Kia Optima DL3: Power Train / Cooling System

Repair procedures

Radiator hoses

| 1. |

Check radiator hoses for the following:

|

Coolant level

| 1. |

Check the coolant level in the coolant reservoir. Make sure it is between

the "F" mark and "L" mark.

|

| 2. |

If the coolant level in the coolant reservoir is at or below the "L"

mark, add coolant to bring it between the "L" and "F" marks, then inspect

the cooling system for leaks.

|

Coolant quality

| 1. |

Remove the radiator cap.

|

| 2. |

Check if there are any excessive deposits of rust or scale around the

radiator cap sub-assembly and radiator filler hole. Also, the coolant should

be free of oil.

If excessively dirty, clean the coolant passage and replace the coolant.

|

| 3. |

Install the radiator cap.

|

|

Never remove the reservoir tank cap when the engine is hot. Serious scalding

could be caused by hot fluid under high pressure escaping from the radiator.

|

|

When pouring engine coolant, be sure to shut the relay box lid and not

to let coolant spill on the electrical parts or the paint. If any coolant

spills, rinse it off immediately.

|

| 1. |

Make sure the engine and radiator are cool to the touch.

|

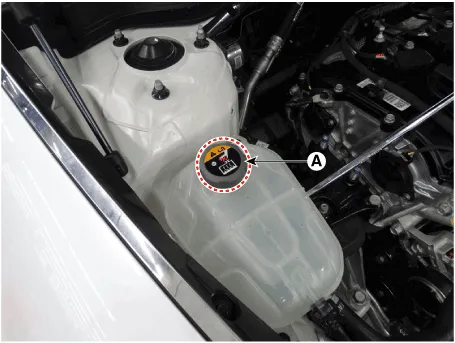

| 2. |

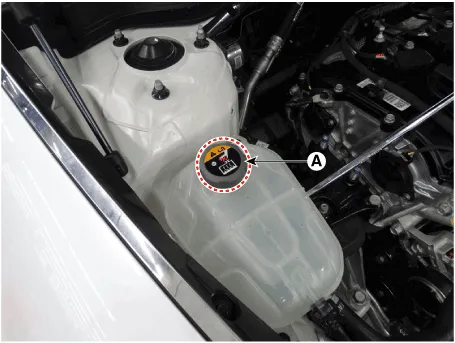

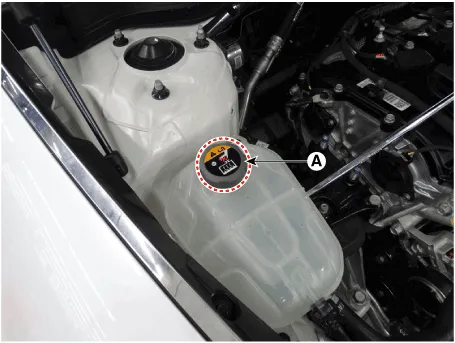

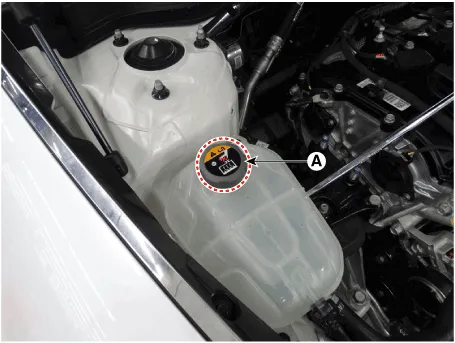

Remove the reservoir tank cap (A).

|

| 3. |

Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - “Engine Room Under Cover”)

|

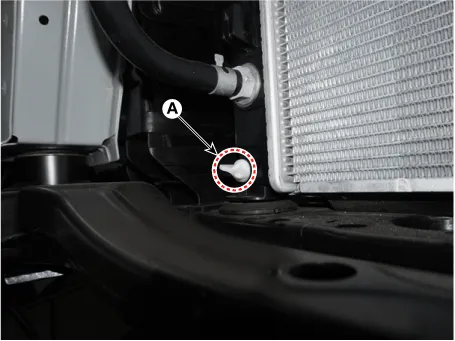

| 4. |

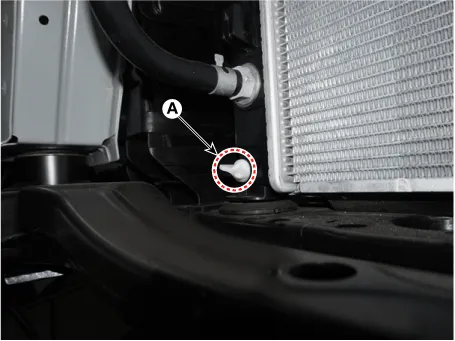

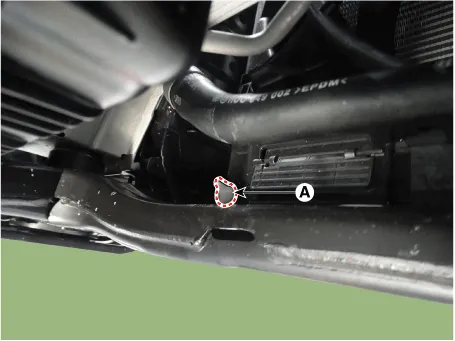

Loosen the drain plug (A) and drain the coolant.

|

| 5. |

Tighten the radiator drain plug securely.

|

| 6. |

Clean the reservoir tank.

|

| 7. |

Fill the reservoir tank with coolant and tighten the reservoir tank cap.

|

To most effectively bleed the air, pour the water slowly and

press on the upper/lower radiator hoses.

|

|

| 8. |

Start the engine and allow to come to normal operating temperature. Wait

for the cooling fans to turn on several times. Accelerate the engine to

aid in purging trapped air. Shut engine off.

|

| 9. |

Wait until the engine is cool.

|

| 10. |

Repeat step 1 to 9 until the drained water runs clear.

|

| 11. |

Fill fluid mixture with coolant and water (55 - 60%) (except for North

America, Europe and China: 45 - 50%) slowly through the reservoir tank.

Push the upper/lower hoses of the radiator so as bleed air easily.

| •

|

Use only genuine antifreeze/coolant.

|

| •

|

For best corrosion protection, the coolant concentration

must be maintained year-round at 55% (except for North America,

Europe and China: 45%) minimum.

Coolant concentrations less than 55% (except for North

America, Europe and China: 45%) may not provide sufficient

protection against corrosion or freezing.

|

| •

|

Coolant concentrations greater then 60% will impair cooling

efficiency and are not recommended.

|

|

| •

|

Do not mix different brands of antifreeze / coolants.

|

| •

|

Do not use additional rust inhibitors or antirust products;

they may not be compatible with the coolant.

|

|

|

| 12. |

Start the engine and run until coolant circulates. When the cooling fan

operates and coolant circulates, refill coolant through the reservoir tank.

|

| 13. |

Repeat step 12 until the cooling fan 3 - 5 times and bleed air sufficiently

out of the cooling system.

|

| 14. |

Fill the reservoir tank to the "MAX" (or "FULL") line with coolant and

tighten the reservoir tank cap.

|

| 15. |

Run the vehicle under idle until the cooling fan operates 2-3 times.

|

| 16. |

Stop the engine and wait coolant gets cool.

|

| 17. |

Repeat step 11 to 16 until the coolant level doesn't fall any more, bleed

air out of the cooling system.

|

It takes time to bleed out all the air in the cooling system.

Refill coolant when coolant gets cool completely, then recheck the

coolant level in the reservoir tank for 2-3 days after replacing

coolant.

|

|

Coolant capacity

Approx. 6.3 L (1.66 U.S.gal., 6.66 U.S.qt., 5.54 lmp.qt.)

|

|

| • |

Never remove the reservoir tank cap when the engine is hot. Otherwise,

serious scalding could be caused by hot fluid under high pressure

escaping from the radiator. Open the reservoir tank cap after engine

cools down sufficiently.

|

|

| • |

When changing coolant, Be careful not to spill coolant on the

belt, electrical devices, etc.

|

| • |

When changing engine coolant and conduct air bleeding, be sure

to follow the iIntegrated thermal management module (ITM) coolant

filling method.

|

|

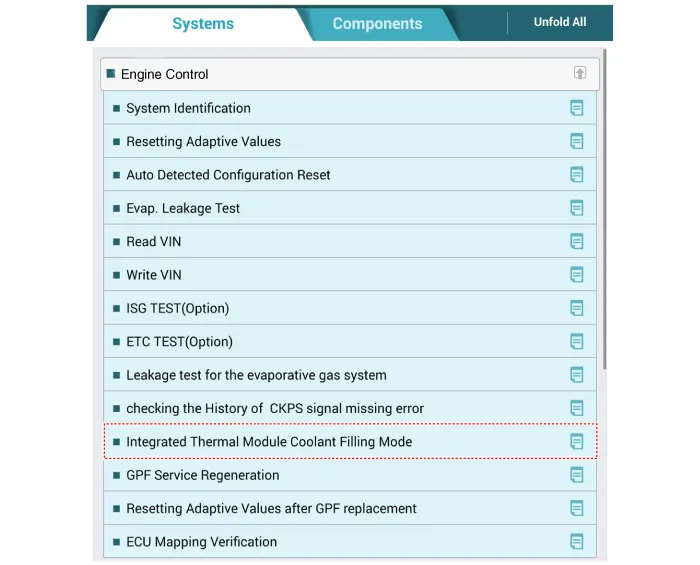

When KDS is available,

conduct coolant change and air bleeding following the below procedure.

| 1. |

When KDS is available, conduct coolant change and air bleeding following

the below procedure.

|

| 2. |

Remove the reservoir tank cap (A).

|

| 3. |

Remove the engine room under cover.

(Refer to Engine And Transaxle Assembly - "Engine Room Under Cover")

|

| 4. |

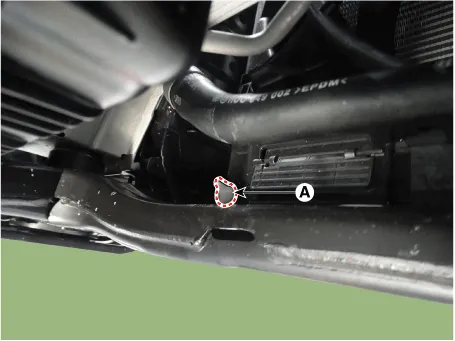

Drain engine coolant by loosening the drain plug (A).

|

| 5. |

After coolant drain is completed, retighten the drain plug.

|

| 6. |

Drain coolant in the reservoir tank and then clean reservoir tank.

|

| 7. |

Install the coolant refill tank on the radiator and then add the mixture

of anti-freeze and water (55 - 60%) (except for North America, Europe and

China: 45 - 50%)

|

Fill coolant as far as possible with engine and all power supplies

shut off.

|

|

Coolant capacity

Approx.8.2 L (2.2 U.S.gal., 8.7 U.S.qt., 7.2 lmp.qt.)

|

| •

|

Push the upper / lower hoses on the radiator so that

the air can get out easily.

|

| •

|

Use only genuine antifreeze/coolant.

|

| •

|

For best corrosion protection, the coolant concentration

must be maintained year-round at 55% (except for North America,

Europe and China: 45%) minimum.

Coolant concentrations less than 55% (except for North

America, Europe and China: 45%) may not provide sufficient

protection against corrosion or freezing.

|

| •

|

Coolant concentrations greater than 60% will impair cooling

efficiency and are not recommended.

|

| •

|

Do not mix different brands of antifreeze/coolants.

|

| •

|

Do not use the additional anti-rust additives.

|

|

|

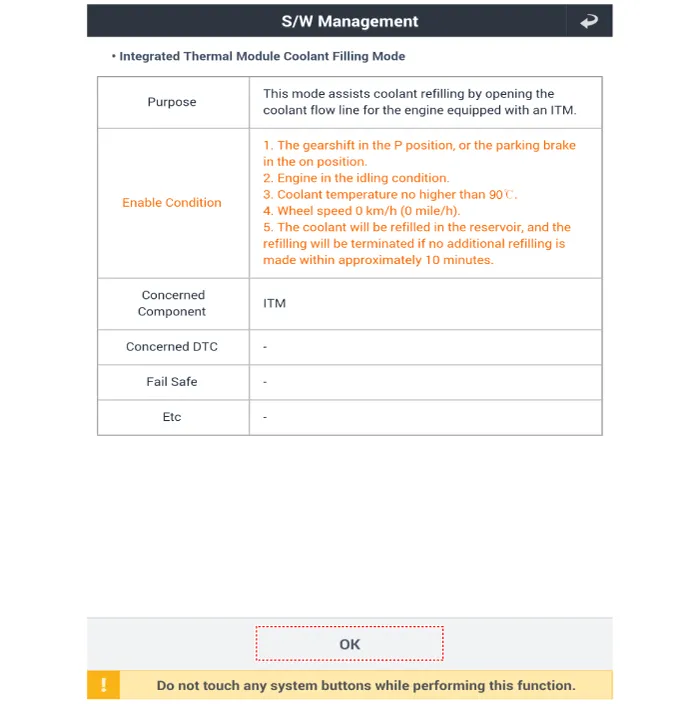

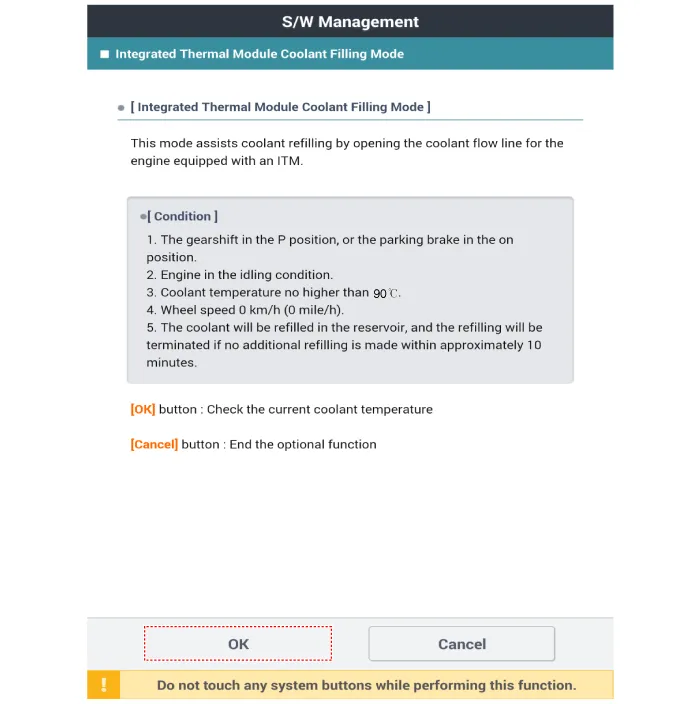

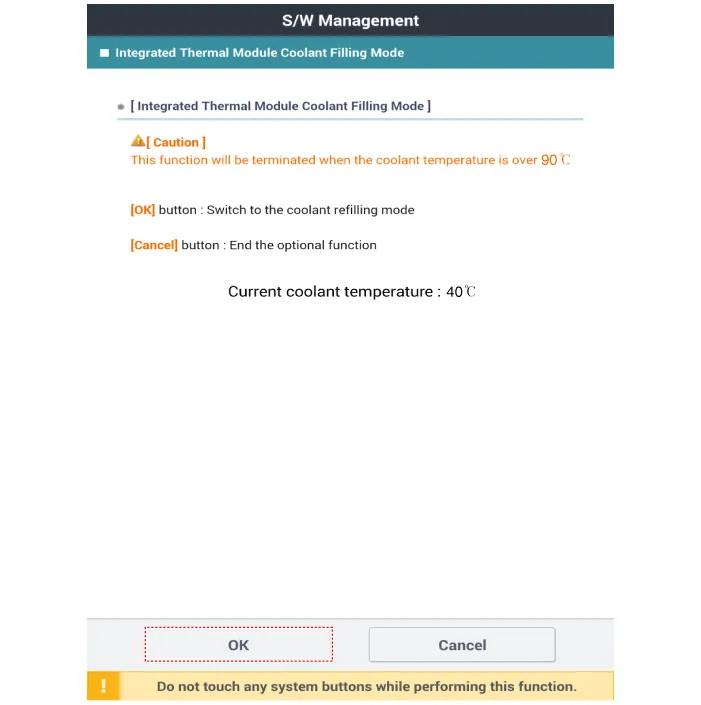

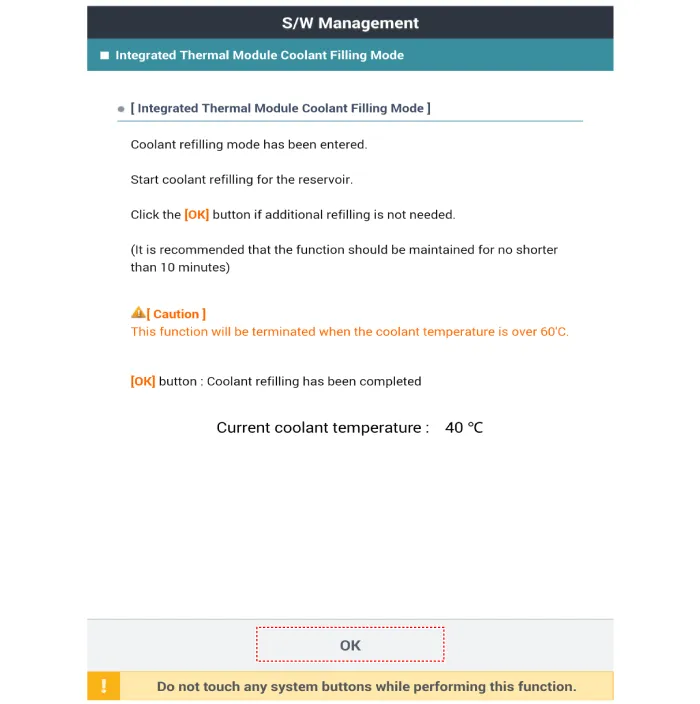

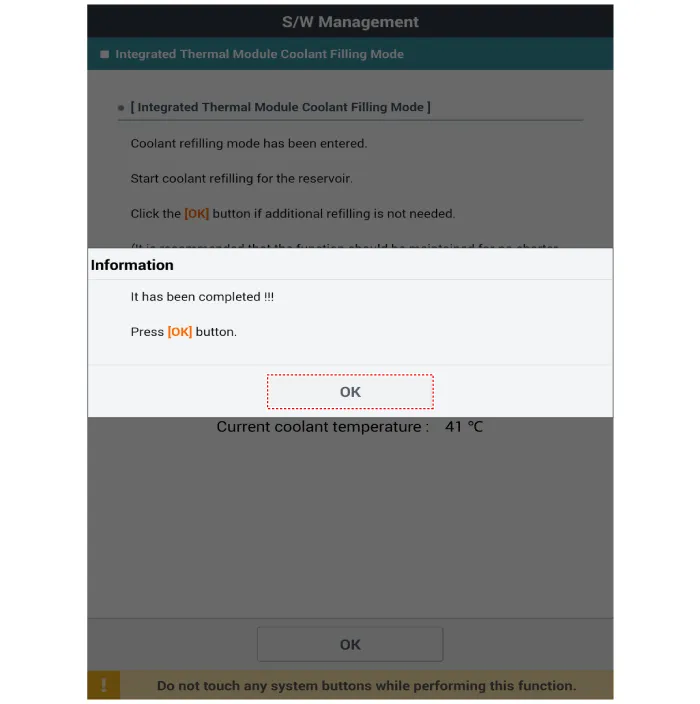

| 10. |

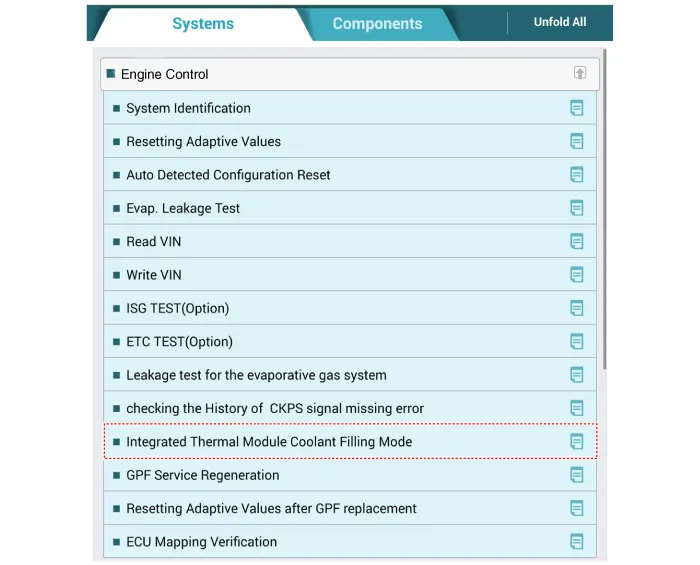

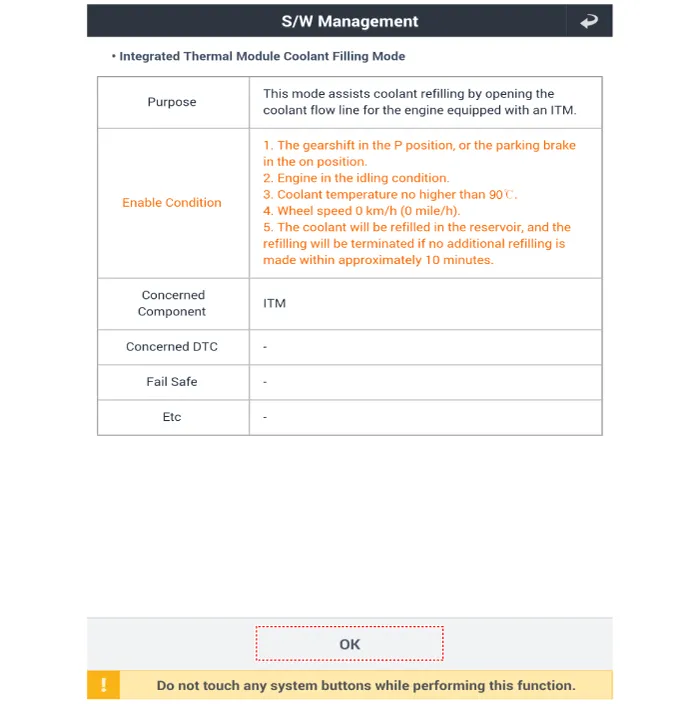

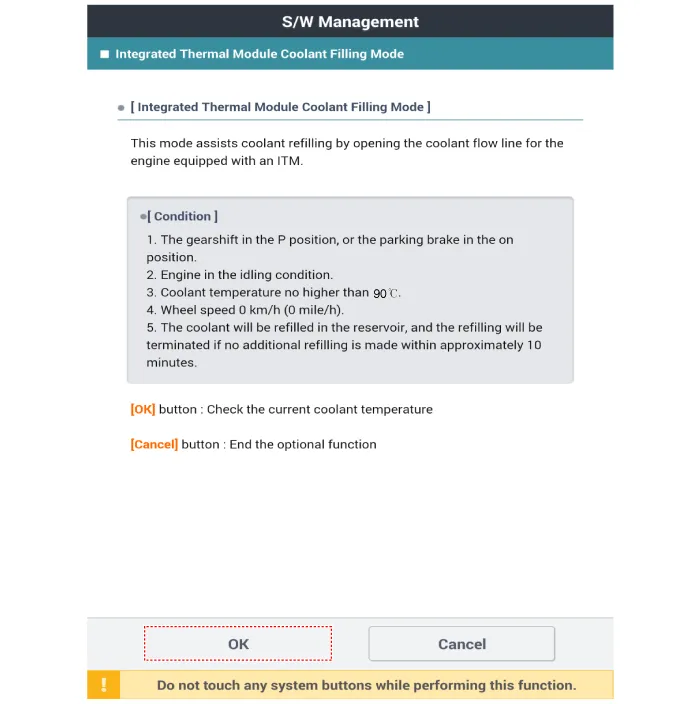

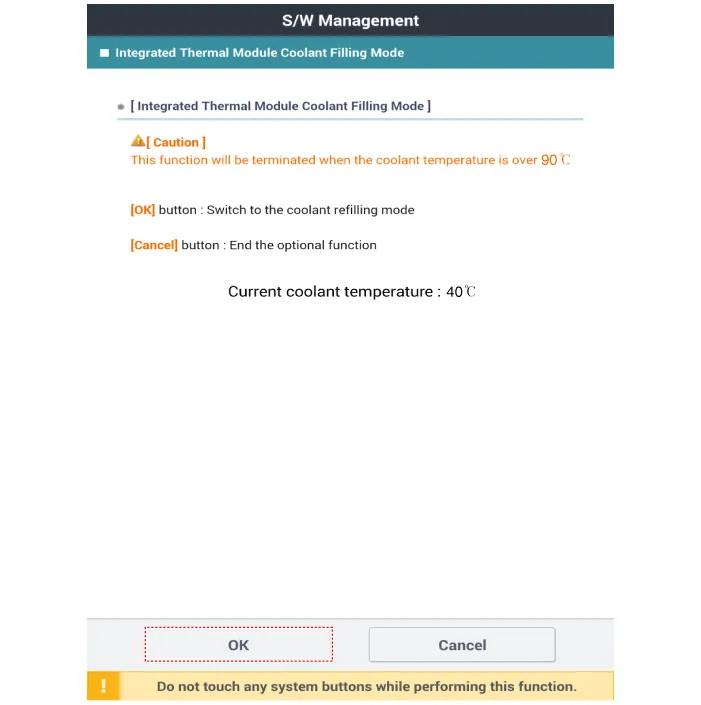

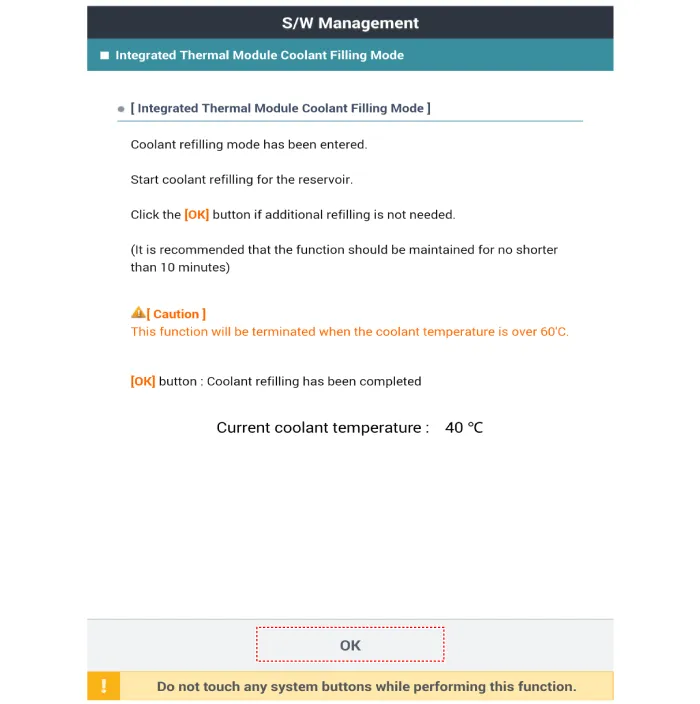

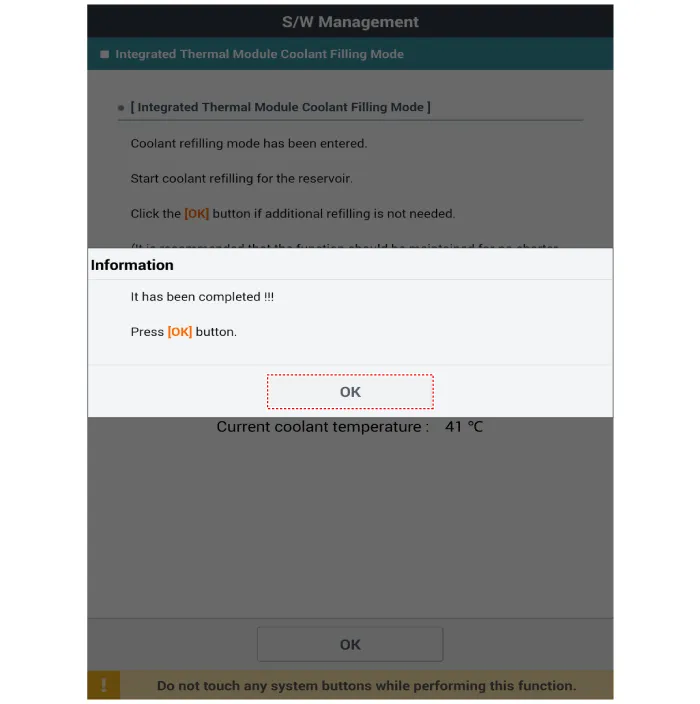

Select the "ITM coolant filling mode" in the Vehicle S/W Management.

|

| 11. |

Warm up the engine for 20 minutes after cooling fan operates 1 time.

|

| 12. |

After disconnecting the KDS, turn the ignition switch to OFF and then

restart engine.

|

| 13. |

Install the reservoir tank cap (A).

|

| 14. |

Add coolant if it is insufficient.

|

| 15. |

Install the engine room under cover.

(Refer to Engine And Transaxle Assembly - "Engine Room Under Cover")

|

When KDS is unavailable,

conduct coolant change and air bleeding following the below procedure.

| 1. |

Check that the engine and radiator cool down sufficiently.

|

| 2. |

Remove the reservoir tank cap (A).

|

| 3. |

Remove the engine room under cover.

(Refer to Engine And Transaxle Assembly - "Engine Room Under Cover")

|

| 4. |

Drain engine coolant by loosening the drain plug (A).

|

| 5. |

After coolant drain is completed, retighten the drain plug.

|

| 6. |

Drain coolant in the reservoir tank and then clean the reservoir tank.

|

| 7. |

Install the coolant refill tank on the radiator and then add the mixture

of anti-freeze and water (55 - 60%) (except for North America, Europe and

China: 45 - 50%)

|

Fill coolant as far as possible with engine and all power supplies

shut off.

|

|

Coolant capacity

Approx.8.2 L (2.2 U.S.gal., 8.7 U.S.qt., 7.2 lmp.qt.)

|

| •

|

Push the upper / lower hoses on the radiator so that

the air can get out easily.

|

| •

|

Use only genuine antifreeze/coolant.

|

| •

|

For best corrosion protection, the coolant concentration

must be maintained year-round at 55% (except for North America,

Europe and China: 45%) minimum.

Coolant concentrations less than 55% (except for North

America, Europe and China: 45%) may not provide sufficient

protection against corrosion or freezing.

|

| •

|

Coolant concentrations greater than 60% will impair cooling

efficiency and are not recommended.

|

| •

|

Do not mix different brands of antifreeze/coolants.

|

| •

|

Do not use the additional anti-rust additives.

|

|

|

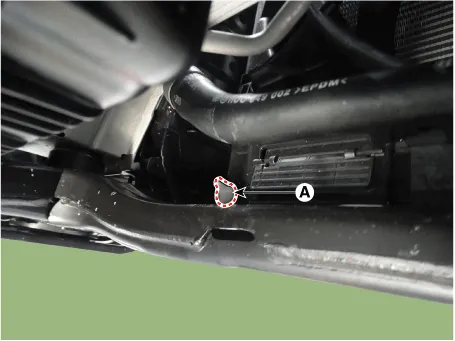

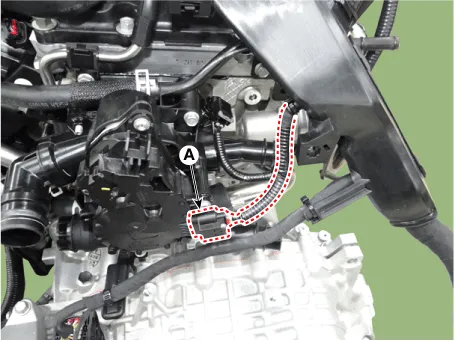

| 8. |

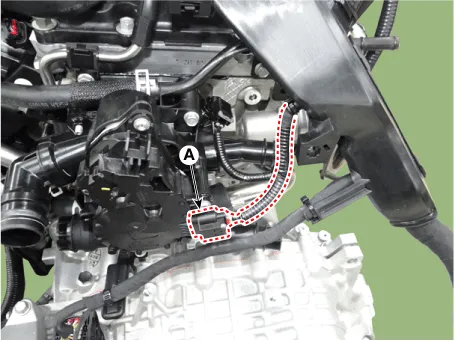

Disconnect the integrated thermal management module (ITM) connector (A).

| •

|

When disconnecting the integrated thermal management

module (ITM) connector, be sure to recheck that the engine

and all power supplies are shut off.

|

| •

|

Be careful not to allow the static electricity and any

other voltage are not applied to the integrated thermal

management module (ITM).

|

| •

|

Keep away the magnetic objects (Ex. magnet) from the

integrated thermal management module (ITM).

|

|

|

| 9. |

Start the engine.

|

Keep the engine with idling.

|

|

| 10. |

Warm up the engine for 20 minutes after cooling pan operates 1 time.

|

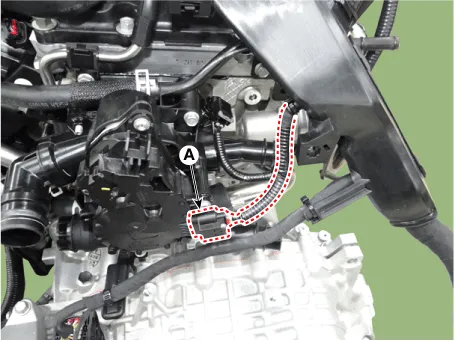

| 11. |

After turning the ignition switch to OFF, reconnect the integrated thermal

management module (ITM) connector (A).

| •

|

When reconnecting the integrated thermal management module

(ITM) connector, moisture and oil in the connector must

be completely removed and foreign materials should not enter.

|

| •

|

When replacing the integrated thermal management module

(ITM) connector, be sure to use the specified connector.

|

|

|

| 13. |

Check the integrated thermal management module (ITM) for operation by

operating sound.

|

Before/after starting up the engine, integrated thermal management

module (ITM) operating sound can be generated.

|

|

| 14. |

Repeat the engine ON/OFF and check the engine warning lamp OFF.

| (1) |

Wait for 5 seconds with engine ON and then turn OFF the engine.

|

| (2) |

Repeat the step (1) 3 times.

|

| (3) |

Check the engine warning lamp OFF when engine is turned ON fourthly.

|

|

| 15. |

Drive a vehicle until cooling fan operates and check the remaining amount

of coolant in reservoir tank while engine is hot.

|

| 16. |

Add coolant if it is insufficient.

|

| 17. |

Install the engine room under cover.

(Refer to Engine And Transaxle Assembly - "Engine Room Under Cover")

|

Repair procedures

Inspection

[NU 2.0 MPI]

Battery Voltage and

Status

Check the battery voltage and status by using a battery tester.

Repair procedures

Inspection

1.

Check belt for maintenance and abnormal wear of V-ribbed part. Replace

if necessary.

•

Do not bend, twist or turn the drive belt inside out.

Other information:

Repair procedures

Removal

When removing with a flat-tip screwdriver or remover, wrap protective

tape around the tools to prevent damage to components.

1.

Components and components location

Component Location

1. Heater unit assembly

Compoents

1. Mode control actuator

2. Temperature control actuator [LH]

3. PTC Heater dummy

4.