Kia Optima DL3: Engine Control System / CVVT Oil Control Valve (OCV)

Specifications

| Specification |

|

Item |

Specification |

|

Coil Resistance (Ω) |

9.4 - 10.4 [20°C(68°F)] |

Description and operation

| Description |

| • |

Continuous Variable Valve Timing (CVVT) system advances or retards the valve timing of the intake and exhaust valve in accordance with the ECM control signal which is calculated by the engine speed and load. |

| • |

By controlling CVVT, the valve over-lap or under-lap occurs, which makes better fuel economy and reduces exhaust gases (NOx, HC) and improves engine performance through reduction of pumping loss, internal EGR effect, improvement of combustion stability, improvement of volumetric efficiency, and increase of expansion work. |

| • |

This system consists of |

| – |

the CVVT Oil Control Valve (OCV) which supplies the engine oil to the cam phaser or cuts the engine oil from the cam phaser in accordance with the PWM (Pulse With Modulation) control signal of ECM. |

| – |

the CVVT Oil Temperature Sensor (OTS) which measures the engine oil temperature, |

| – |

the Cam Phaser which varies the cam phase by using the hydraulic force of the engine oil. |

| • |

The engine oil transferred from the CVVT oil control valve changes the cam phase in the direction of the engine rotation (Intake Advance / Exhaust Retard) or the opposite (Intake Retard / Exhaust Advance) by rotating the rotor connected to the camshaft inside the cam phaser. |

[Intake]

[Exhaust]

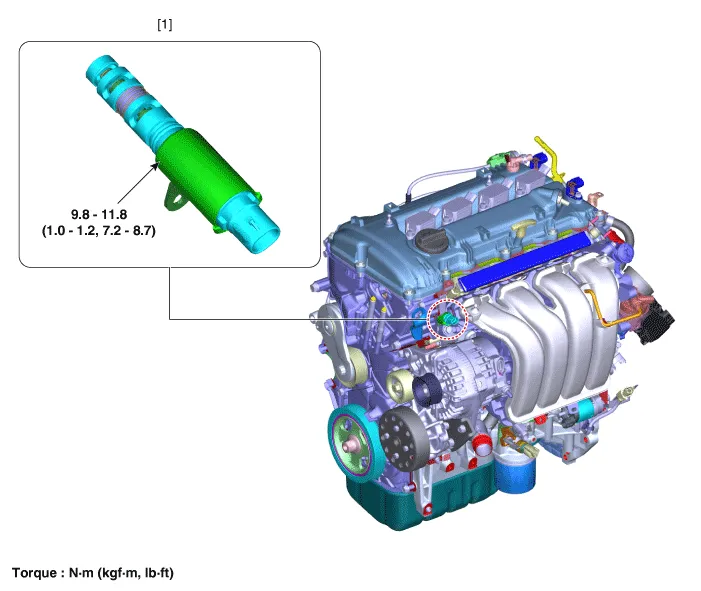

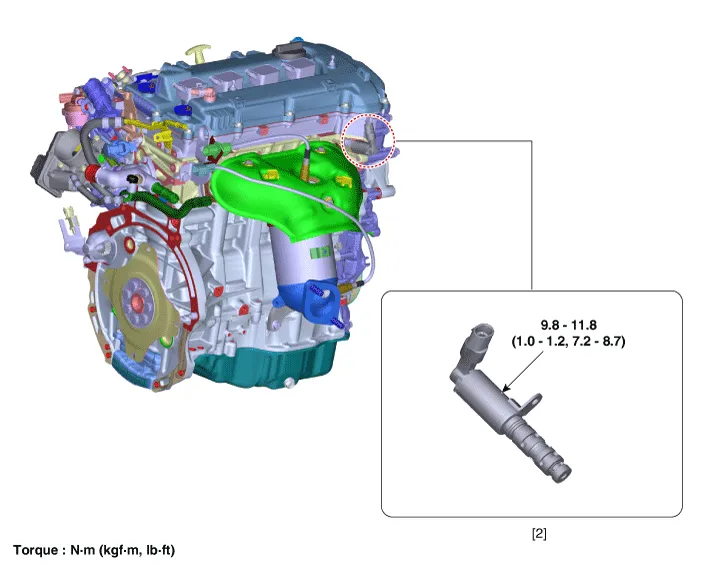

Components and components location

| Components Location |

| 1. Oil Control Valve (OCV) -

Intake |

2. Oil Control Valve (OCV) -

Exhaust |

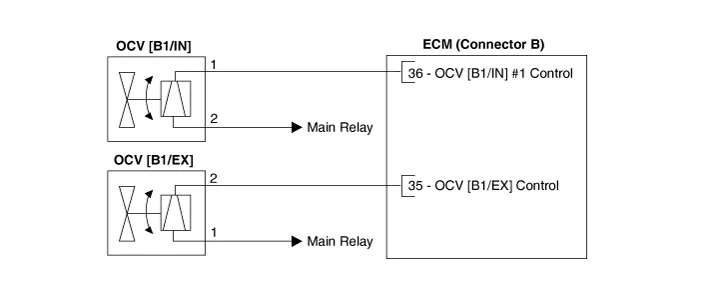

Schematic diagrams

| Circuit Diagram |

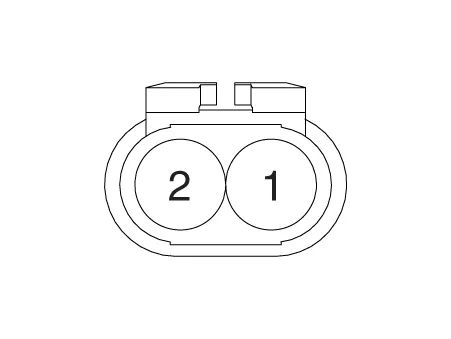

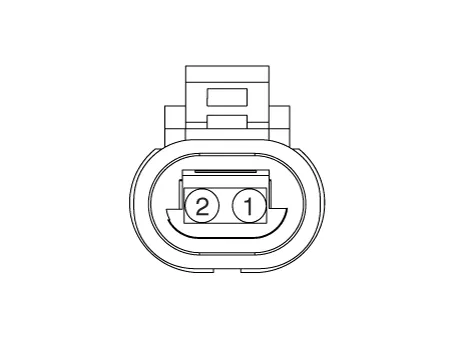

Harness Connector

[Intake]

[Exhaust]

Repair procedures

| Inspection |

| 1. |

The engine control system can be more quickly diagnosed for troubles by using the vehicle diagnostic system (KDS). (Refer to "DTC guide") KDS provides the following information.

|

| Component Inspection |

| 1. |

Turn the ignition switch OFF. |

| 2. |

Disconnect the OCV connector. |

| 3. |

Measure resistance between the OCV terminals 1 and 2. |

| 4. |

Check that the resistance is within the specification.

|

| Removal |

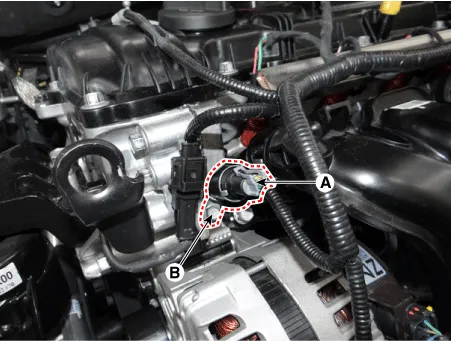

| [Intake] |

| 1. |

Disconnect the negative battery terminal. |

| 2. |

Disconnect the CVVT oil control valve connector (A). |

| 3. |

Remove the CVVT oil control valve after loosening the mounting bolt (B).

|

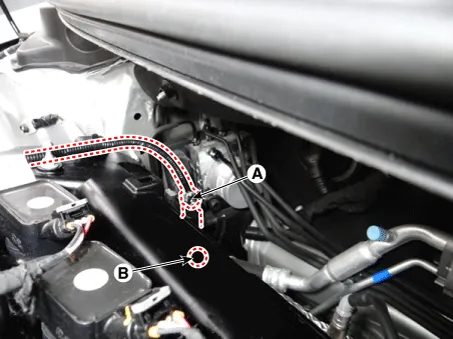

| [Exhaust] |

| 1. |

Disconnect the negative battery terminal. |

| 2. |

Disconnect the CVVT oil control valve connector (A). |

| 3. |

Remove the CVVT oil control valve after loosening the mounting bolt (B).

|

| Installation |

|

| 1. |

Install in the reverse order of removal. |

Specifications Specification Accelerator Output Voltage (V) [Vref = 5.0V] Position APS1 APS2 C.

Specifications Specification Item Specification Coil resistance (Ω) 30.0 - 35.0 [22°C (71.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: License Lamps

Repair procedures Removal 1. Disconnect the negative battery terminal. 2. Remove the lcense lamp (A) by pressing the hook. 3. Disconnect the lcense lamp connector (A).

Kia Optima DL3 2019-2026 Service and Repair Manual: In-car Sensor

Description and operation Description The In-car air temperature sensor is built in the heater & A/C control unit. The sensor contains a thermistor which measures the temperature of the inside. The signal decided by the resistance value which changes in accordance with perceived inside temperature, is delivered to heater co

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Timing Chain

- Engine Control / Fuel System

- Engine Control Module (ECM)

- New on site

- Most important about car