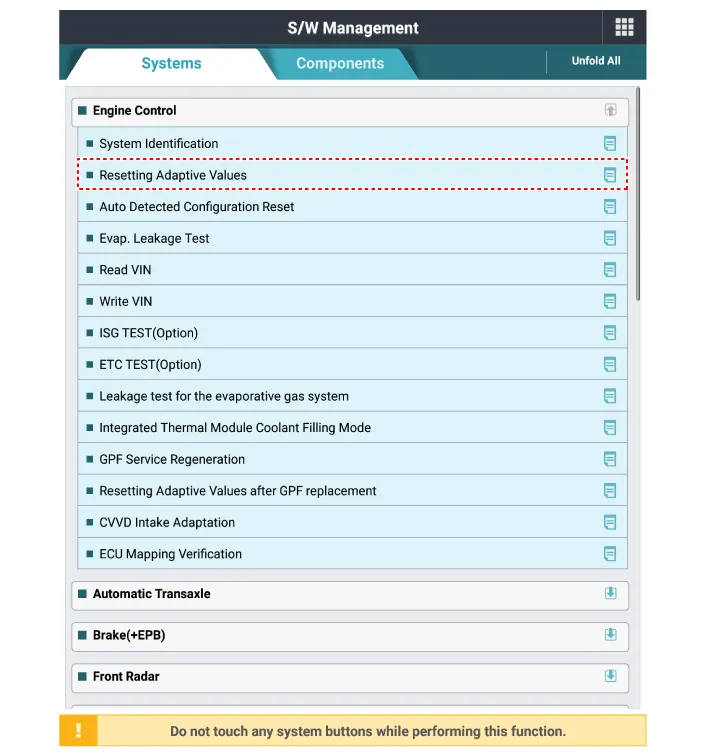

Kia Optima DL3: Engine Control System / Heated Oxygen Sensor (HO2S)

Description and operation

| Description |

| • |

Heated Oxygen Sensor (HO2S), consisting of zirconium and alumina, is installed on both upstream and downstream of the Manifold Catalytic Converter (MCC) to detect the air/fuel ratio and send it to the ECM. |

| • |

In order that this sensor operates properly, the temperature of the sensor tip must be higher than 370°C (698°F). For this reason, a heater controlled by the ECM duty signal, is built into the sensor. When the exhaust gas temperature is lower than the specified value, the heater warms the sensor tip. |

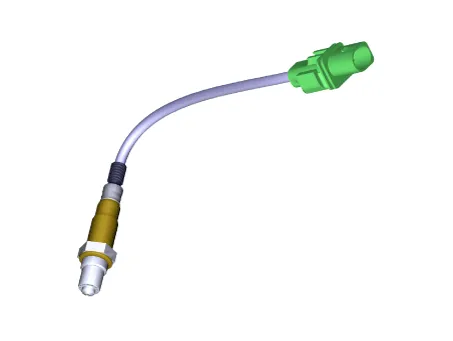

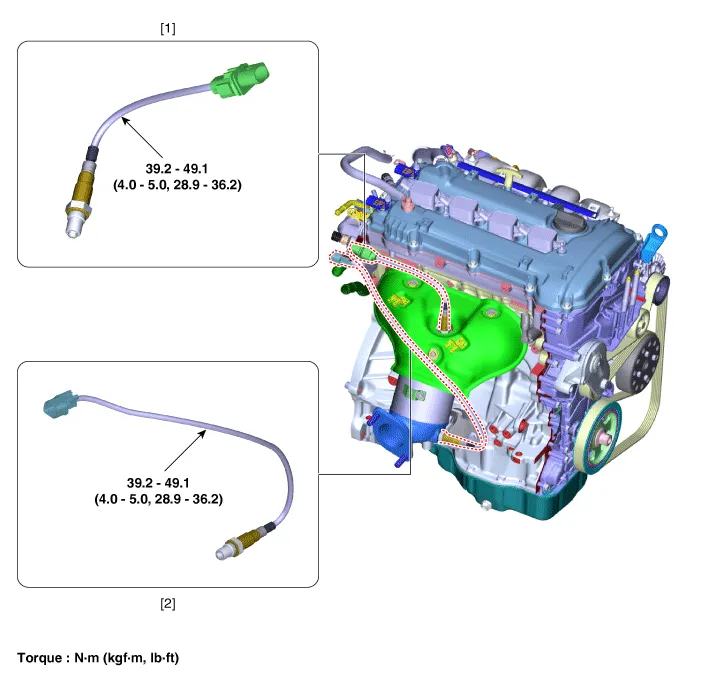

[Front Heated Oxygen Sensor]

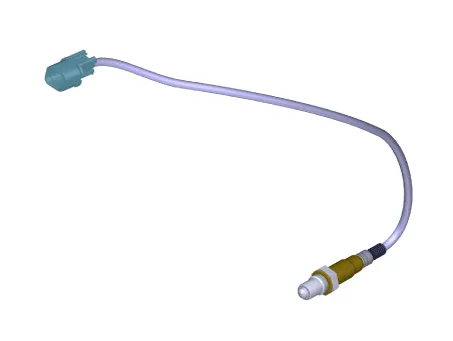

[Rear Heated Oxygen Sensor]

Components and components location

| Components Location |

| 1. Front Heated Oxygen Sensor

|

2. Rear Heated Oxygen Sensor

|

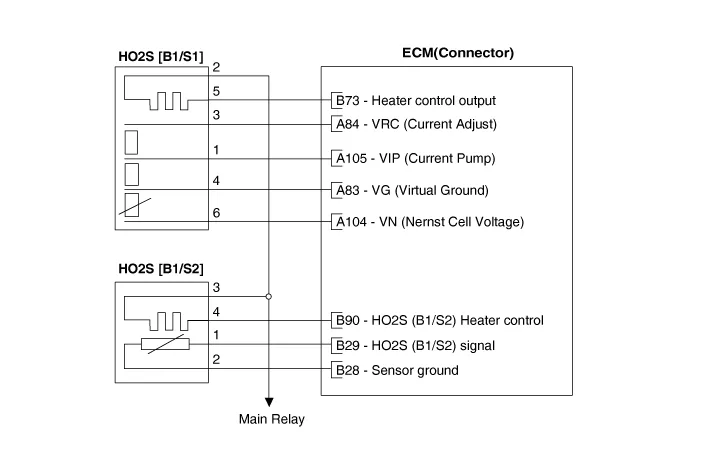

Schematic diagrams

| Circuit Diagram |

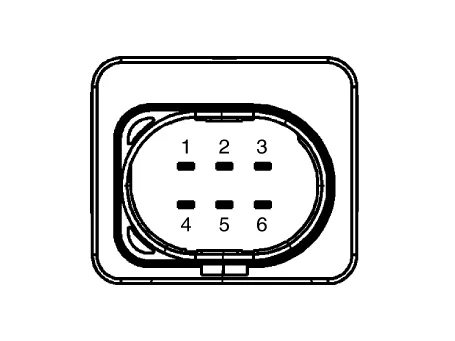

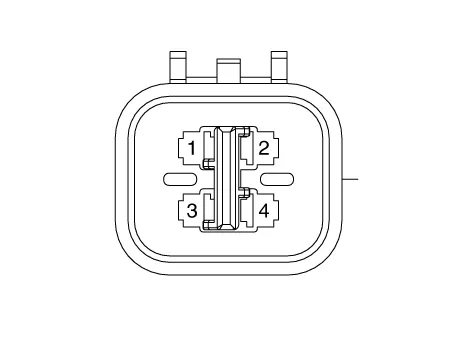

Harness Connector

[Front Heated Oxygen Sensor]

[Rear Heated Oxygen Sensor]

Repair procedures

| Inspection |

| 1. |

The engine control system can be more quickly diagnosed for troubles by using the vehicle diagnostic system (KDS). (Refer to "DTC guide") KDS provides the following information.

|

| Component Inspection |

| 1. |

Check signal waveform of HO2S using a KDS.

|

| Removal |

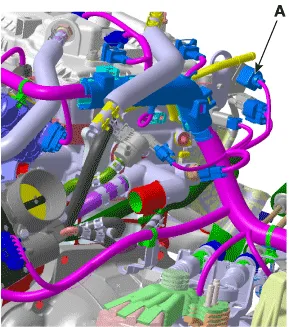

| [Front Heated Oxygen Sensor] |

| 1. |

Disconnect the negative battery terminal. |

| 2. |

Disconnect the connector (A).

|

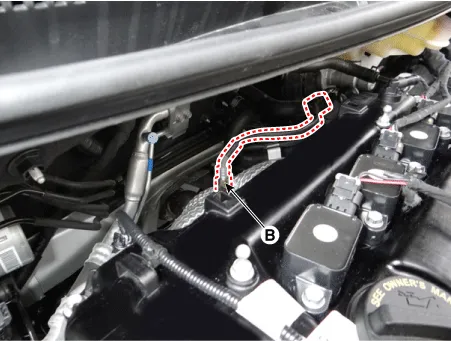

| 3. |

Remove the heated oxygen sensor (B) by using the SST (09392-1Y100)

|

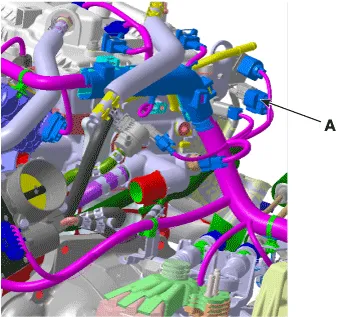

| [Rear Heated Oxygen Sensor] |

| 1. |

Disconnect the negative battery terminal. |

| 2. |

Disconnect the heated oxygen sensor connector (A).

|

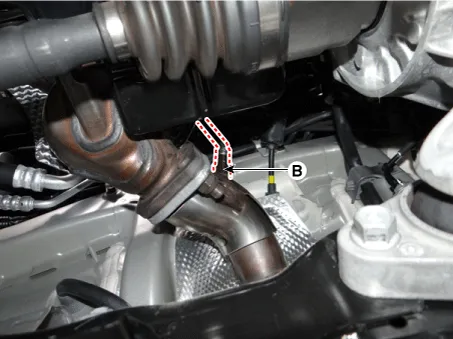

| 3. |

Remove the heated oxygen sensor (B) by using the SST (09392-1Y100)

|

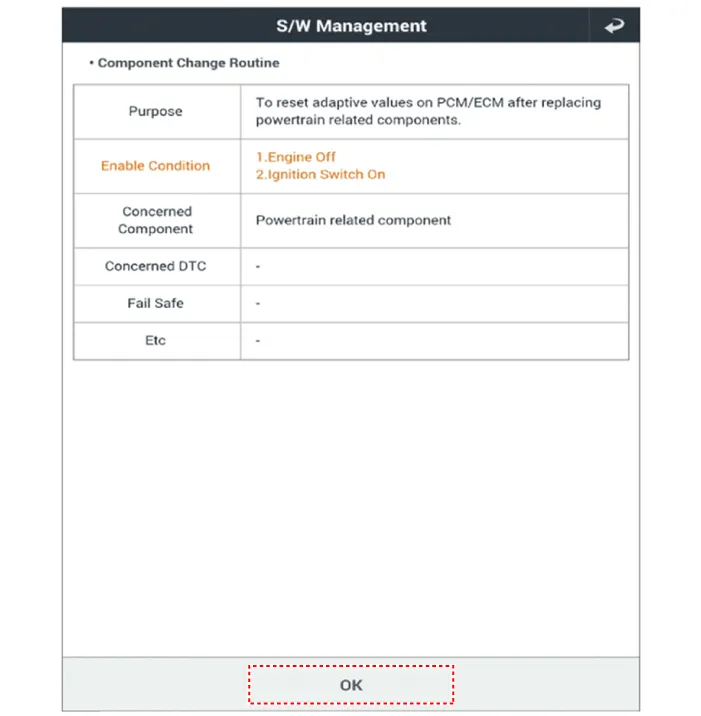

| Installation |

|

| 1. |

Install in the reverse order of removal. |

| 2. |

Reset the ECM adaptive value after replacing the heated oxygen sensor.

|

Specifications Specification Item Specification Capacitance (pF) 850 - 1,150 Description and operation Description • Knocking is a condition characterized by undesirable vibration and noise and can cause engine damage.

Specifications Specification Accelerator Output Voltage (V) [Vref = 5.0V] Position APS1 APS2 C.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: High Mounted Stop Lamp

Repair procedures Removal 1. Disconnect the negative battery terminal. 2. Remove the roof trim assembly. (Refer to Body - "Roof Trim Assembly") 3. Disconnect the high mounted stop lamp connector (A).

Kia Optima DL3 2019-2026 Service and Repair Manual: Multifunction Switch

Specifications Specifications Items Specifications Rated voltage Front fog lamp switch 5 V Lighting Auto lighting Dimmer & Passing Turn signal lamp Wiper Was

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Steering System

- Engine Control Module (ECM)

- Rear Bumper Assembly

- New on site

- Most important about car