System - "Engine Room Under Cover") |

| 7. |

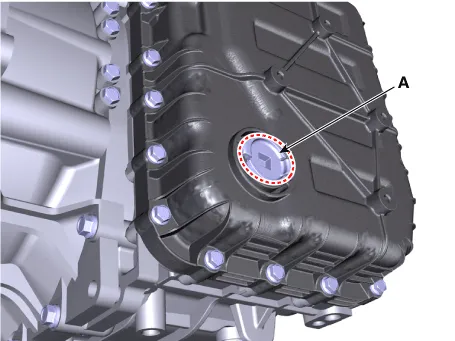

Lift the vehicle and remove the ATF level plug (A) from the valve body cover.

|

| 8. |

Check the ATF level.

|

| 9. |

Install the ATF level plug (A).

|

| 10. |

Lower the vehicle and install the eyebolt (A).

|

| 11. |

Install the inhibitor switch. (Refer to Automatic Transaxle Control System - "Inhibitor Switch") |

| Replacement |

| 1. |

Remove the under cover. (Refer to Engine Mechanical System - "Engine Room Under Cover") |

| 2. |

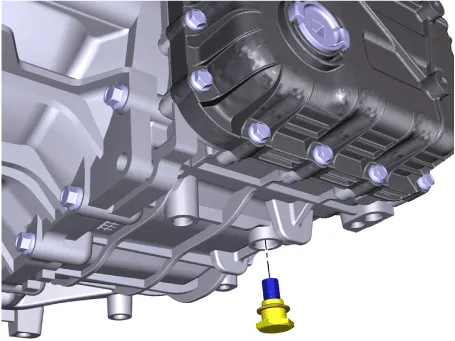

Remove the ATF drain plug (A), allow the fluid to drain out and then reinstall the drain plug.

|

| 3. |

Remove the inhibitor switch. (Refer to Automatic Transaxle Control System - "Inhibitor Switch") |

| 4. |

Remove the eyebolt (A).

|

| 5. |

Fill the automatic transaxle with about 5.0 liters of ATF SP-IV through the ATF filler hole. |

| 6. |

Perform the ATF level check procedure. (Refer to Fluid - "Inspection") |

Components and components location Components Location 1. Automatic transaxle 2. Oil filter 3. Mechanical oil pump 4.

Repair procedures Replacement It is not recommended to replace the valve body .

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Auto Defogging Sensor

Description and operation Description The auto defogging sensor is installed on the front window glass. The sensor judges and sends signal if moisture occurs to blow out wind for defogging. The air conditioner control module receives signal from the sensor and restrains moisture and eliminate defog by controlling the intake actu

Kia Optima DL3 2019-2026 Service and Repair Manual: Intake Actuator

Components and components location Components Location 1. Intake actuator Description and operation Description The intake actuator is located at the blower unit. It regulates the intake door by a signal from the control unit.

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Cooling System

- Timing Chain

- Suspension System

- New on site

- Most important about car