Kia Optima DL3: Crash Pad / Glove Box

Components and components location

| Component Location |

| 1. Glove box |

Repair procedures

| Replacement |

|

| 1. |

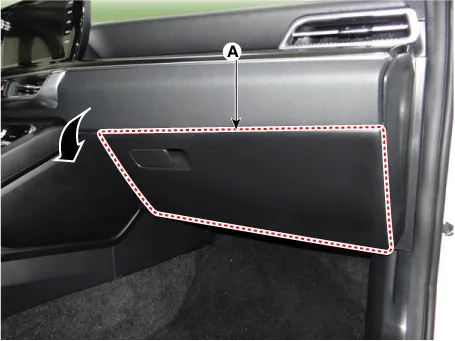

Open the glove box (A) in the direction of the arrow.

|

| 2. |

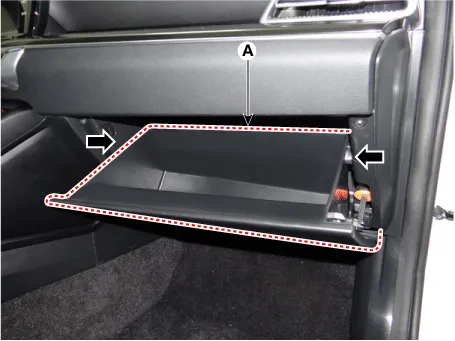

Separate the air damper (A) from the glove box.

|

| 3. |

Press both sides inwards to open the glove box (A) downwards.

|

| 4. |

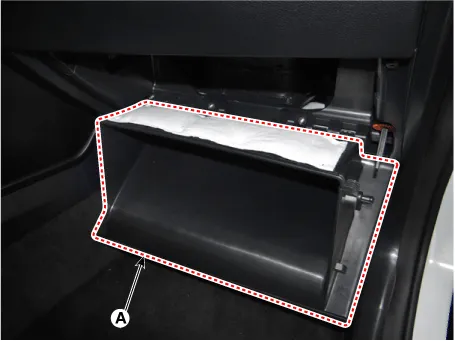

Remove the glove box (A).

|

| 5. |

To install, reverse removal procedure. |

Components and components location Component Location 1. Crash pad garnish [LH] 2. Crash pad garnish [RH] 3. Crash pad center garnish Repair procedures Replacement [Crash pad center garnish] • When removing with a flat-tip screwdriver or remover, wrap protective tape around the tools to prevent damage to components.

Repair procedures Replacement • When removing with a flat-tip screwdriver or remover, wrap protective tape around the tools to prevent damage to components.

Other information:

Kia Optima DL3 2019-2026 Service and Repair Manual: Power Door Mirrors

C

Kia Optima DL3 2019-2026 Service and Repair Manual: Evaporator Temperature Sensor

Description and operation Description The evaporator temperature sensor will detect the evaporator core temperature and interrupt compressor relay power in order to prevent evaporator from freezing by excessive cooling. The evaporator temperature sensor has the Negative Temperature Coefficient (NTC).

Categories

- Manuals Home

- Kia Optima Owners Manual

- Kia Optima Service Manual

- Steering System

- Rear Bumper Assembly

- External Amp

- New on site

- Most important about car