Kia Optima DL3: Automatic Transaxle Control System / Shift Lever

Components and components location

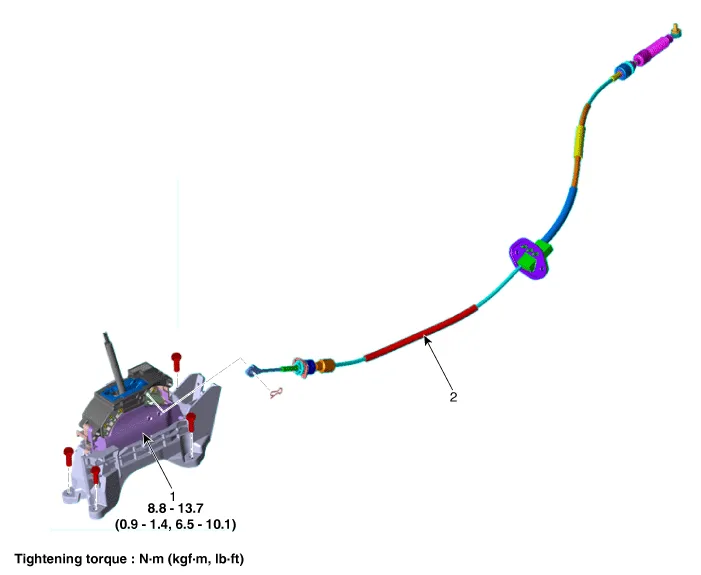

| Component |

| 1. Shift Lever Assembly |

2. Shift Cable Assembly |

Repair procedures

| Removal |

| 1. |

Shift the gear to "N". |

| 2. |

Remove the floor console assembly. (Refer to Body - "Floor Console Assembly") |

| 3. |

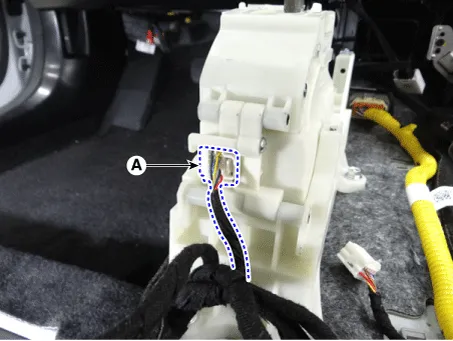

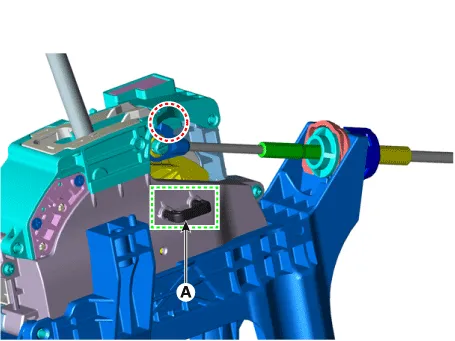

Disconnect the main connector (A).

|

| 4. |

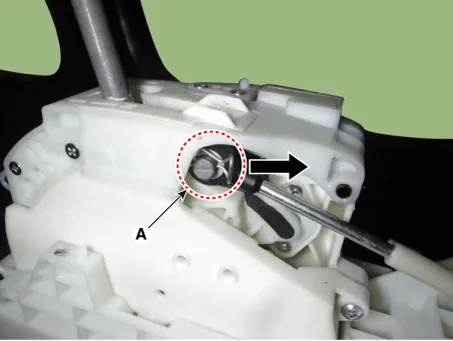

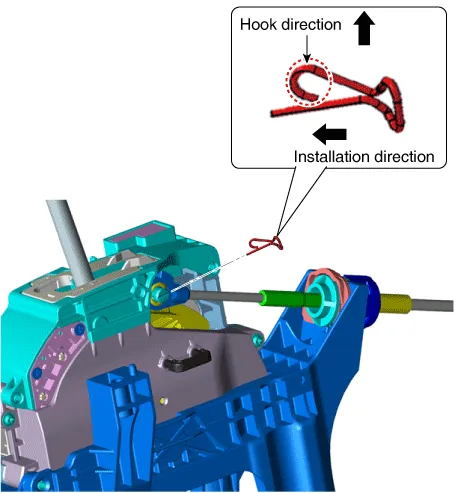

Remove the snap pin (A).

|

| 5. |

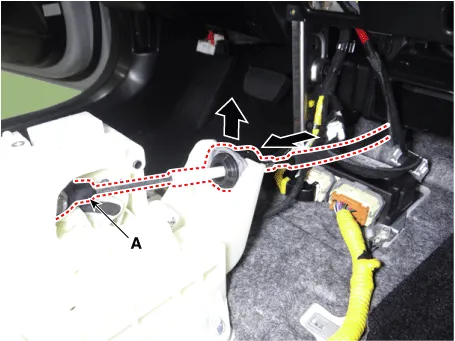

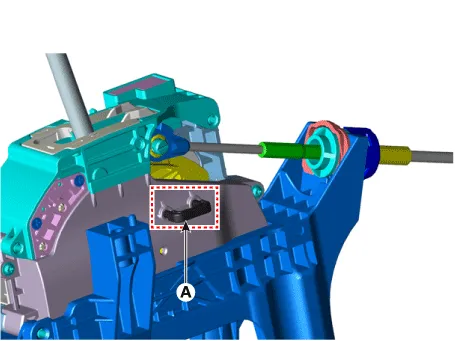

Remove the shift cable (A) from the shift lever.

|

| 6. |

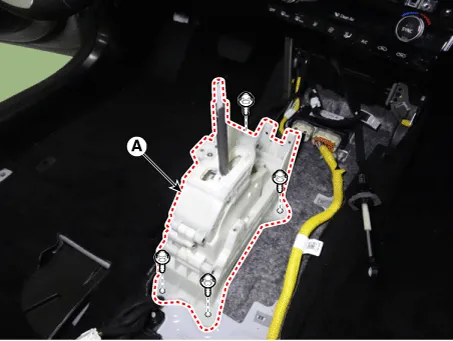

Remove the shift lever assembly (A).

|

| Installation |

| 1. |

Install in the reverse order of removal.

|

Specifications Specification Item Specification Power supply (V) 4.5 - 5.5 V Output type Shifting range (P/R/N/D) Non-contact(2 channel PWM signal) Start, Back-up lamp Contact Description and operation Description • The inhibitor switch mounted on the upper of transaxle and connected with shifter lever.

Components and components location Component 1. Shift Lever Assembly 2. Shift Cable Assembly Repair procedures Removal 1.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Washer Switch

R

Kia Optima DL3 2019-2026 Service and Repair Manual: Heating, Ventilation and Air Conditioning

Service data Service Data Air Conditioner ltem Specification Compressor Type 6SAS14 Oil type & Capacity ND-OIL 12 80 ± 10 cc (2.82 ± 0.

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Engine Control Module (ECM)

- Front Axle Assembly

- Engine Control / Fuel System

- New on site

- Most important about car