Kia Optima DL3: Brake System / Front Brake Disc

Components and components location

| Components |

| 1. Front Brake Caliper 2. Front Brake Disc |

3. Front Axle |

Repair procedures

| Removal |

| 1. |

Disconnect the (-) battery terminal. |

| 2. |

Remove the front wheel and tire. (Refer to Suspension System - "Wheel") |

| 3. |

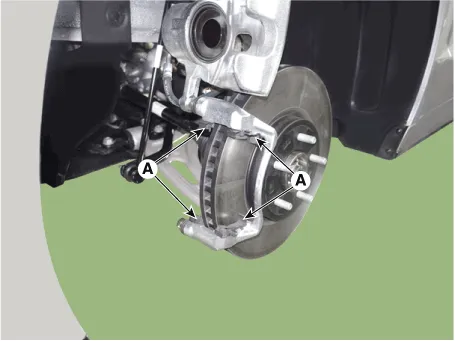

Loosen the guide rod bolt and then pivot the caliper body (A) up out of the way.

|

| 4. |

Remove the brake pad (A).

|

| 5. |

Remove the pad retainer (A).

|

| 6. |

Remove the caliper carrier (A) by loosening the caliper mouniting bolts.

|

| 7. |

Remove the front brake disc (A) by loosening the screws.

|

| Inspection |

Front Brake Disc Thickness Check

| 1. |

Check the brake disc for damage and cracks. |

| 2. |

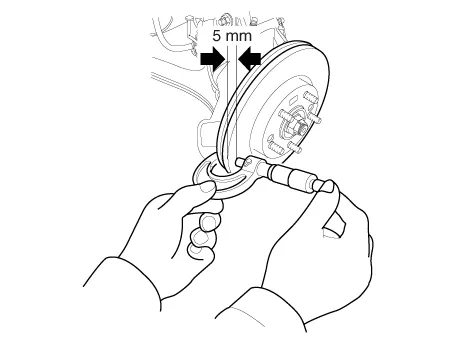

Remove all rust and contamination from the surface, and measure the disc thickness at 8 points, at least, of same distance (5mm) from the brake disc outer circle.

|

| 3. |

If wear exceeds the limit, replace the discs and pad assembly left and right of the vehicle. |

Front Brake Disc Runout Check

| 1. |

Place a dial gauge about 5mm (0.20 in) from the outer circumference of the brake disc, and measure the runout of the disc.

|

| 2. |

If the runout of the brake disc exceeds the limit specification, replace the disc, and then measure the runout again. |

| 3. |

If the runout does not exceed the limit specification, install the brake disc after turning it 180° and then check the runout of the brake disc again. |

| Installation |

| 1. |

Install in the reverse order of removal. |

| 2. |

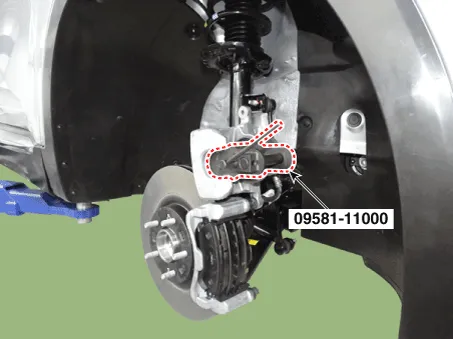

Use a SST (09581-11000) when installing the brake caliper assembly.

|

| 3. |

After installation, bleed the brake system. (Refer to Brake System - "Brake Bleeding Prcoedures") |

| 4. |

Check the brake oil leakage and pedal operating condition. |

Components and components location Components 1. Caliper body 2. Caliper carrier 3. Pad inner shim 4. Brake pad 5.

Components and components location Components [EPB Apply] 1. EPB Actuator 2. Caliper body 3. Caliper carrier 4.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Smart Key System

Specifications Specifications Smart Key Unit Items Specification Rated voltage DC 12 V Operation voltage DC 9 - 16 V Operation temperature -40 to 185°F (-40 to 85°C) RF Receiver Items

Kia Optima DL3 2019-2026 Service and Repair Manual: Evaporator Temperature Sensor

Description and operation Description The evaporator temperature sensor will detect the evaporator core temperature and interrupt compressor relay power in order to prevent evaporator from freezing by excessive cooling. The evaporator temperature sensor has the Negative Temperature Coefficient (NTC).

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Engine Control / Fuel System

- External Amp

- Suspension System

- New on site

- Most important about car