Kia Optima DL3: Power Train / Vapor Hose and Fuel Filler Cap

Repair procedures

| Inspection |

Vapor hose

| 1. |

Check all the clamps for tightness and the connections for leakage. |

| 2. |

Visually check the vapor lines and hoses for cracks, leaks, loose connections, or deformation. |

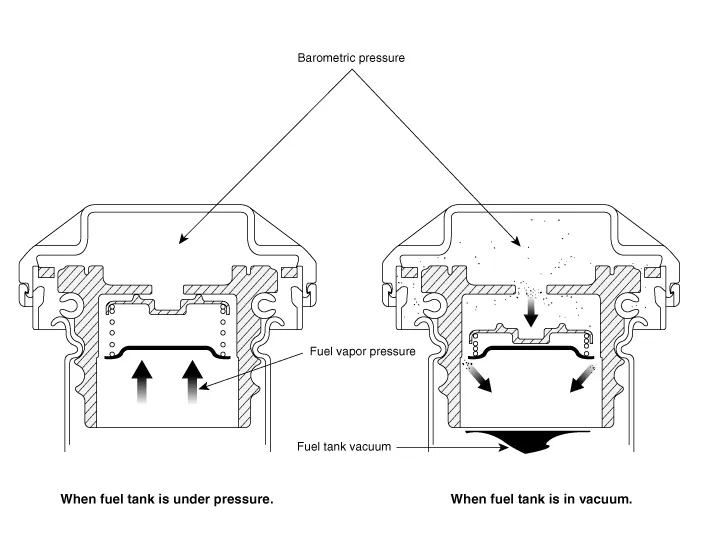

Fuel filler cap

| 1. |

Visually check that the fuel tank cap assembly and gasket (A) are not deformed or damaged.

|

Repair procedures Inspection Automatic Transaxle Fluid (ATF) Level Check When checking the ATF level, be careful not to allow foreign substance (like dust) to enter through the filler hole.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Power Door Mirrors

C

Kia Optima DL3 2019-2026 Service and Repair Manual: Auto Defogging Sensor

Description and operation Description The auto defogging sensor is installed on the front window glass. The sensor judges and sends signal if moisture occurs to blow out wind for defogging. The air conditioner control module receives signal from the sensor and restrains moisture and eliminate defog by controlling the intake actu

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Charging System

- Timing Chain

- Piston and Connecting Rod

- New on site

- Most important about car