Kia Optima DL3: Driveshaft and axle / Front Axle Assembly

Components and components location

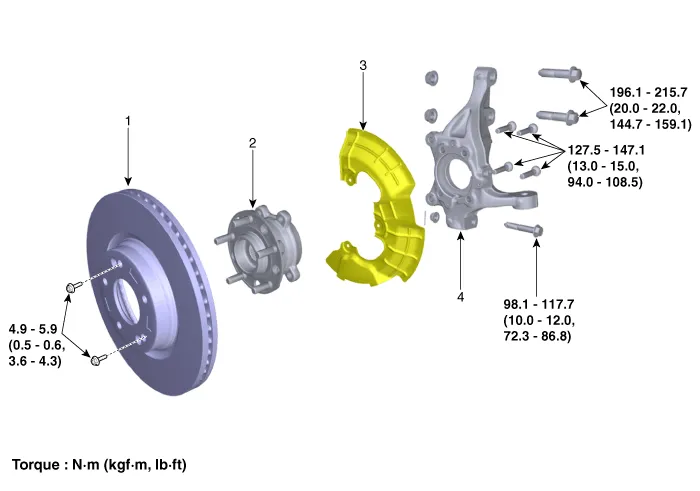

| Components |

| 1. Front brake disc 2. Front hub assembly |

3. Dust cover 4. Front knuckle |

Repair procedures

| Removal |

| 1. |

Disconnect the (-) battery terminal. |

| 2. |

Remove the front wheel and tire. (Refer to Suspension System - "Wheel") |

| 3. |

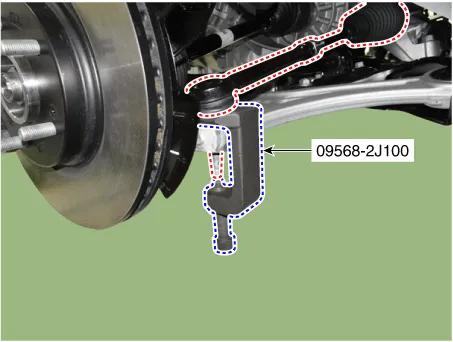

Disconnect the tie rod end ball joint from the knuckle by using the SST (09568-2J100).

|

| 4. |

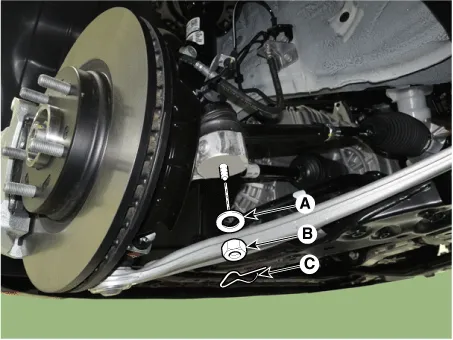

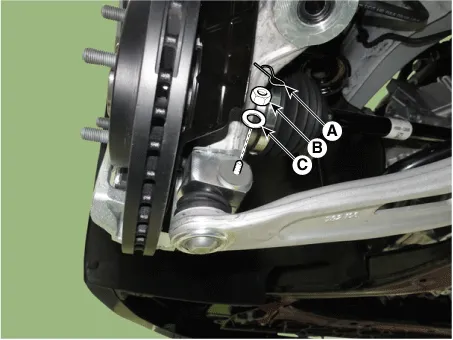

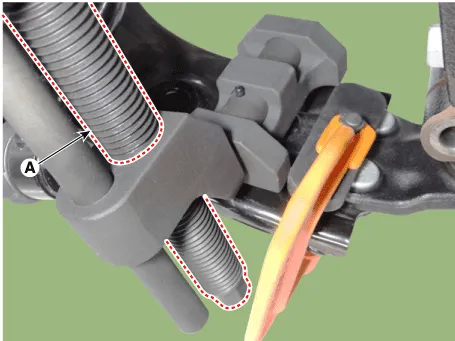

Loosen the lower arm mounting nut (A).

|

| 5. |

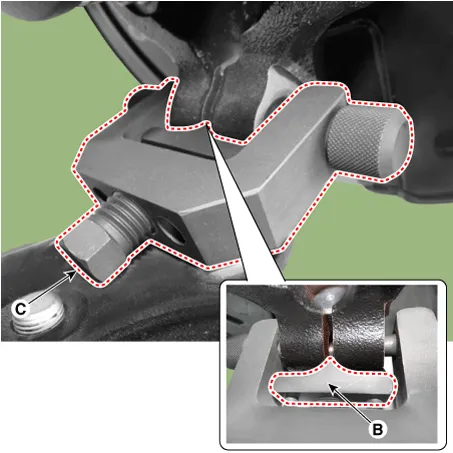

Disconnect lower arm ball joint from the knuckle by using the SST (0K545-A9100).

|

| 6. |

By hammering on a chisel, unlock the driveshaft lock hub nut caulking.

|

| 7. |

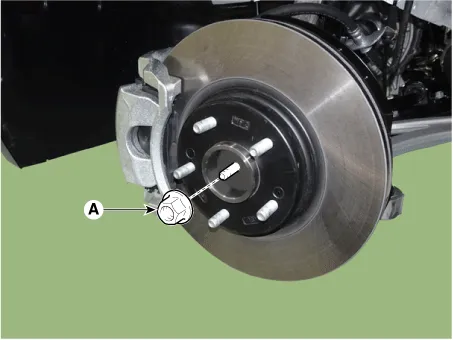

Remove the caulking nut (A) from the front axle.

|

| 8. |

Disconnect the driveshaft from the axle hub by using the SST (09517-4E000).

|

| 9. |

Remove the front brake caliper assembly. (Refer to Brake System - "Front Brake Caliper") |

| 10. |

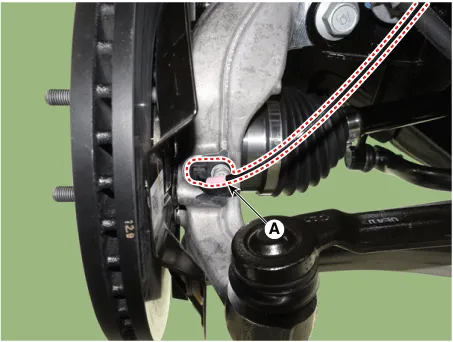

Separate the front wheel speed sensor (A) after loosening the bolt.

|

| 11. |

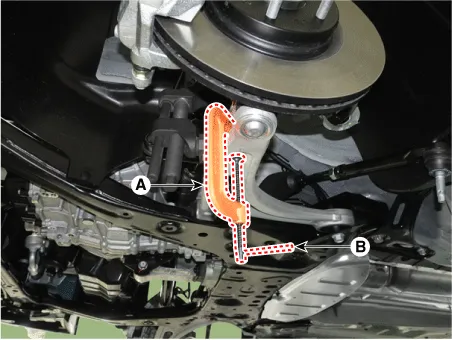

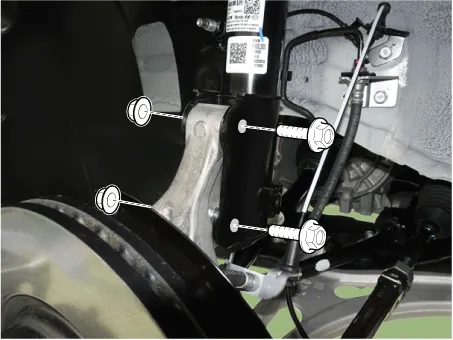

Remove the front axle (A) after loosening the front strut bolts and nuts.

|

| Installation |

| 1. |

Install in the reverse order of removal. |

| 2. |

Check the front alignment. (Refer to Suspension System - "Alignment") |

| Disassembly |

| 1. |

Remove the front brake disc (A) after loosening the screws.

|

| 2. |

Loosen the hub bearing mounting bolts.

|

| 3. |

Remove the dust cover (A) from the knuckle.

|

| Reassembly |

| 1. |

Assemble in the reverse order of disassembly. |

| Inspection |

| 1. |

Check the hub for cracks and the splines for wear. |

| 2. |

Check the brake disc for scoring and damage. |

| 3. |

Check the knuckle for cracks. |

| 4. |

Check the bearing for cracks or damage. |

Tightening torque Tightening Torque Item N·m kgf·m lb·ft Front Tire wheel hub nut 107.

Components and components location Components 1. Rear brake disc 2. Hub bearing assembly 3. Dust cover 4. Rear carrier Repair procedures Removal 1.

Other information:

Kia Optima DL3 2019-2025 Service and Repair Manual: Room Lamp

Repair procedures Removal When removing with a flat-tip screwdriver or remover, wrap protective tape around the tools to prevent damage to components. 1.

Kia Optima DL3 2019-2025 Service and Repair Manual: Walk-in Switch

Components and components location Component Location 1. Walk-in switch Repair procedures Removal When prying with a flat-tip screwdriver or use a prying trim tool, wrap it with protective tape, and apply prote

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Engine Mechanical System

- Engine Control / Fuel System

- Headlamps

- New on site

- Most important about car