Kia Optima DL3: Automatic Transaxle Control System / Transaxle Oil Temperature Sensor (Main Harness)

Specifications

Item

|

Specification

|

Type

|

*NTC thermistor

|

Temp.[(°C)°F] / Resistance (kΩ)

|

(-40)-40 / 48.1

|

(-20)-4.0 / 15.6

|

(0)32.0 / 5.88

|

(20)68.0 / 2.51

|

(40)104.0 / 1.19

|

(60)140.0 / 0.61

|

(80)176.0 / 0.32

|

(100)212.0 / 0.18

|

(120)248.0 / 0.10

|

(140)284.0 / 0.06

|

(150)302.0 / 0.05

|

*NTC : Negative Temperature Coefficient

Description and operation

| • |

The sensor used is a thermistor (NTC) in which resistance changes with

temperature variation.

|

| • |

When the TCM supplies about 5 V of power to sensor, the sensor output

value changes depending on ATF temperature.

|

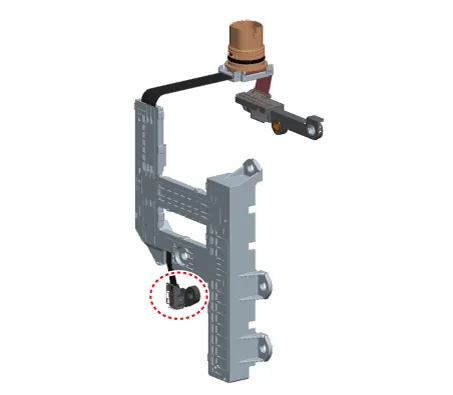

| • |

Oil temperature sensor is installed on the valve body integrated with

a main harness module.

|

Functions

| • |

Transaxle oil temperature sensor monitors the temperature of ATF and

conveys the readings to TCM.

|

| • |

Data produced by this sensor is used to identify torque converter clutch

activation and deactivation zones within the low temperature and high temperature

range and to compensate hydraulic pressure levels during gear changes.

|

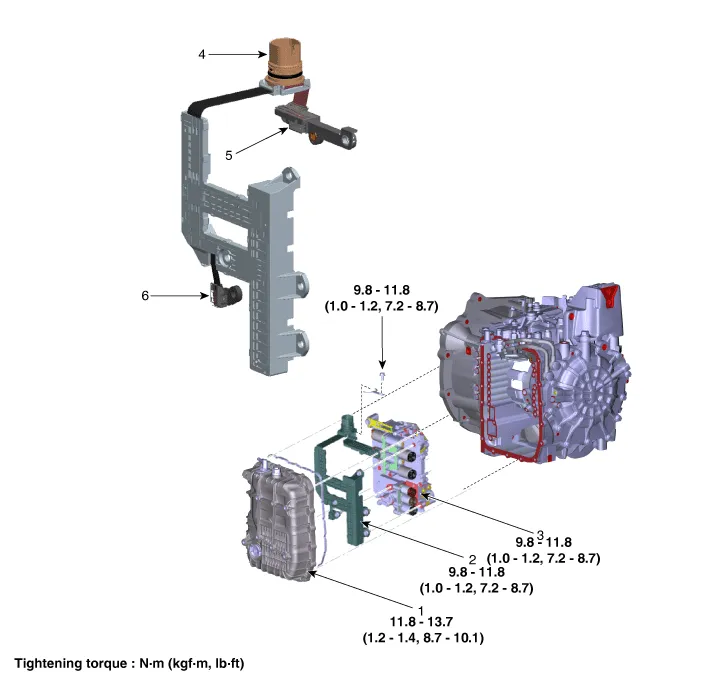

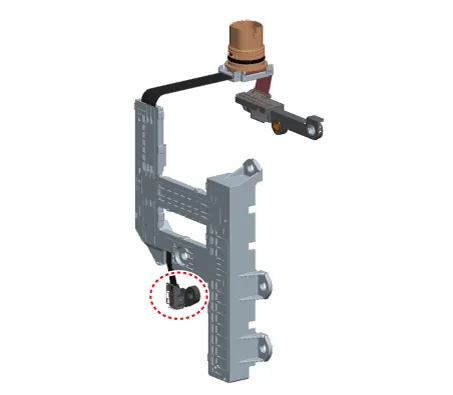

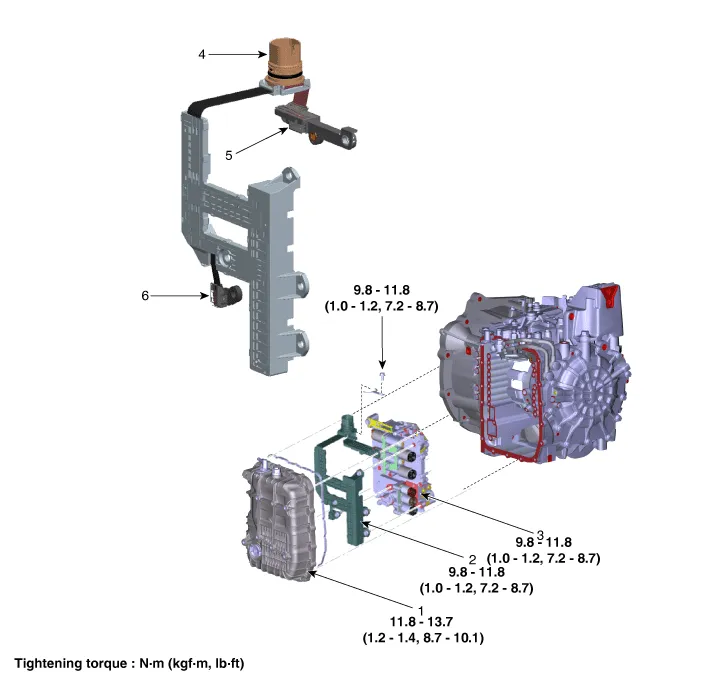

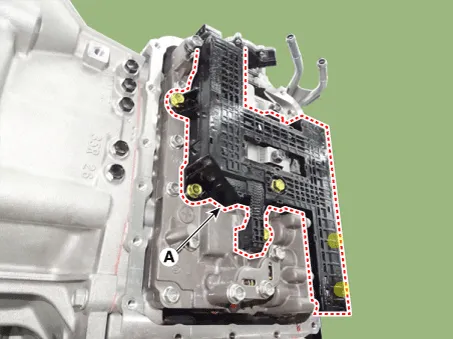

Components and components location

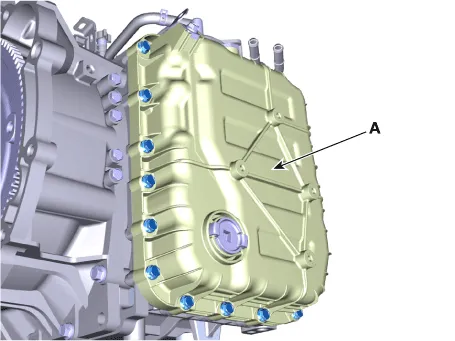

1. Valve Body Cover

|

4. Main Connector

|

2. Main Harness

|

5. Speed Sensor Connector

|

3. Valve Body

|

6. Oil Temperature Sensor

|

Repair procedures

| 1. |

The automatic transaxle system can be more quickly diagnosed for troubles

by using the vehicle diagnostic system (KDS). (Refer to "DTC guide")

KDS provides the following information.

| (1) |

Self diagnosis : Inspects and displays diagnostic trouble code

(DTC)

|

| (2) |

Sensor data : Checks the system input/output value status

|

| (3) |

Forced operation : Checks the system operating status

|

| (4) |

Additional function : Controls system options, zero point adjustment

and other functions

|

|

| 1. |

Check the resistance by using the KDS.

Item

|

Specification

|

Temp.[(°C)°F] / Resistance (kΩ)

|

(-40)-40 / 48.1

|

(-20)-4.0 / 15.6

|

(0)32.0 / 5.88

|

(20)68.0 / 2.51

|

(40)104.0 / 1.19

|

(60)140.0 / 0.61

|

(80)176.0 / 0.32

|

(100)212.0 / 0.18

|

(120)248.0 / 0.10

|

(140)284.0 / 0.06

|

(150)302.0 / 0.05

|

|

| • |

Automatic transaxle is composed of delicate components. Be careful

not to cause any damage on the component in the course of assembly

and disassembly.

|

| • |

Maintain clean condition so that foreign substance does not get

into the automatic transaxle.

|

| • |

Use a coated apron, latex gloves, and stainless tray to prevent

foreign substance from getting into the transaxle.

|

|

| 1. |

Remove the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

|

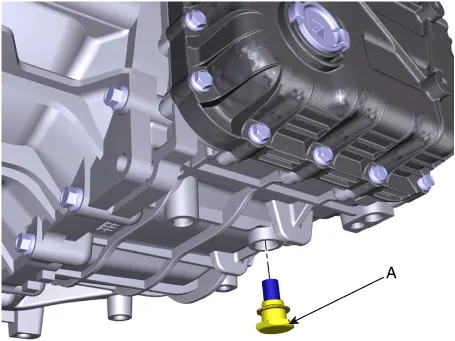

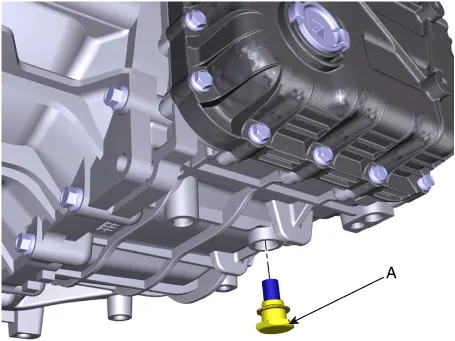

| 2. |

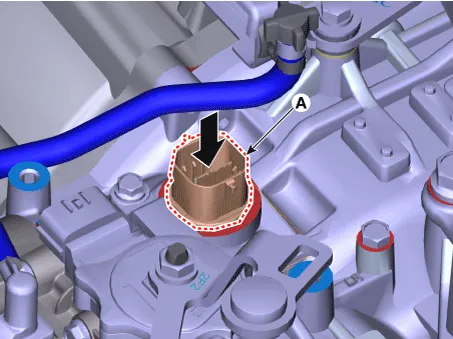

Remove the ATF drain plug (A), allow the fluid to drain out and then

reinstall the drain plug.

|

Tightening torque:

33.3 - 43.1 N·m (3.4 - 4.4 kgf·m, 24.6 - 31.8 lb·ft)

|

| •

|

The existing ATF drain plug gasket must be replaced with

a new one. (Do not reuse it.)

|

| •

|

Automatic transaxle fluid (ATF) can be reused. Collect

it using a clean 10-liter beaker.

|

|

|

| 3. |

Remove the air duct and air cleaner assembly.

(Refer to Engine Mechanical System - "Air cleaner")

|

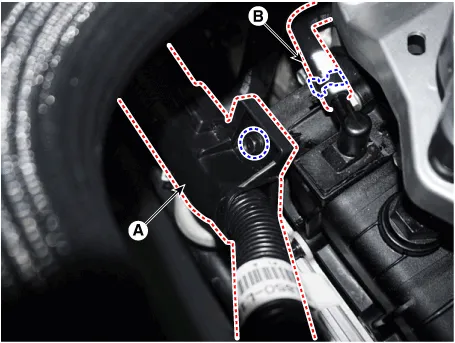

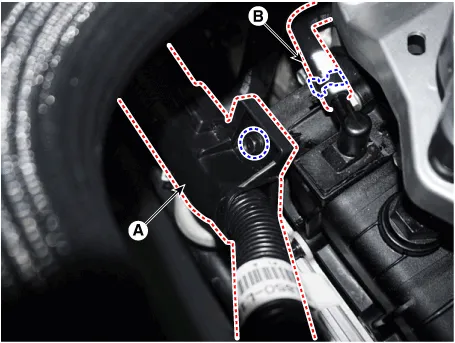

| 4. |

Remove the wiring bracket (A) and the air breather hose (B).

|

Tightening torque:

9.8 - 11.8 N·m (1.0 - 1.2 kgf·m, 7.2 - 8.7 lb·ft)

|

|

| 5. |

Disconnect the hose (A) after removing the automatic transaxle fluid

cooler hose clamp.

|

| 6. |

Lift the vehicle after loosening valve body cover upper bolts.

|

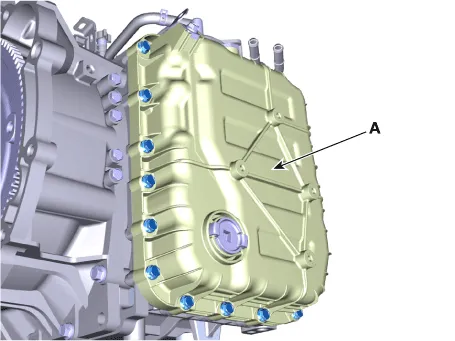

| 7. |

Remove the valve body cover (A) by loosening bolts.

|

Tightening torque:

11.8 - 13.7 N·m (1.2 - 1.4 kgf·m, 8.7 - 10.1 lb·ft)

|

|

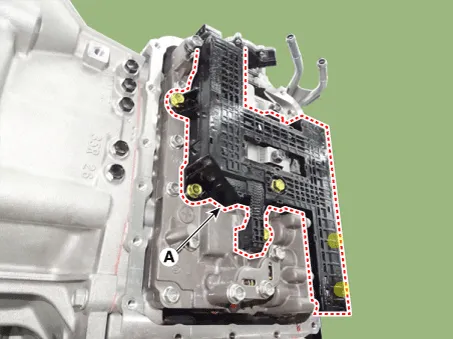

| 8. |

Remove the main harness (A) after removing the bolts.

|

Tightening torque:

9.8 - 11.8 N·m (1.0 - 1.2 kgf·m, 7.2 - 8.7 lb·ft)

|

|

| 9. |

Remove the valve body assembly (A) after loosening the bolts.

|

Tightening torque:

9.8 - 11.8 N·m (1.0 - 1.2 kgf·m, 7.2 - 8.7 lb·ft)

|

|

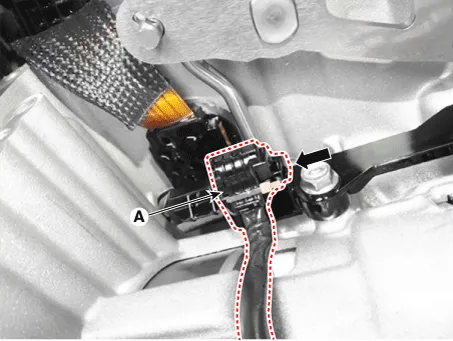

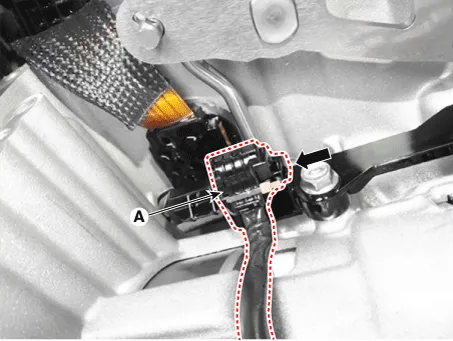

| 10. |

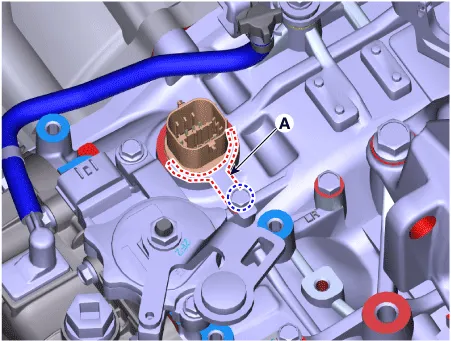

Disconnect the speed sensor connector (A).

|

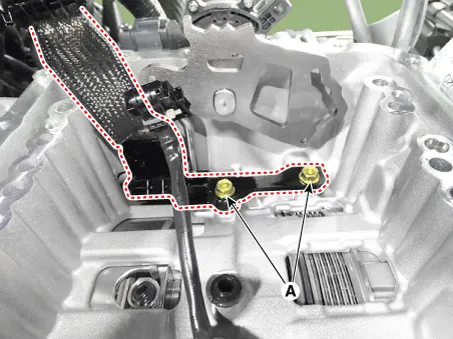

| 11. |

Loosen the main harness bolt (A).

|

Tightening torque :

9.8 - 11.8 N·m (1.0 - 1.2 kgf·m, 7.2 - 8.7 lb·ft)

|

|

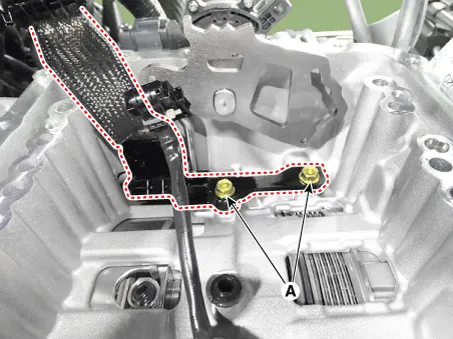

| 12. |

Disconnect the solenoid valve connector (A).

|

| 13. |

Remove the solenoid valve connector mounting clip (A).

|

Tightening torque:

9.8 - 11.8 N·m (1.0 - 1.2 kgf·m, 7.2 - 8.7 lb·ft)

|

|

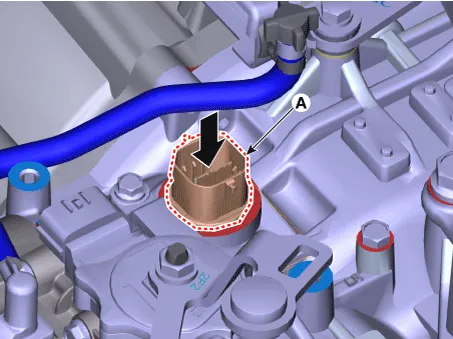

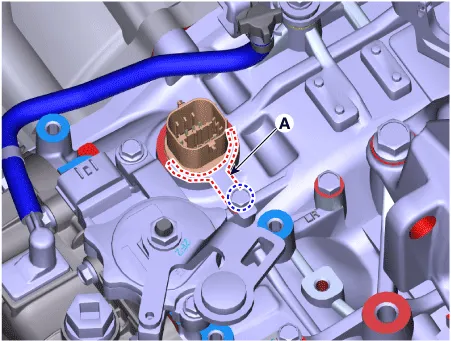

| 14. |

Remove the solenoid valve connector (A) by pushing down from the transaxle.

|

| 1. |

Install in the reverse order of removal.

| •

|

Before installing the connector, apply the ATF to the

O-ring.

|

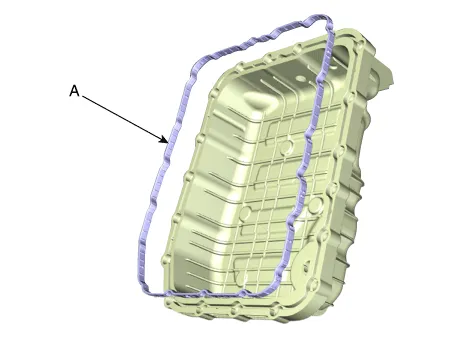

| •

|

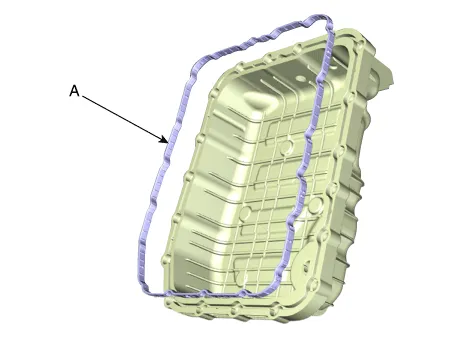

The existing valve body cover gasket (A) must be replaced

with a new one. (Do not reuse it.)

|

| •

|

Check fluid level, after filling the automatic transaxle

with fluid.

(Refer to Hydraulic System - "Fluid")

|

| •

|

After installing, check for leakage of coolant or fluid

from hose connection during engine start.

|

|

|

Description and operation

Description

The module receives and processes signals from various sensors and implements

a wide range of transaxle controls to ensure optimal driving conditions for the

driver.

Specifications

Specification

Item

Specification

Type

Hall effect sensor

Output voltage (V)

High : 1.

Other information:

Repair procedures

Removal

When removing with a flat-tip screwdriver or remover, wrap protective

tape around the tools to prevent damage to components.

1.

Components and components location

Components Location

1. Mode control actuator

Description and operation

Description

The mode control actuator is located at the heater unit.

It adjusts the position of the mode door by operating the mode control actuator

based on the signal of the A/C co