Kia Optima DL3: Engine And Transaxle Assembly / Engine Mounting

Components and components location

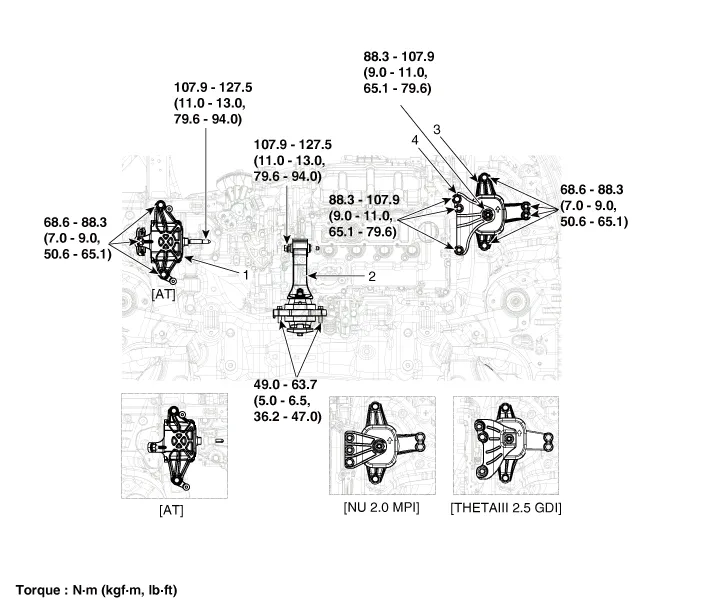

| Components |

| 1. Transaxle mounting bracket

2. Roll rod bracket |

3. Engine mounting bracket

4. Engine mounting support bracket |

Repair procedures

| Removal and Installation |

Engine Mounting Bracket

| 1. |

Remove the engine room under cover. (Refer to Engine and Transaxle Assembly - "Engine Room Under Cover") |

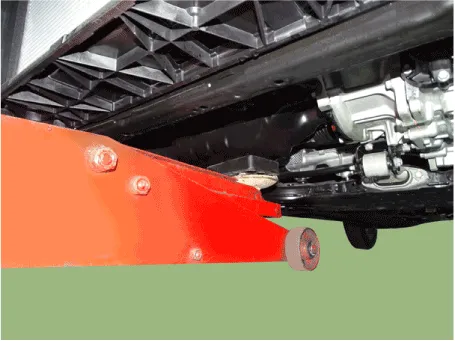

| 2. |

Install the jack under the edge of lower oil pan to support the engine.

|

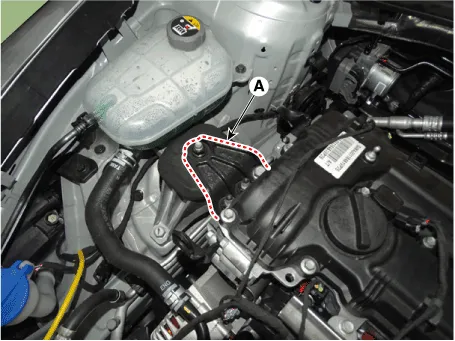

| 3. |

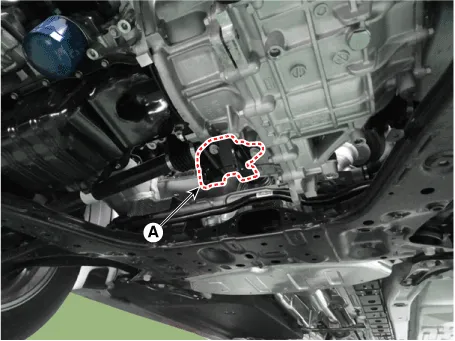

Remove the engine mounting support bracket (A).

|

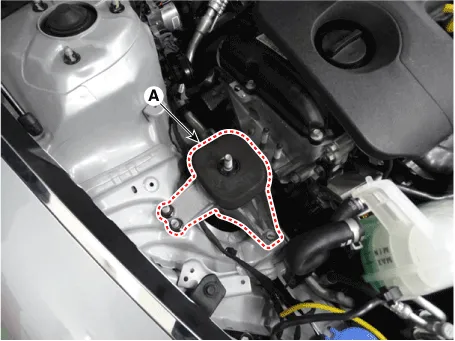

| 4. |

Remove the engine mounting bracket (A).

|

| 5. |

Install in the reverse order of removal. |

Transaxle mounting bracket

| 1. |

Disconnect the battery negative terminal. |

| 2. |

Remove the engine room under cover. (Refer to Engine and Transaxle Assembly - "Engine Room Under Cover") |

| 3. |

Remove the air cleaner assembly. (Refer to Intake and Exhaust System - "Air Cleaner") |

| 4. |

Remove the engine control module (ECM). (Refer to Engine / Fuel System - "Engine Control Module (ECM)") |

| 5. |

Remove the battery and battery tray. (Refer to Engine Electrical System - "Battery") |

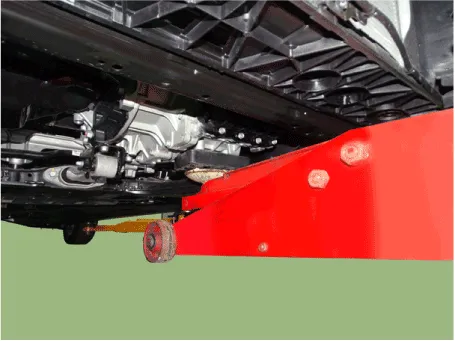

| 6. |

Install jack under the transaxle to support it.

|

| 7. |

Remove the transaxle mounting side pannel packing (A).

|

| 8. |

Remove the transaxle support bracket mounting bolt (A).

|

| 9. |

Remove the transaxle mounting bracket (A).

|

| 10. |

Install in the reverse order of removal. |

Roll Rod Bracket

| 1. |

Remove the engine room under cover. (Refer to Engine and Transaxle Assembly - "Engine Room Under Cover") |

| 2. |

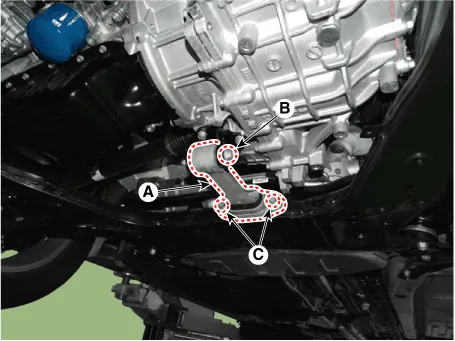

Remove the roll rod bracket (A).

|

| 3. |

Remove the roll rod suport bracket (A).

|

| 4. |

Install in the reverse order of removal. |

Repair procedures Removal and Installation Engine Room Under Cover 1. Remove the engine room under cover (A). Tightening torque: 7.

Repair procedures Removal • Use fender covers to avoid damaging painted surfaces.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Rear Combination Lamp

Components and components location Component Location 1. Tail lamp 2. Stop lamp 3. Tail/Stop lamp 4. Back up lamp 5. Turn signal lamp Schematic diagrams Connector and Terminal Function [A Type] Pin Function Center Ou

Kia Optima DL3 2019-2026 Service and Repair Manual: Intake Actuator

Components and components location Components Location 1. Intake actuator Description and operation Description The intake actuator is located at the blower unit. It regulates the intake door by a signal from the control unit.

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Steering System

- Engine Control / Fuel System

- Headlamps

- New on site

- Most important about car